1-butene/ethylene/advanced alpha-olefin terpolymer as well as preparation method and application thereof

An olefin terpolymer and olefin polymerization technology, applied in the polymer field, can solve the problem of high flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

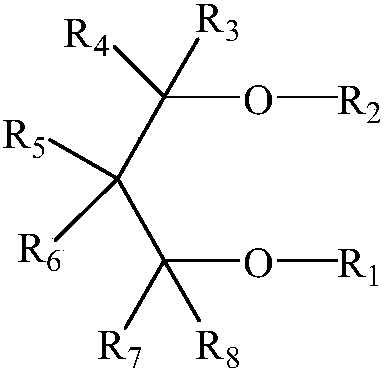

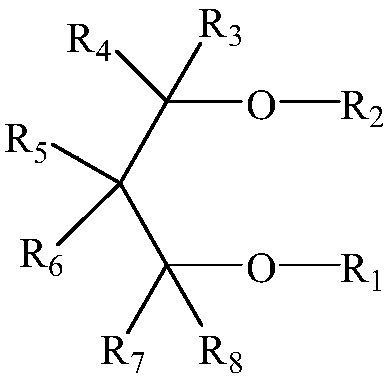

Method used

Image

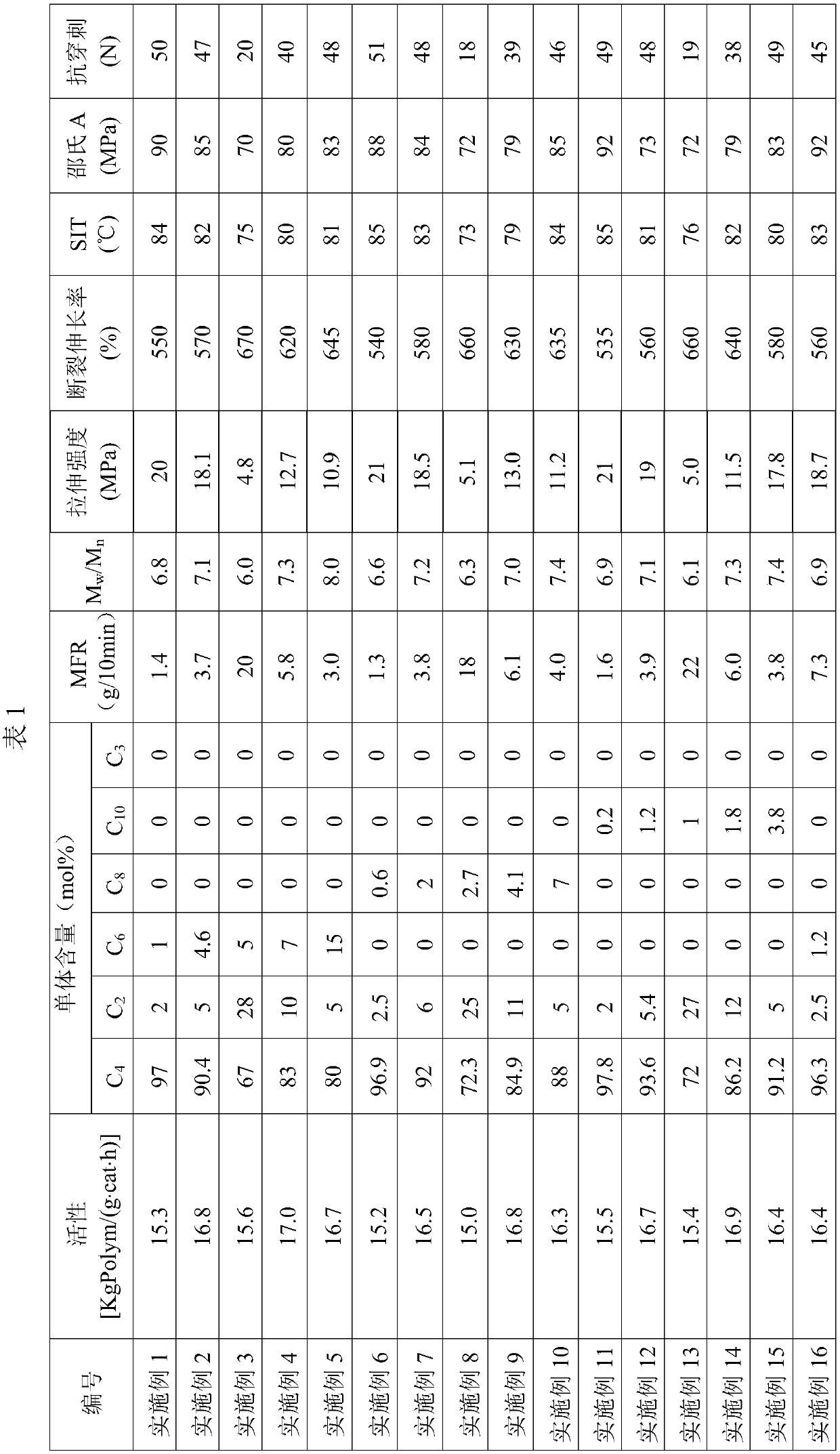

Examples

preparation example Construction

[0022] The preparation method of 1-butene / ethylene / higher α-olefin terpolymer provided by the invention comprises:

[0023] Mode (1): 1-butene, ethylene and a monomer mixture of higher α-olefins are subjected to olefin polymerization in the presence of a Ziegler-Natta catalyst system, and the monomer mixture contains 50-99mol% of 1-butane Olefin, 0.1-30mol% ethylene and 0.1-20mol% higher α-olefin, the conditions of the olefin polymerization reaction make the obtained 1-butene / ethylene / higher α-olefin terpolymer at 190 ℃, 2.16kg The melt index is 0.5-100g / 10min, and the molecular weight distribution index is 4-10;

[0024] Mode (2): The monomer mixture of 1-butene, ethylene and higher α-olefins is carried out in different reactors for olefin polymerization in the presence of Ziegler-Natta catalyst system, and after the olefin polymerization is completed, each reaction The reaction products in the reactor are mixed; the corresponding monomer mixtures in different reactors each ...

Embodiment 1

[0054] The polymerization reaction is carried out by bulk polymerization method, and the air and trace water in the polymerization reactor are removed in advance at 75°C. Add 10mgMgCl to a 5L high-pressure stainless steel polymerization reactor 2 / TiCl 4 Loaded Ziegler-Natta catalyst, 4ml concentration of 1mol / L triethylaluminum and 3ml concentration of 0.2mol / L cyclohexylmethyldimethoxysilane, feed partial pressure of 0.1MPa of hydrogen, a small amount of The liquid phase 1-butene is added to the reactor, and then the monomers 1-butene, 1-hexene and ethylene are introduced into the reactor under the mass flow meter, and the monomer molar ratio is 1-butene: ethylene : 1-hexene is 97:1:2. Stirring was carried out at a stirring speed of 500 rpm, and the reaction was carried out at a polymerization temperature of 75° C. for 1 h. After the reaction was completed, the remaining reaction monomers were discharged to terminate the reaction, and the analysis results of the obtained ...

Embodiment 2

[0056] The catalyst used in embodiment 2, polymerization process conditions and auxiliary agent formula are identical with embodiment 1. The difference from Example 1 is that the molar feed ratio of 1-butene, ethylene and 1-hexene is 88:2:10, and the analysis results of the obtained polymer are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com