Cascade air source ultrahigh-temperature instantaneous sterilization device and method

An ultra-high temperature instant sterilization device technology, applied in the field of electrical appliances, can solve the problems of high energy consumption and non-energy saving, and achieve the effects of large energy saving potential, large cooling capacity, and reduced power consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

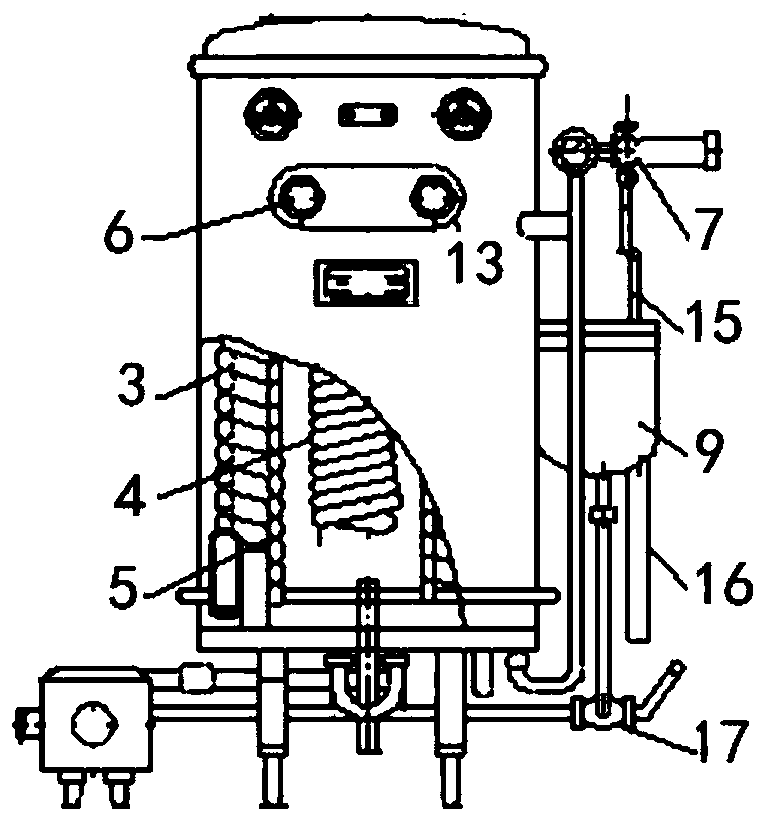

[0037] Embodiment 1: as shown in Figure 1, figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, the cascade air source ultra-high temperature instantaneous sterilization device includes a feeding butterfly valve 1, a feeding pump 2, a double-set coil 3, a high-temperature coil 4, a high-temperature barrel 5, a thermometer 6, and a throttle valve 7. Discharge butterfly valve 8, circulating storage tank 9, steam inlet 10, first angle stop valve 11, second angle stop valve 12, pressure gauge 13, temperature gauge 14, coil pipe 15, overflow pipe 16, U-shaped pipe 17, drain port 18, evaporator 19, low-temperature compressor 20, condenser 21, first throttle valve 22, evaporative condenser 23, high-temperature compressor 24, condenser 25, second throttle valve 26, high-temperature extinguishing Bacteria tank 27, liquid storage tank 28.

[0038] Cascade air source ultra-high temperature instantaneous sterilization device, such as figure 2 , image 3 As shown, the ...

Embodiment 2

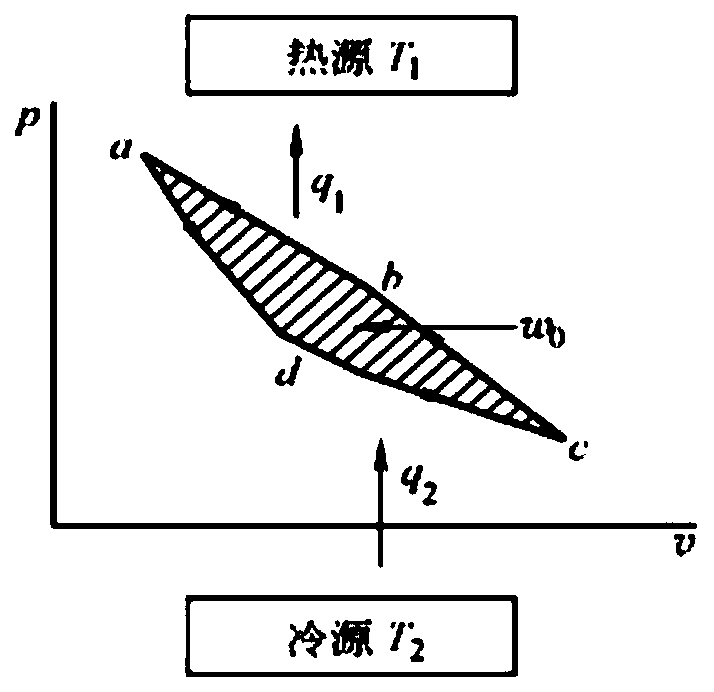

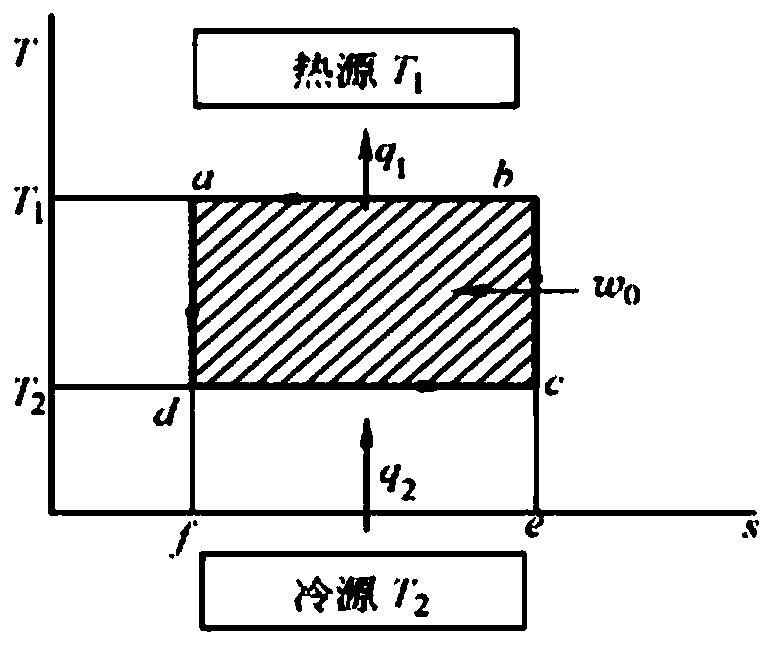

[0048] Embodiment 2: as shown in Figure 1, figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the cascade air source ultra-high temperature instantaneous sterilization device and method, its heat pump principle is based on the basic principle of the reverse Carnot cycle: the low-temperature and high-pressure liquid refrigerant becomes a low-temperature and low-pressure liquid refrigerant after throttling treatment by the expansion mechanism, and enters the Evaporation and heat absorption in the air exchanger absorbs a large amount of heat Q from the air 2 The refrigerant after evaporating and absorbing heat enters the compressor in a gaseous state, and after being compressed, it becomes a high-temperature and high-pressure refrigerant (the heat contained in the refrigerant is divided into two parts at this time: one part is the heat Q absorbed from the air 2 , part of which is the heat Q converted by the electrical energy input into the compressor when com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com