Method for directly reducing materials by using rotary hearth furnace

A rotary hearth furnace and material technology, which is used in rotary drum furnaces, furnaces, furnace types, etc., can solve the problems of powder materials must be agglomerated, high calorific value gas dependence, etc., and achieve the effect of increasing the charging amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

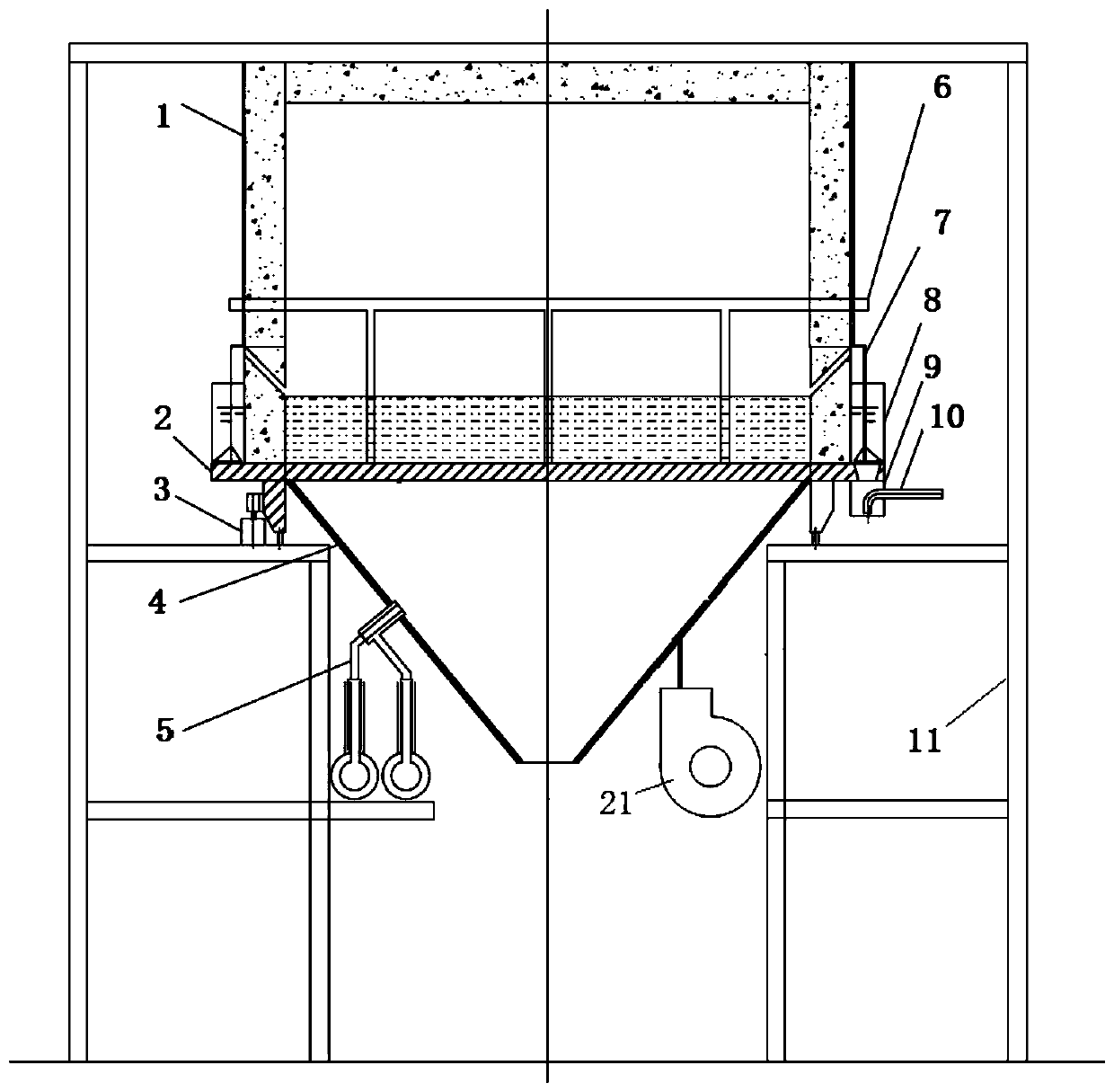

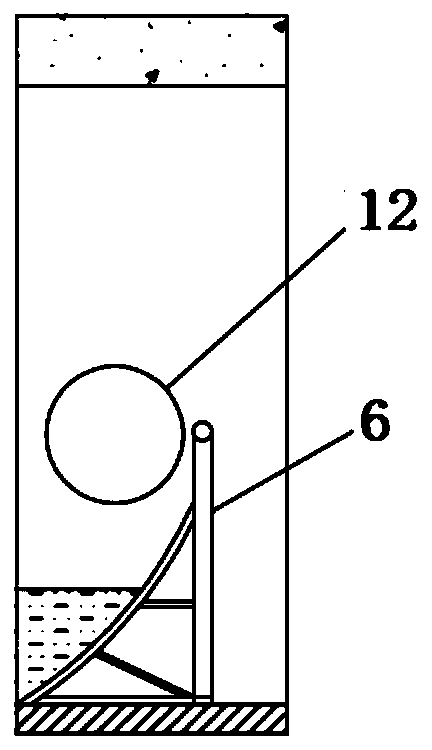

[0042] This embodiment discloses a rotary hearth furnace, such as figure 1 , figure 2 , Figure 4~6 As shown, it includes a rotary hearth furnace body 19, a water seal unit and an air supply unit. The rotary furnace body includes an annular fixed furnace body and an annular rotating furnace bottom 2 located below the annular fixed furnace body 1. The annular fixed furnace body 1 and the annular The rotating furnace bottom 2 is sealed by a water seal unit; the bottom end of the annular rotating furnace bottom 2 is a bottom plate with holes on which the mixture is laid. The unit rotates with the annular rotating furnace bottom 2 .

[0043] Specifically, the rotary hearth furnace includes a rotary hearth furnace body 19, a water seal unit and an air supply unit. The rotary hearth furnace body 19 includes an annular fixed furnace body 1 and an annular rotating hearth 2, and the annular rotating hearth 2 is arranged on an annular fixed furnace body. Directly below the furnace b...

Embodiment 2

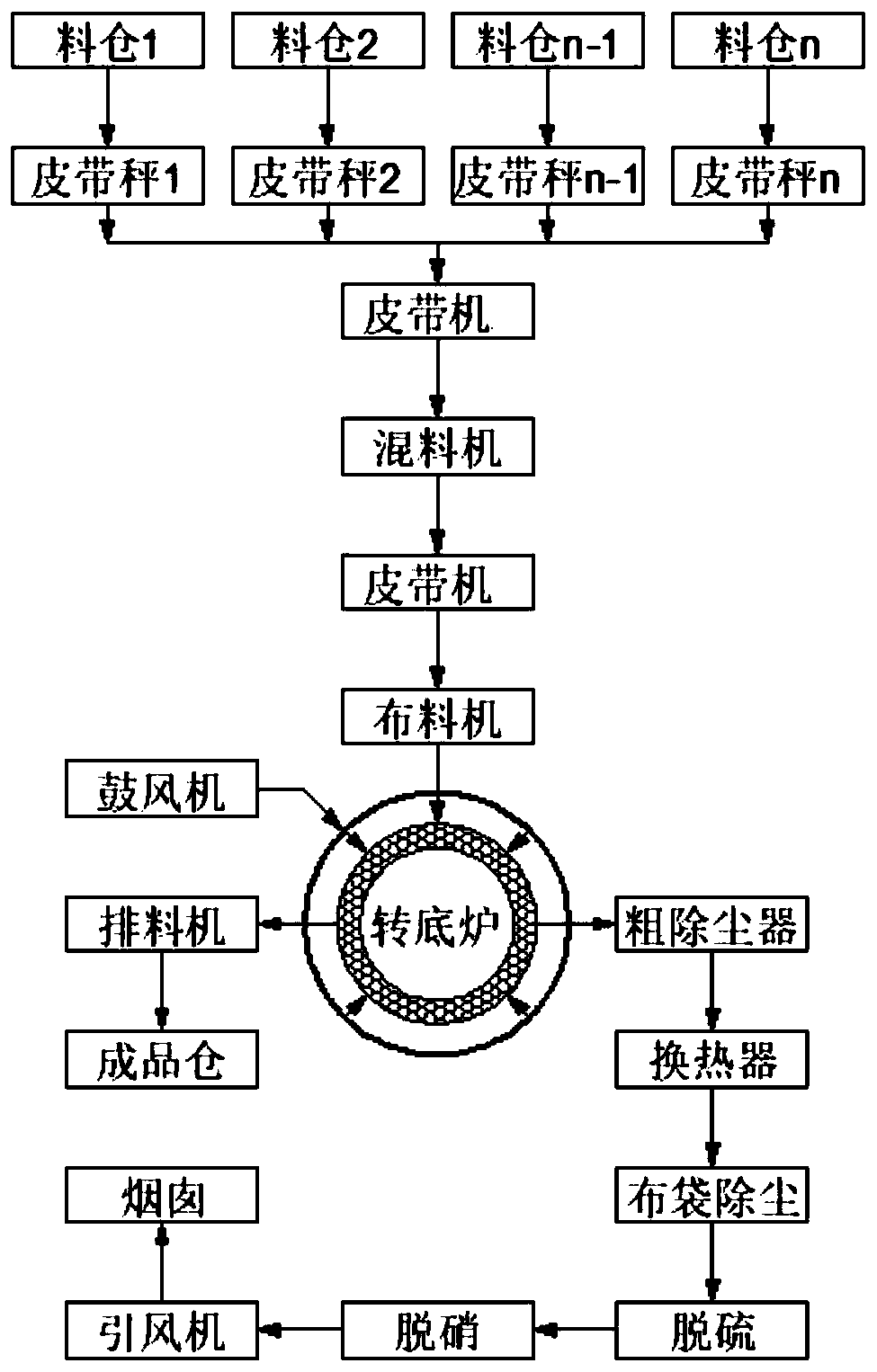

[0073] This embodiment provides a method of direct reduction using a rotary hearth furnace, using the rotary hearth furnace in Example 1, such as image 3 As shown, when the air distribution wind box 4 is connected with the blower, the method for utilizing the rotary hearth furnace for direct reduction comprises the following steps:

[0074] Step 1. Load various materials in silo 1 to silo n, weigh and feed them to belt conveyor P through belt scale 1 to belt scale n, and transport them to the mixer through belt conveyor P for mixing and mixing. The final mixture is transported to the conical roller distributor 18 of the rotary hearth furnace by the belt conveyor S, and is evenly distributed to the hearth of the rotary hearth furnace by the conical roller distributor 18;

[0075] Step 2, the combustion-supporting gas enters the mixture layer through the annular air distribution pipe 13, the air distribution bellows 4 and the first hole, and simultaneously the gas enters the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com