A large-size silicon carbide single crystal, substrate, preparation method and device used

A silicon carbide single crystal, large-size technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of high cost, high cost, cumbersome preparation process, etc., achieve less defect density, and produce wafers High rate and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] As a method for preparing a silicon carbide single crystal from any of the above-mentioned crucibles and seed crystal columns, the method comprises the following steps:

[0096] 1) Provide crucible and silicon carbide seed column;

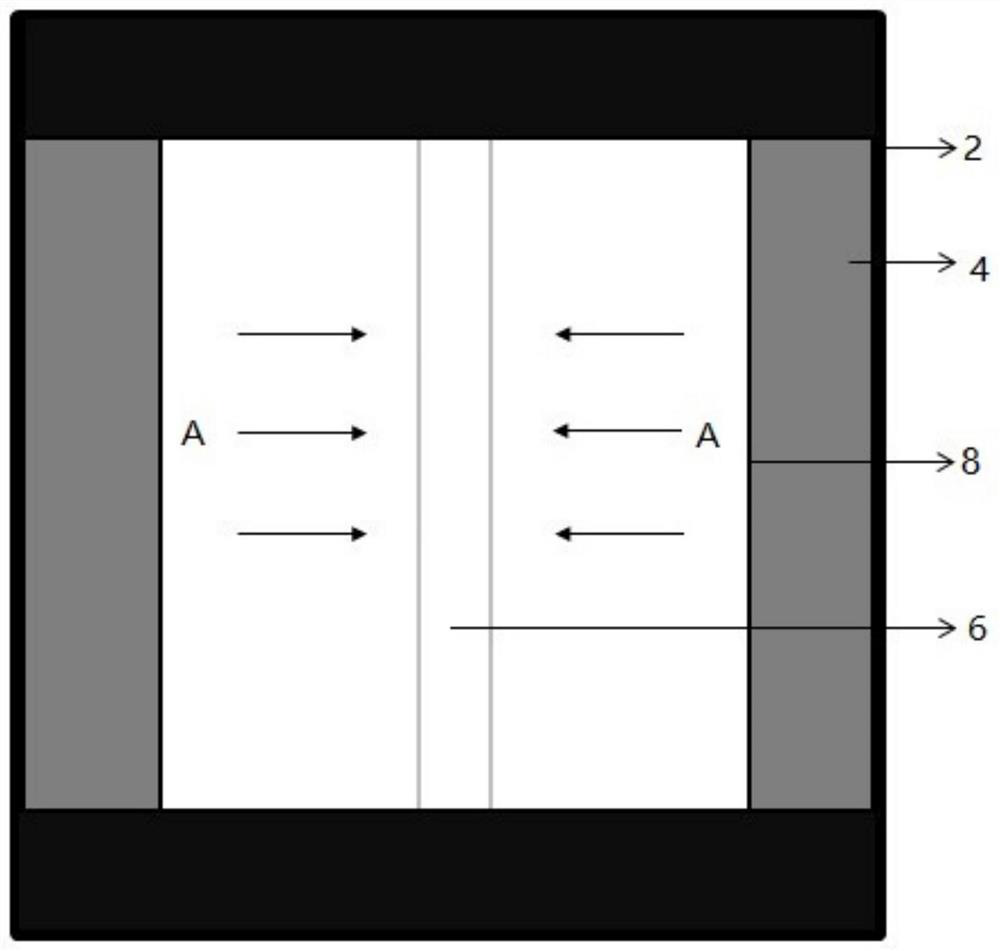

[0097] 2) Put the silicon carbide powder into the raw material cavity formed by the interlayer on the side wall of the crucible, install the silicon carbide seed crystal column in the crucible, and put it into the crystal growth furnace after assembly;

[0098] 3) Increase the temperature of the crystal growth furnace to 2000-2300°C, so that the sublimation gas after the sublimation of the raw materials passes through the inner wall of the interlayer and is transported to the surface of the seed crystal column in the gas phase in the radial direction, and the temperature difference between the inner surface of the inner wall and the surface of the seed crystal T is 50-300°C, and crystal growth is carried out to obtain a silicon carbide singl...

Embodiment 2

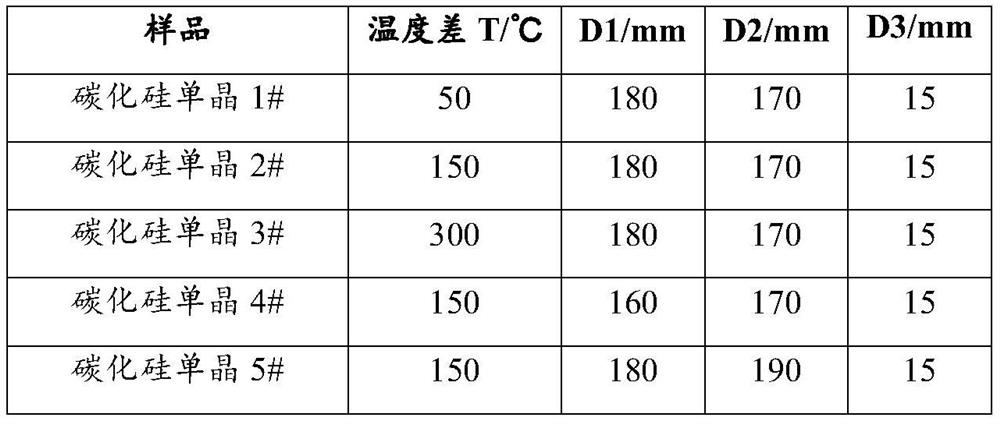

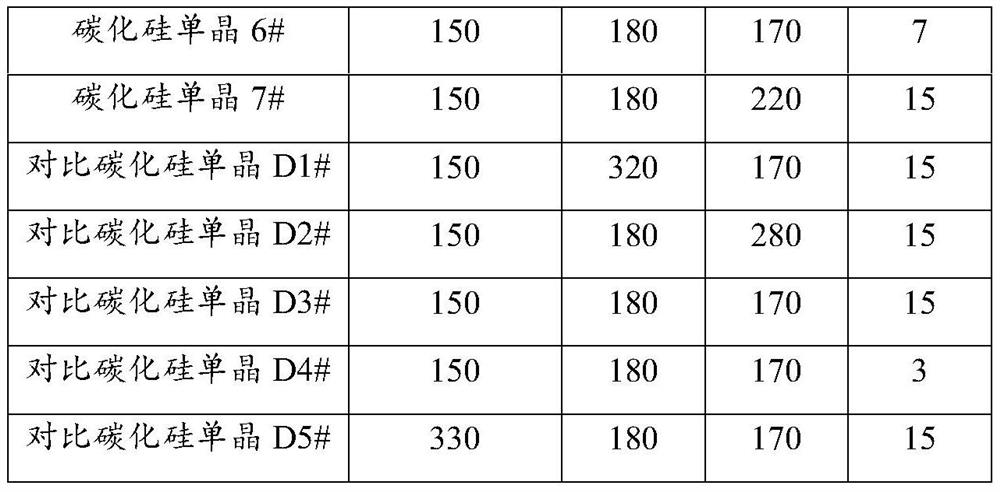

[0101] Taking the preparation of the seed crystal column with a length of 150mm as an example to illustrate the preparation method, according to the method of Example 1, silicon carbide single crystals 1#-7#, and comparative silicon carbide single crystals D1#-D5#, are different from the method of the embodiment The point is in Table 1.

[0102] Table 1

[0103]

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com