A kind of hollow multi-shell material and its preparation method and application

A shell, hollow technology, applied in chemical instruments and methods, carbon monoxide, physical/chemical process catalysts, etc., to achieve the effects of simple and easy preparation method, large capacity and high reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

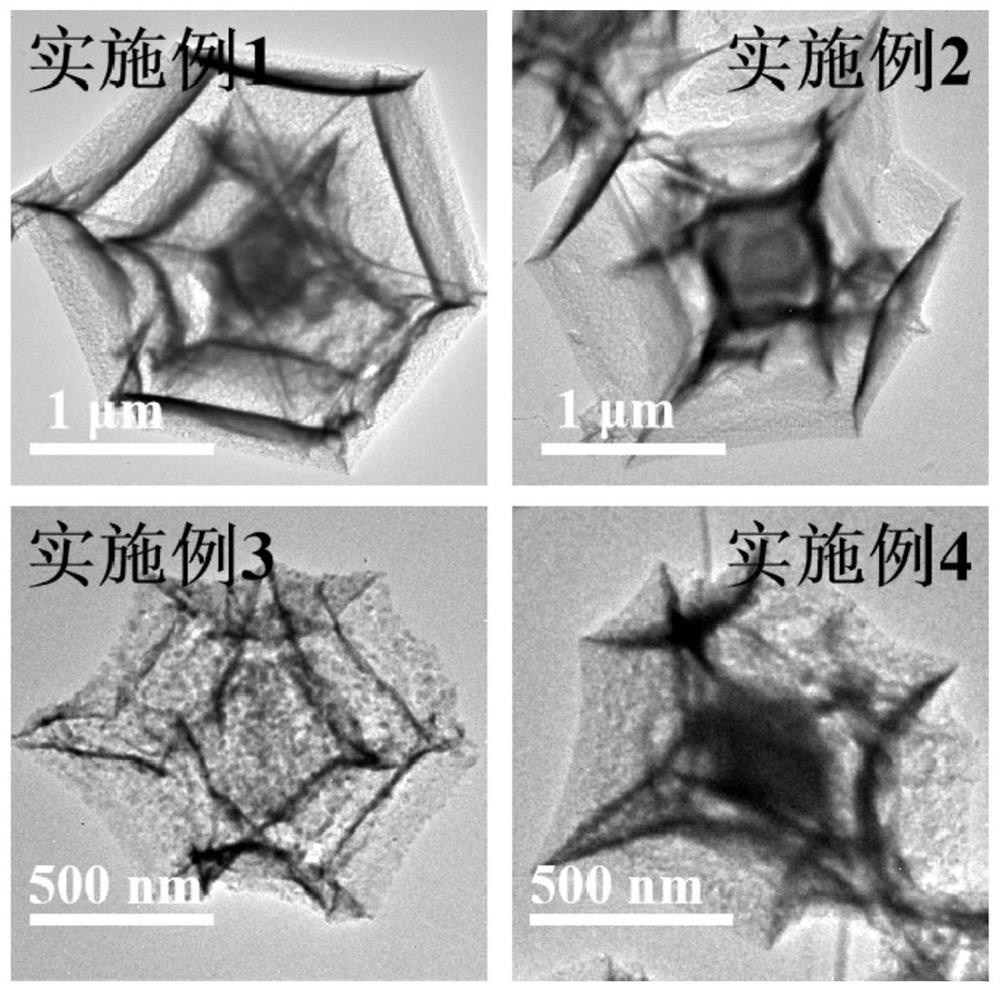

[0046] The invention provides a method for preparing a hollow multi-shell material, the preparation method comprising:

[0047] The metal-organic framework material was heated up to 425°C at a rate of 0.5°C / min in a tube furnace in a mixed atmosphere of oxygen and nitrogen at a volume ratio of 1:9, and held for 1 hour to obtain a hollow multi-shell material.

[0048] The preparation method of the metal-organic framework material is as follows: rapidly mixing the metal salt solution and the organic ligand solution with a molar ratio of 1:4, stirring for 2 minutes to obtain the mixture, and standing and aging at 40° C. for 30 hours.

[0049] Wherein, the metal salt solution is a methanol solution of cobalt chloride, and the organic ligand solution is a methanol solution of dimethylimidazole.

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that in this embodiment, the volume ratio of oxygen and nitrogen in the mixed atmosphere is 1:4.

Embodiment 3

[0053] The only difference between this example and Example 2 is that in this example, the aging temperature in the preparation method of the metal organic framework material is room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com