Refining method of guanidine nitrate

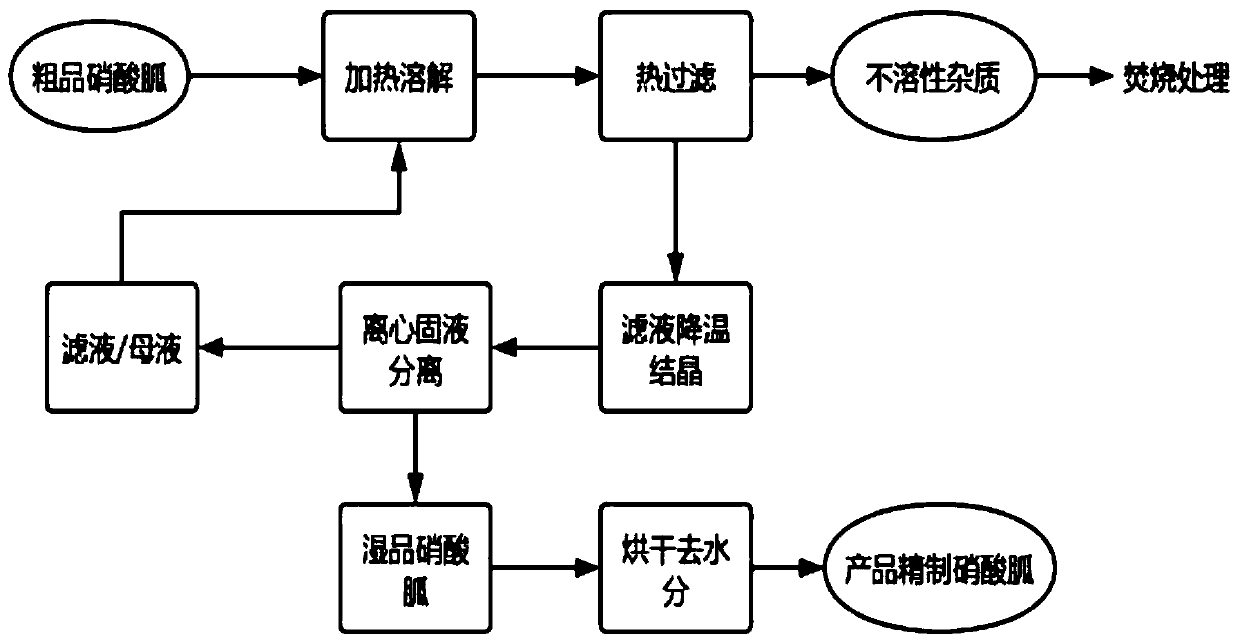

A refining method and technology of guanidine nitrate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low yield, low purity, less cycle times of mother liquor, high production cost, and high energy consumption, and achieve The effect of high product purity, stable product purity, and increased recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

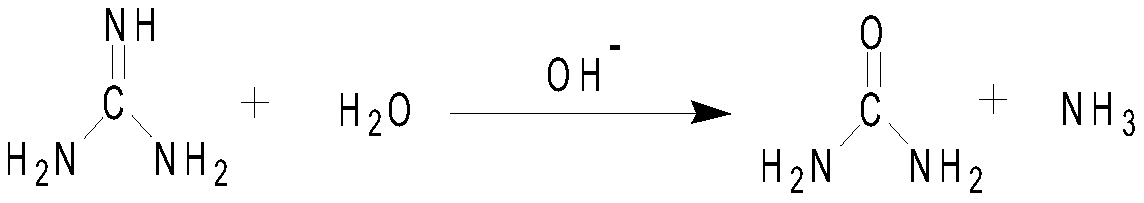

Problems solved by technology

Method used

Image

Examples

Embodiment 1

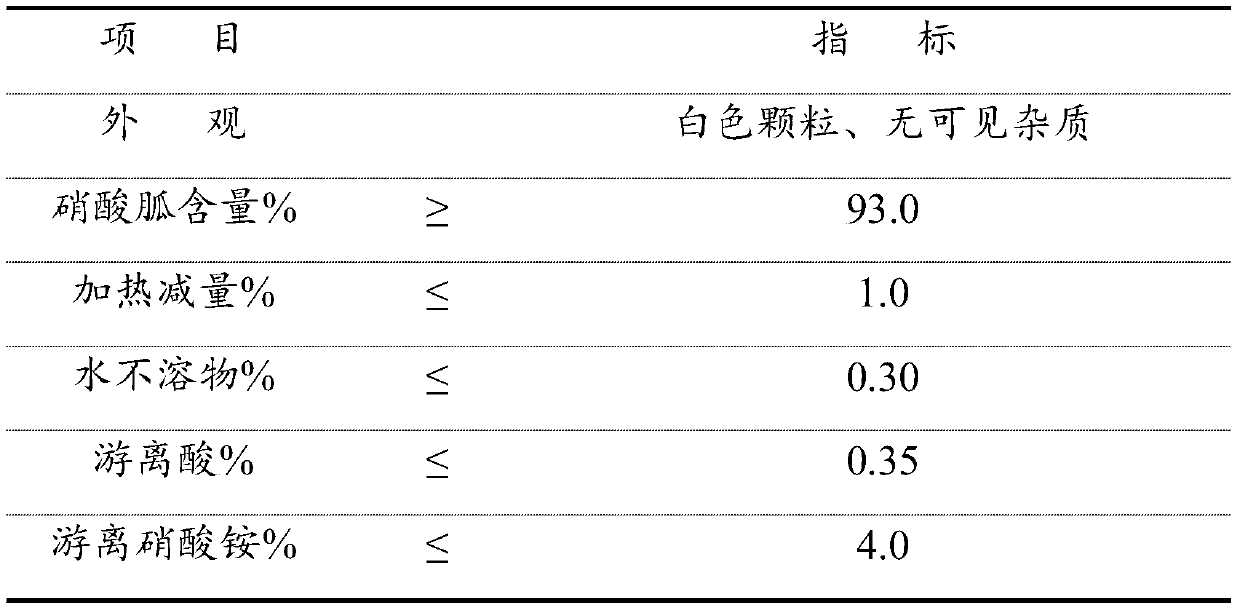

[0042] The various indexes of raw material crude product guanidine nitrate are as follows table 1:

[0043] Table 1

[0044]

[0045] Add 550g of distilled water and 264.0g of guanidine nitrate into a three-necked flask with mechanical stirring and a thermometer, start stirring and heating to dissolve; when the material is heated to 80°C, keep it warm at this temperature for 30min, at this time the material is white and turbid, and the system Slightly blue, after the heat preservation is over, take out the Buchner funnel that has been insulated in a water bath at 85°C, and filter the material at 80°C to remove water-insoluble matter. Crystallize and measure the pH value of the filtrate at the same time. When the temperature drops to 30°C, suction filter to obtain the filtrate and the product containing some water. The product is then dried in an oven set at 95°C for 2-3 hours to obtain refined guanidine nitrate ; And the mother liquor continues to be recycled in the next b...

Embodiment 2

[0048]Add 605g of mother liquor and 223g of guanidine nitrate obtained in Example 1 into a three-necked flask with mechanical stirring and a thermometer, stir and heat to dissolve; when the material is heated to 80°C, keep it for 30min at this temperature, and the material is white at this time The system is turbid, and the system is slightly blue. After the heat preservation is over, take out the Buchner funnel that has been insulated in a water bath at 85°C, and filter the material at 80°C to remove water-insoluble matter. After filtration, pour the filtrate back into the three-necked flask, and continue Stir slowly to cool down and crystallize, and measure the pH value of the filtrate at the same time. The filtrate cools down and crystallizes. When the temperature drops below 25°C, filter with suction to obtain the filtrate and product crystals. The product crystals are dried in an oven at 95°C for 2-3 hours and finally refined. Guanidine nitrate; and the mother liquor conti...

Embodiment 3

[0051] Add 617g of mother liquor and 223g of guanidine nitrate obtained in Example 2 into a three-necked flask with mechanical stirring and a thermometer, stir and heat to dissolve; when the material is heated to 80°C, it is kept at this temperature for 30min, and now the material is white The system is turbid, and the system is slightly blue. After the heat preservation is over, take out the Buchner funnel that has been insulated in a water bath at 85°C, and filter the material at 80°C to remove water-insoluble matter. After filtration, pour the filtrate back into the three-necked flask, and continue Stir slowly to cool down and crystallize, measure the pH value of the filtrate at the same time, the filtrate cools down and crystallizes, and when the temperature drops below 20°C, filter with suction to obtain the filtrate and product crystals, in which the product crystals are dried in an oven at 95°C for 2-3 hours and finally refined Guanidine nitrate; and the mother liquor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com