Preparation method and application of magnesium aluminum hydrotalcite flame retardant modified jute fabric with different anion intercalation

A technology of magnesium-aluminum hydrotalcite and anion intercalation, which is used in flame-retardant fibers, plant fibers, textiles and paper making, etc., can solve the problems of large smoke generation, easy dripping, toxicity, etc., and achieves excellent flame retardant performance. , Improve the flame retardant effect, the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

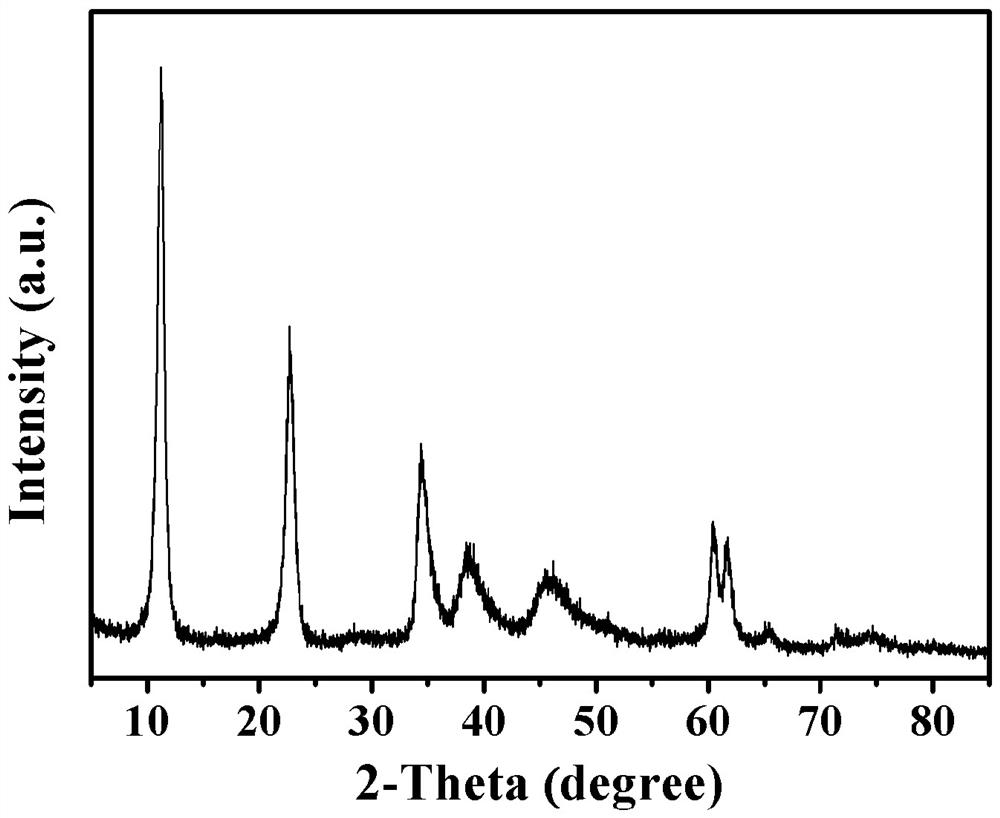

[0035] A method of reconstituting CO by roasting in this embodiment 3 2- The method for intercalating magnesium-aluminum LDH flame retardant modified jute fabric is specifically carried out according to the following steps:

[0036] (1) Preparation of Cl by co-precipitation method - Intercalated MgAl LDH: According to Mg 2+ : Al 3+ The molar ratio is 3:1, the total ion concentration is 0.5mol / L, and 700mL MgCl is prepared 2 , AlCl 3 mixed solution, and then prepare 200 mL of 6 mol / L NaOH solution. The NaOH solution was slowly added dropwise to the mixed solution until the pH was changed to 9.5, and the LDH colloid was finally obtained. After standing and aging for 2 hours, the solution was filtered, and the filtrate was placed in an oven at 110° C., and the LDH block solid was obtained after complete drying. Grind it into powder and use it.

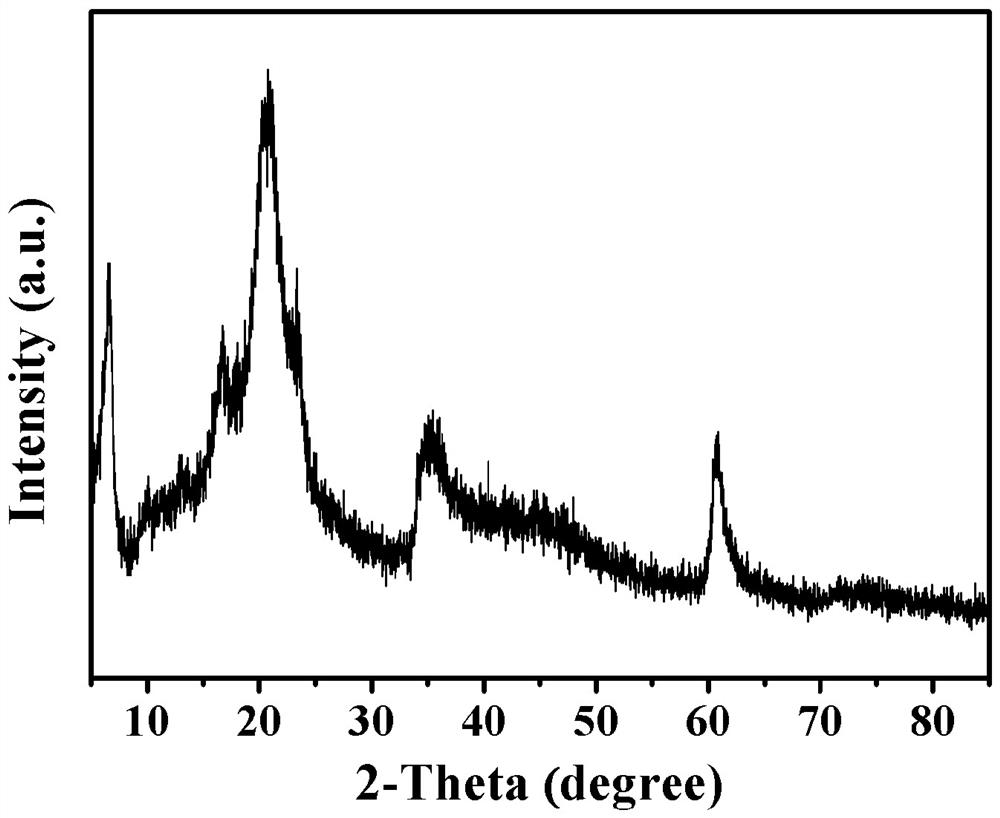

[0037] (2) Preparation of layered double metal oxide (LDO) by calcination method: LDH ground into powder is put into a muffle fu...

Embodiment 2

[0045] A method of reconstituting CO by roasting in this embodiment 3 2- The method for intercalating magnesium-aluminum LDH flame retardant modified jute fabric is specifically carried out according to the following steps:

[0046] (1) Preparation of Cl by co-precipitation method - Intercalated MgAl LDH: According to Mg 2+ : Al 3+ The molar ratio is 3:1, the total ion concentration is 0.5mol / L, and 700mL MgCl is prepared 2 , AlCl 3 mixed solution, and then prepare 200 mL of 6 mol / L NaOH solution. The NaOH solution was slowly added dropwise to the mixed solution until the pH was changed to 9.5, and the LDH colloid was finally obtained. After standing and aging for 2 hours, the solution was filtered, and the filtrate was placed in an oven at 110° C., and the LDH block solid was obtained after complete drying. Grind it into powder and use it.

[0047] (2) Preparation of layered double metal oxide (LDO) by calcination method: LDH ground into powder is put into a muffle fu...

Embodiment 3

[0052] A method of reconstituting CO by roasting in this embodiment 3 2- The method for intercalating magnesium-aluminum LDH flame retardant modified jute fabric is specifically carried out according to the following steps:

[0053] (1) Preparation of Cl by co-precipitation method - Intercalated MgAl LDH: According to Mg 2+ : Al 3+ The molar ratio is 3:1, the total ion concentration is 0.5mol / L, and 700mL MgCl is prepared 2 , AlCl 3 mixed solution, and then prepare 200 mL of 6 mol / L NaOH solution. The NaOH solution was slowly added dropwise to the mixed solution until the pH was changed to 9.5, and the LDH colloid was finally obtained. After standing and aging for 2 hours, the solution was filtered, and the filtrate was placed in an oven at 110° C., and the LDH block solid was obtained after complete drying. Grind it into powder and use it.

[0054] (2) Preparation of layered double metal oxide (LDO) by calcination method: LDH ground into powder is put into a muffle fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com