Thermoelectric material and preparation method thereof

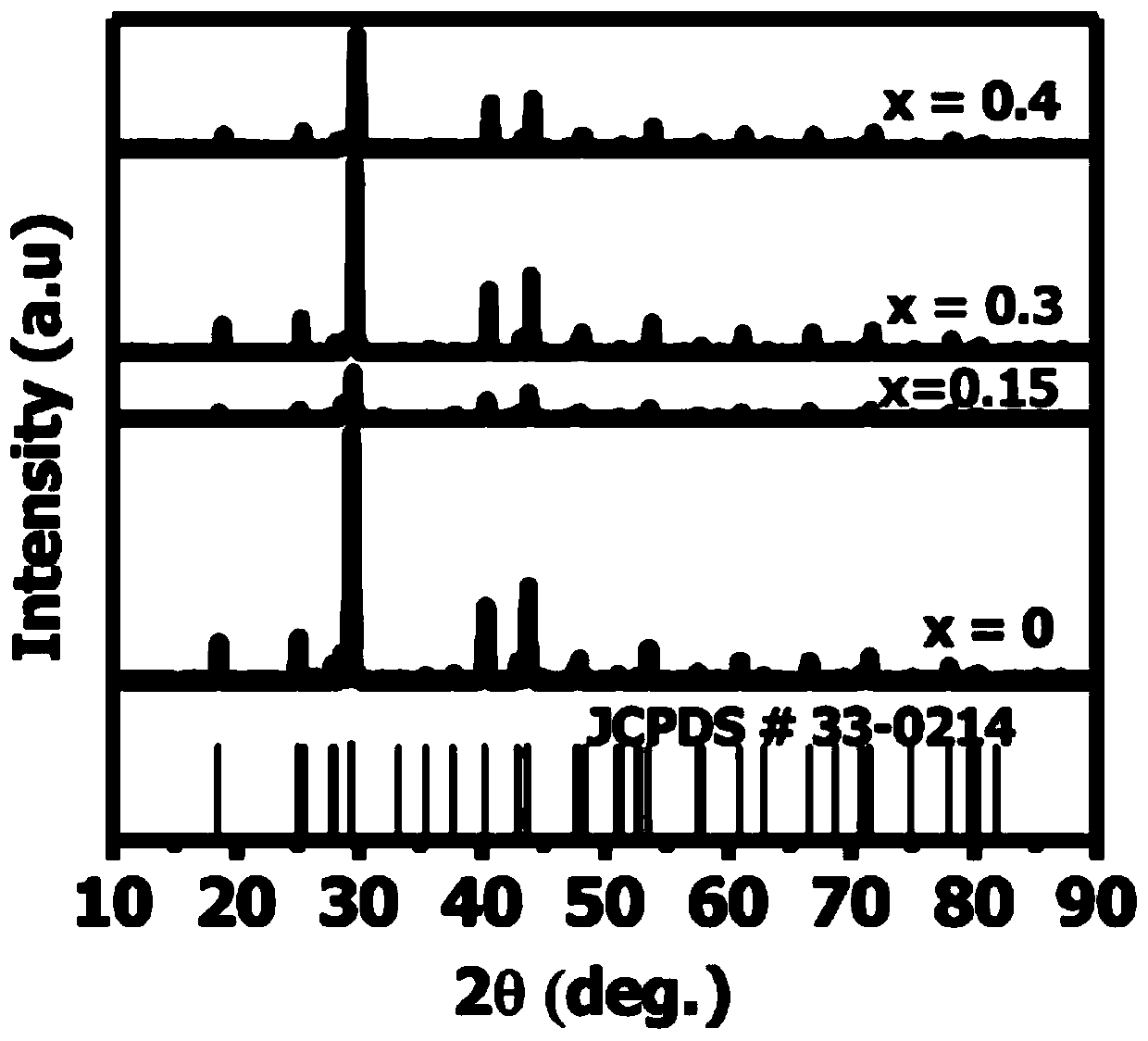

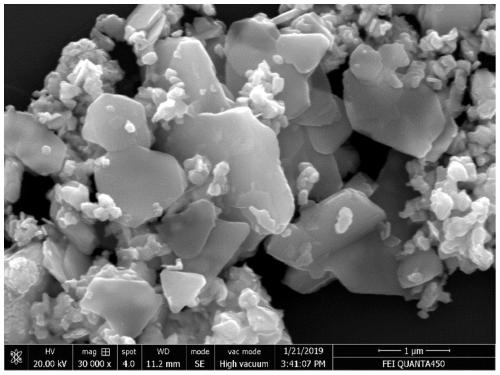

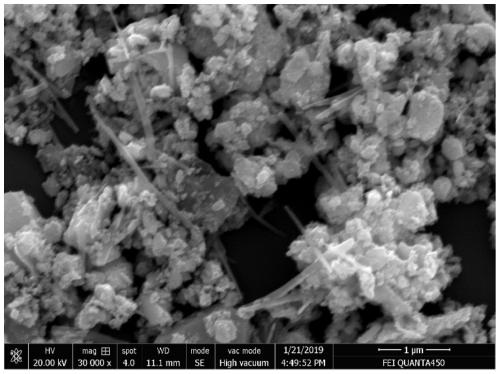

A technology of thermoelectric materials and raw materials, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., which can solve the problems of poor thermoelectric performance of thermoelectric materials, damage to the crystal structure of bismuth selenide, and affect the thermoelectric properties of materials, etc. , to achieve the effects of reducing ionized impurity scattering, high Seebeck coefficient, and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of thermoelectric material of this embodiment, comprises the raw material composition of following molar ratio:

[0040] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 .5H 2 O, 98%) 0.8mmol

[0041] Selenium powder (99%) 1.5mmol

[0042] Cerium nitrate hexahydrate (Ce(NO 3 ) 3 .6H 2 O, 99.99%) 0.2mmol

[0043] Ethanolamine (≥99.0%) 0.59mmol

[0044] Anhydrous 2-methoxyethanol (99.8%) 0.91 mmol.

[0045] The preparation method of the thermoelectric material of this embodiment includes the following steps:

[0046] S1 Mix anhydrous 2-methoxyethanol and ethanolamine with selenium powder, and stir continuously for 15 minutes to obtain a mixture;

[0047] S2 will Bi(NO 3 ) 3 .5H 2 O and Ce(NO 3 )3 .6H 2 O was added to the mixture of step S1 respectively, stirred for 3h to obtain a suspension;

[0048] S3 Transfer the suspension in step S2 to a 50ml Teflon autoclave, and react overnight at 180°C to obtain a black precipitate;

[0049] S4 Collect the black p...

Embodiment 2

[0051] The thermoelectric material of this embodiment includes the following molar ratios of raw material components:

[0052] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 .5H 2 O, 98%) 0.85mmol

[0053] Selenium powder (99%) 1.35mmol

[0054] Cerium nitrate hexahydrate (Ce(NO 3 ) 3 .6H 2 O, 99.99%) 0.15mmol

[0055] Ethanolamine (≥99.0%) 0.53mmol

[0056] 2-Methoxyethanol (99.8%) 0.82 mmol.

[0057] The preparation method of the thermoelectric material of this embodiment includes the following steps:

[0058] S1 Mix anhydrous 2-methoxyethanol and ethanolamine with selenium powder, and stir continuously for 30 minutes to obtain a mixture;

[0059] S2 will Bi(NO 3 ) 3 .5H 2 O and Ce(NO 3 ) 3 .6H 2 O was added to the mixture of step S1 respectively, stirred for 2.5h to obtain a suspension;

[0060] S3 Transfer the suspension in step S2 to a 50ml Teflon autoclave, and react overnight at 200°C to obtain a black precipitate;

[0061] S4 Collect the black precipitate ...

Embodiment 3

[0063] The thermoelectric material of this embodiment includes the following molar ratios of raw material components:

[0064] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 .5H 2 O, 98%) 0.925mmol

[0065] Selenium powder (99%) 1.65mmol

[0066] Cerium nitrate hexahydrate (Ce(NO 3 ) 3 .6H 2 O, 99.99%) 0.075mmol

[0067] Ethanolamine (≥99.0%) 0.65mmol

[0068] 2-Methoxyethanol (99.8%) 1 mmol.

[0069] The preparation method of the thermoelectric material of this embodiment includes the following steps:

[0070] S1 Mix anhydrous 2-methoxyethanol and ethanolamine with selenium powder, and stir continuously for 10 minutes to obtain a mixture;

[0071] S2 will Bi(NO 3 ) 3 .5H 2 O and Ce(NO 3 ) 3 .6H 2 O was added to the mixture of step S1 respectively, stirred for 2h to obtain a suspension;

[0072] S3 Transfer the suspension in step S2 to a 50ml Teflon autoclave, and react overnight at 170°C to obtain a black precipitate;

[0073] S4 Collect the black precipitate fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com