Method for efficiently preparing biodiesel by enzymatic method

A biodiesel, high-efficiency technology, applied in the direction of biofuel, fermentation, etc., can solve the problem of limited source of biodiesel raw materials, achieve good economic and environmental benefits, shorten the reaction time, and reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

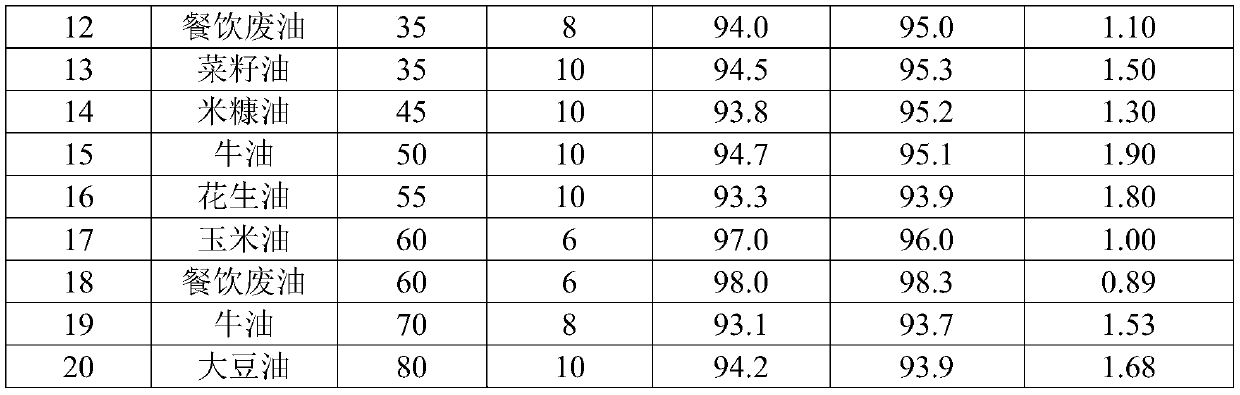

Embodiment 1

[0029] The soybean oil is saponified into soybean oil fatty acid, which is then added to the soybean oil, and the content of the fatty acid in the soybean oil is controlled to be 7%. Add soybean oil and methanol containing 7% fatty acid to a 250mL Erlenmeyer flask according to a molar ratio of 1:1, add MAS 1 lipase based on 30 enzyme activity units per unit raw material oil quality, and in a water bath at 40°C, the reaction speed is 200rpm, methanol was added every 2 hours, and after 6 hours of reaction, the conversion rate of triglyceride reached 96.0%, the yield of fatty acid methyl ester reached 98.0%, and the acid value dropped to 0.60 mg / g.

Embodiment 2

[0031] The tallow is saponified into fatty acids, which are then added to the tallow, and the fatty acid content in the tallow is controlled to be 8%. Add tallow and methanol containing 8% fatty acid to a 250mL Erlenmeyer flask according to a molar ratio of 1:1, add MAS 1 lipase based on 30 enzyme activity units per unit raw material oil quality, and in a water bath at 50°C, the reaction speed is 200rpm, methanol was added every 2 hours, and after 6 hours of reaction, the conversion rate of triglyceride reached 98.0%, the yield of fatty acid methyl ester reached 98.0%, and the acid value decreased to 0.50 mg / g.

Embodiment 3

[0033] The peanut oil is saponified into peanut oil fatty acid, which is then added to the peanut oil, and the fatty acid content in the peanut oil is controlled to be 10%. Add peanut oil and methanol containing 10% fatty acid to a 250mL Erlenmeyer flask at a molar ratio of 1:1, add 30 enzyme activity units of MAS 1 lipase based on the unit raw material oil mass, and place in a water bath at 40°C with a reaction speed of 200rpm , adding methanol every 2 hours, after 6 hours of reaction, the conversion rate of triglycerides reached 96.5%, the yield of fatty acid methyl esters reached 97.0%, and the acid value was reduced to 0.80 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com