Composite type fibrous additive for promoting growth performance of laying hens

A growth performance, composite technology, applied in the direction of bacteria, lactobacilli, etc. used in food processing and food preparation, can solve the problems of fiber mycotoxins, etc., and achieve the effect of reducing the ratio of egg to material, satisfying satiety, and inhibiting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Numbering is 1-10 compound type fiber feed additive composition as shown in table 1, makes 10 kinds of compound fiber feed additives respectively, and the total amount of every kind of additive is 50kg, specifically each component raw material is placed in Fully mixed in a high-speed mixer to obtain samples of each compound fiber feed additive.

[0018] Table 1 The proportioning ratio of each component of composite fiber additive

[0019]

[0020] Each numbered additive is prepared according to the raw material formula in Table 1, and is a composite fiber additive. Then it is added to the basal diet of laying hens at 1% by mass for feeding. For each numbering group, 64 20-week-old, similar-weight, and healthy adult Hai-Line brown roosters were selected for each group, and were randomly divided into 4 groups, with 4 replicates in each group and 4 chickens in each replicate. The metabolism test was carried out by the method of total collection of feces. In each repe...

Embodiment 2

[0029] The experiment adopts a single factor complete randomized block design, and 384 healthy Hailan brown laying hens with similar body weight at 60 days are randomly divided into 4 treatments (0, 0.8%, 1.0% and 1.2% of the composite fiber additive numbered 6 in Example 1), each treatment group had 24 repetitions, and each repetition had 4 chickens. Each treatment was fed with one experimental diet supplemented with compound fiber, the pre-test period was 1 week, and the rats were fed formally at 60 days old.

[0030] The experimental diet was prepared on the basis of referring to NY / T 33-2004 and NRC (1994), combined with the Hailan brown laying hen breeding manual, and the experiment used corn-soybean meal (powder) type diet (Table 2). Three-layer three-layer cages in a chicken house, with 4 chicken cages (50 cm×50 cm×45 cm) connected in each row, each cage as a repetition, 4 chickens per cage (96 chicken cages in total), each The repetitions were evenly distributed on th...

Embodiment 3

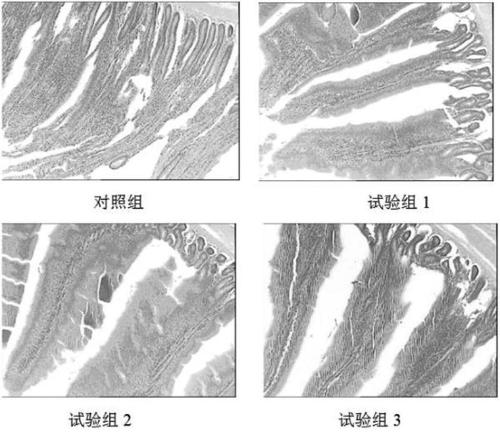

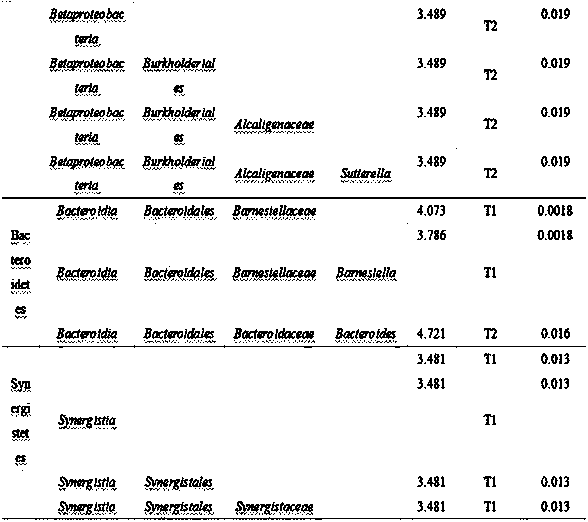

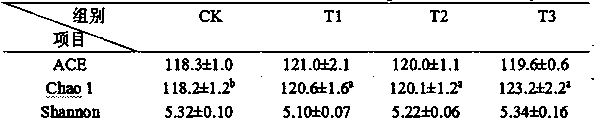

[0048] 384 one-day-old Hai-Line brown layer hens were randomly divided into 4 treatment groups, each treatment group had 24 replicates, and each replicate had 4 chickens. 4 treatment groups are test group 1, test group 2, test group 3, control group, in test group 1, test group 2, test group 3 add respectively 0.8%, 1.0%, 1.2% in embodiment 1 and number is 6 composite fiber additives. Feeding management is carried out in accordance with the "Standardized Hailan Brown Layer Feeding Standards".

[0049] 1. Detection of immunoglobulin content in laying hens

[0050] At the age of 120 and 180 days, 5 laying hens with similar body weight were selected from each treatment group, blood was collected from the heart, and the serum was separated for the determination of IgA, IgG and IgM.

[0051] It can be seen from Table 7 that in the 120d detection, the IgA content of the test group 3 was the highest at 623.16 μg / mL, and the test group 2 was 621.32 μg / mL. The difference between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com