A preparation method of slow-release polyurethane mesh carrier and its application in chemical wastewater treatment

A chemical wastewater, polyurethane technology, applied in water/sewage treatment, biological water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of poor biodegradation resistance, polyvinyl alcohol poisoning, etc., achieve low microbial toxicity, physicochemical Stabilizing, improving water absorption and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

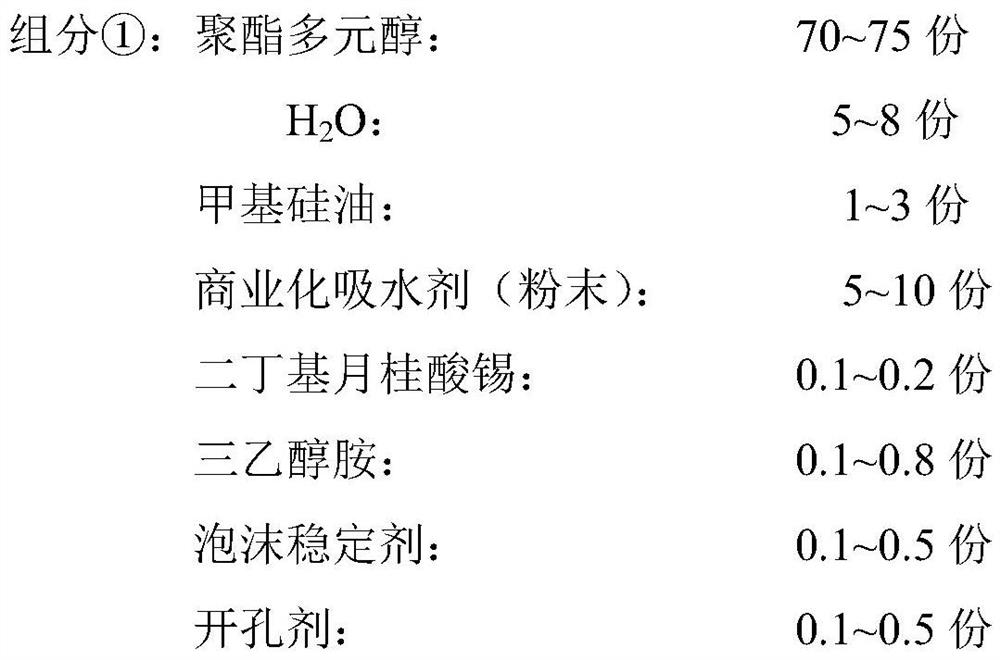

[0042] Step 1, the preparation of the polyurethane foam carrier of net shape open cell water absorption performance:

[0043]

[0044] After mixing the above-mentioned raw materials in sequence, mechanically stir (6000r / min) at 35-45°C for 3-5 minutes until uniform to obtain Component ①.

[0045] Component ②: Polyether 330: 20-35 parts

[0046] Diphenylmethane diisocyanate: 50-65 parts.

[0047] After mixing the above raw materials in sequence, stir (6000r / min) at 35-45°C for 2 minutes until uniform, and obtain Component ②.

[0048] Mix component ① with component ②, stir mechanically (200r / min), stop stirring after 10-30 seconds after foaming, foam at room temperature for 12-24 hours, and obtain a polyurethane foam carrier with net-shaped open cells and water-absorbing properties. Then cut into cuboid small pieces with a specification of 20×15×15mm.

[0049] Step 2, mix guar gum (GG) with deionized water, dissolve it completely at 80°C, let it stand and cool to 50°C, add...

Embodiment 2

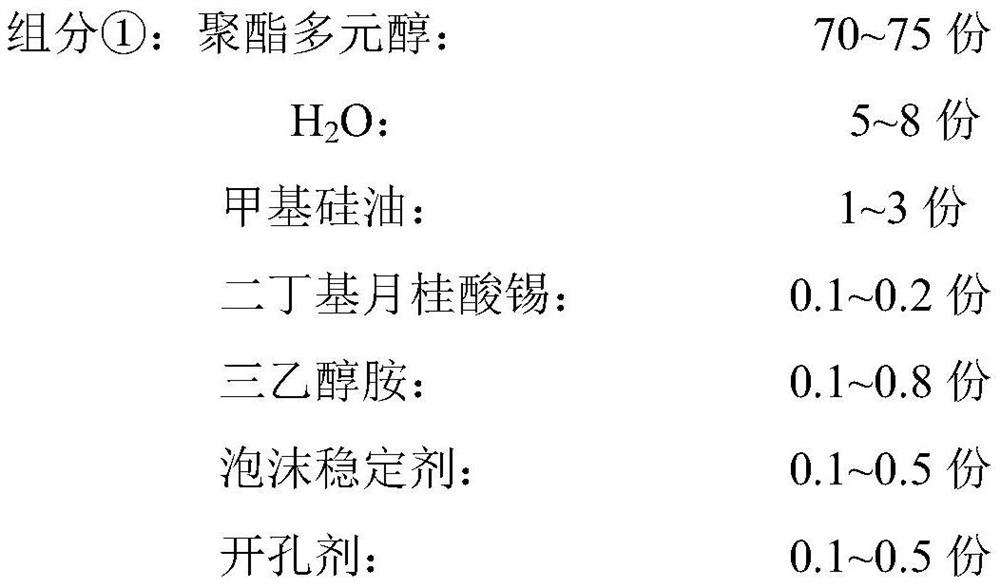

[0075] Step 1, the preparation of the polyurethane foam carrier of net shape open cell water absorption performance:

[0076]

[0077] After mixing the above-mentioned raw materials in sequence, mechanically stir (6000r / min) at 35-45°C for 3-5 minutes until uniform to obtain Component ①.

[0078] Component ②: Polyether 330: 20-35 parts

[0079] Diphenylmethane diisocyanate: 50-65 parts.

[0080] After mixing the above raw materials in sequence, stir (6000r / min) at 35-45°C for 2 minutes until uniform, and obtain Component ②.

[0081] Mix component ① with component ②, stir mechanically (200r / min), stop stirring after 10-30 seconds after foaming, foam at room temperature for 12-24 hours, and obtain a polyurethane foam carrier with net-shaped open cells and water-absorbing properties. Then cut into cuboid small pieces with a specification of 20×15×15mm.

[0082] Step 2, mix sodium alginate (SA) with deionized water, dissolve it completely at 90°C, let it stand and cool to 40...

Embodiment 3

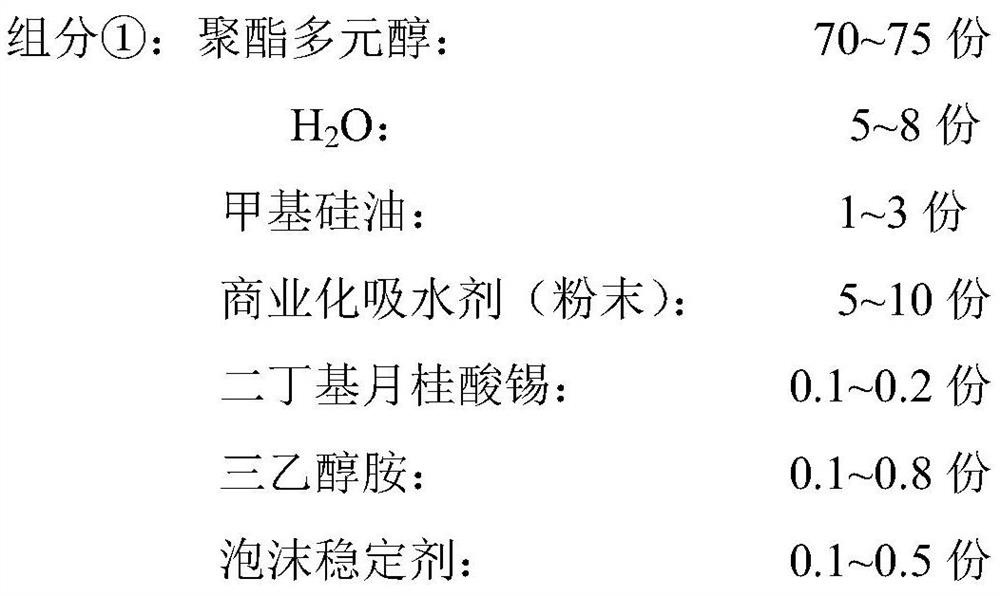

[0086] Step 1, the preparation of the polyurethane foam carrier of net shape open cell water absorption performance:

[0087]

[0088] After mixing the above-mentioned raw materials in sequence, mechanically stir (6000r / min) at 35-45°C for 3-5 minutes until uniform to obtain Component ①.

[0089] Component ②: Polyether 330: 20-35 parts

[0090] Diphenylmethane diisocyanate: 50-65 parts.

[0091] After mixing the above raw materials in sequence, stir (6000r / min) at 35-45°C for 2 minutes until uniform, and obtain Component ②.

[0092] Mix component ① with component ②, stir mechanically (200r / min), stop stirring after 10-30 seconds after foaming, foam at room temperature for 12-24 hours, and obtain a polyurethane foam carrier with net-shaped open cells and water-absorbing properties. Then cut into cuboid small pieces with a specification of 20×15×15mm.

[0093] Step 2, mix triacetyl cellulose (TCA) with deionized water, dissolve completely at 90°C, let it stand and cool to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com