Composite environment-friendly high-flame-retardant filling rope for flame-retardant fire-resistant cable and preparation method thereof

A kind of flame retardant and fire-resistant, composite technology, applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problem of no flame retardant, poor radiation resistance, etc., to improve flame retardant and fire resistance, flame retardant performance High and Contributing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Raw material preparation

[0047] Waste clothes, old quilts, etc. are purchased in the market. These raw materials are polyester chemical fibers, pure cotton, polyester-cotton blends and a small amount of linen products.

[0048] (2) Equipment procurement

[0049] ①Tearing and crushing machine: Qingdao Hongda Textile Machinery Co., Ltd.;

[0050] ② Coarse opening and large warehouse blending machine: Changshu Tianli Nonwoven Equipment Co., Ltd., Qingdao Hongda Textile Co., Ltd.;

[0051] ③ Carding machine: Changzhou Jinyang Textile Machinery Co., Ltd., Qingdao Qingxi Xinhua Textile Machinery Co., Ltd.;

[0052] ④Warping machine: Jiangyin Sifang Machinery New Technology Manufacturing Co., Ltd., Sheyang Dongxiang Textile Machinery Co., Ltd.;

[0053] ⑤ Sizing machine: Sheyang Zhiqiang Textile Machinery Co., Ltd., Yancheng Huate Textile Machinery Co., Ltd.;

[0054] ⑥Sanding machine: Changzhou Wujin Guangyu Flower Roller Machinery Co., Ltd., Jiangyin Lineng Machine...

Embodiment 2

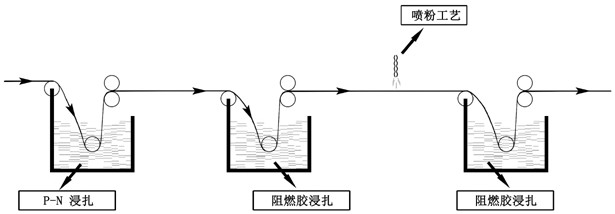

[0087] Such as figure 1 As shown, the preparation method of the composite environmentally friendly high flame-retardant filling rope for flame-retardant and fire-resistant cables comprises the following steps:

[0088] aUse a high-speed shredder (above 50kw, speed 80 rpm, alloy material for cutting knife) to pass waste fabrics, quilts, etc. of different sizes through the shredder → produce small pieces, slender Shape blocks and small cotton balls → use 10kw coarse opener (up to 1000kg / h output, fiber length 0.5-10mm) process (to produce finer fibrous short filaments) → Dacang cotton blending process (to produce The fibers are fully fluffy) → fine opening process (further flowering, opening and separation) → air pressure cotton box collection → 186F carding machine carding into a web → air spinning to produce roving (2-3 counts). It replaces the use of crushers in the current process (the cloth is fragile and easy to form a ball) → blue and white machine → multi-compartment bl...

Embodiment 3

[0145] Composite environment-friendly high flame-retardant filling rope for flame-retardant and fire-resistant cables, including roving made of waste polyester cotton as the filling rope base material, phosphorus-nitrogen water-based flame-retardant powder is dispersed inside the base material, and the base material is coated with Covered with the first Mg(OH) 2 Flame retardant adhesive layer, the Mg(OH) 2 A powdery flame retardant layer is sprayed on the outside of the flame retardant adhesive layer, and the outside of the powdery flame retardant layer is coated with a second Mg(OH) 2 flame retardant adhesive layer, the second Mg(OH) 2 The surface of the flame retardant adhesive layer is coated with a ceramic refractory layer.

[0146] The waste polyester cotton includes waste clothes and / or quilts.

[0147]The rovings are 2-3 rovings with a grammage of 0.2-0.4g / m, an elongation>15%, and a tensile force>0.5N / 10cm.

[0148] The phosphorus-nitrogen water-based flame retarda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com