Three-phase equilibrium efficient and uniform-temperature hot-blast air tunnel furnace drying device

A three-phase balance, hot air tunnel technology, applied in heating devices, drying, dryers and other directions, can solve the problems of uneven temperature of the conveyor belt, high manufacturing cost, low heat energy utilization efficiency, etc., and achieve a simple, novel and reasonable structure. , convenient transportation and installation, high thermal energy utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

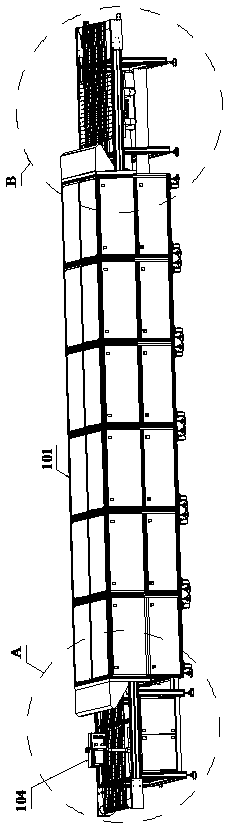

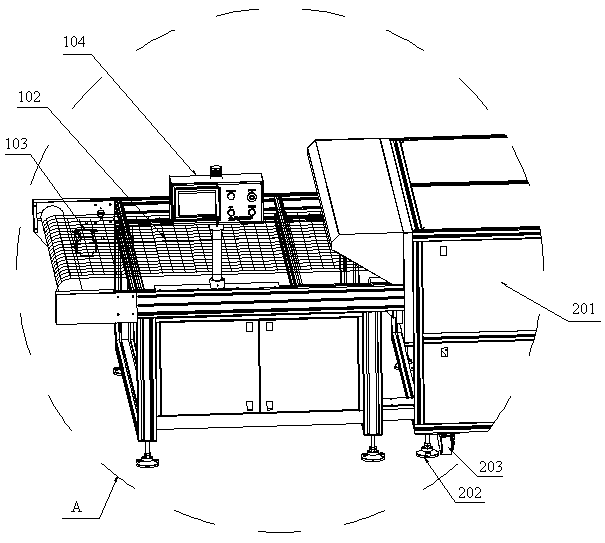

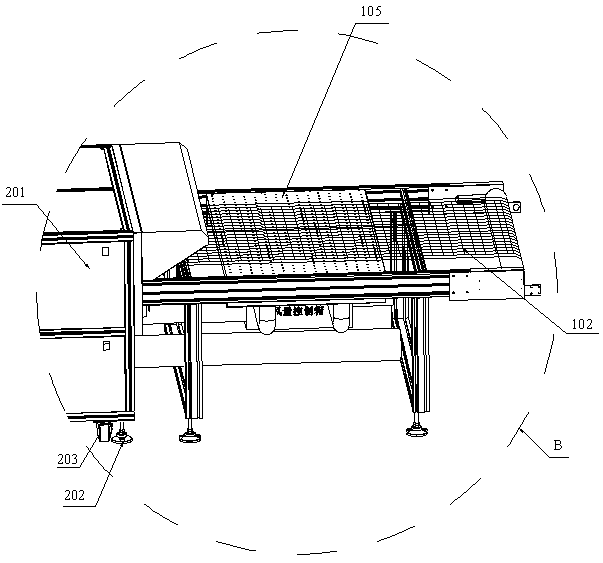

[0026] refer to Figure 1 to Figure 12 , propose an embodiment of a three-phase balanced, high-efficiency and uniform temperature hot air tunnel furnace drying device of the present invention, which can bake printed cloth, including a module composed of several drying modules 101 spliced together Drying line with chemical structure, conveyor belt 102 that can transmit workpieces throughout the entire drying line, drive motor 103 that drives conveyor belt 102 to work, control panel 104 that can control the work of hot air tunnel furnace drying device, and is located at the tail end of conveyor belt 102 The workpiece heat dissipation device 105 can blow the workpiece to play a role in heat dissipation; the drying module 101 includes a standard drying module, a moisture removal and heat recovery drying module with func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com