After-finishing technology for home textile fabric based on shea butter

A shea butter and finishing technology, applied in fiber processing, textile and papermaking, biochemical fiber processing, etc., can solve the problems of single function, can not effectively meet the needs of consumers, and achieve the effect of improving gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

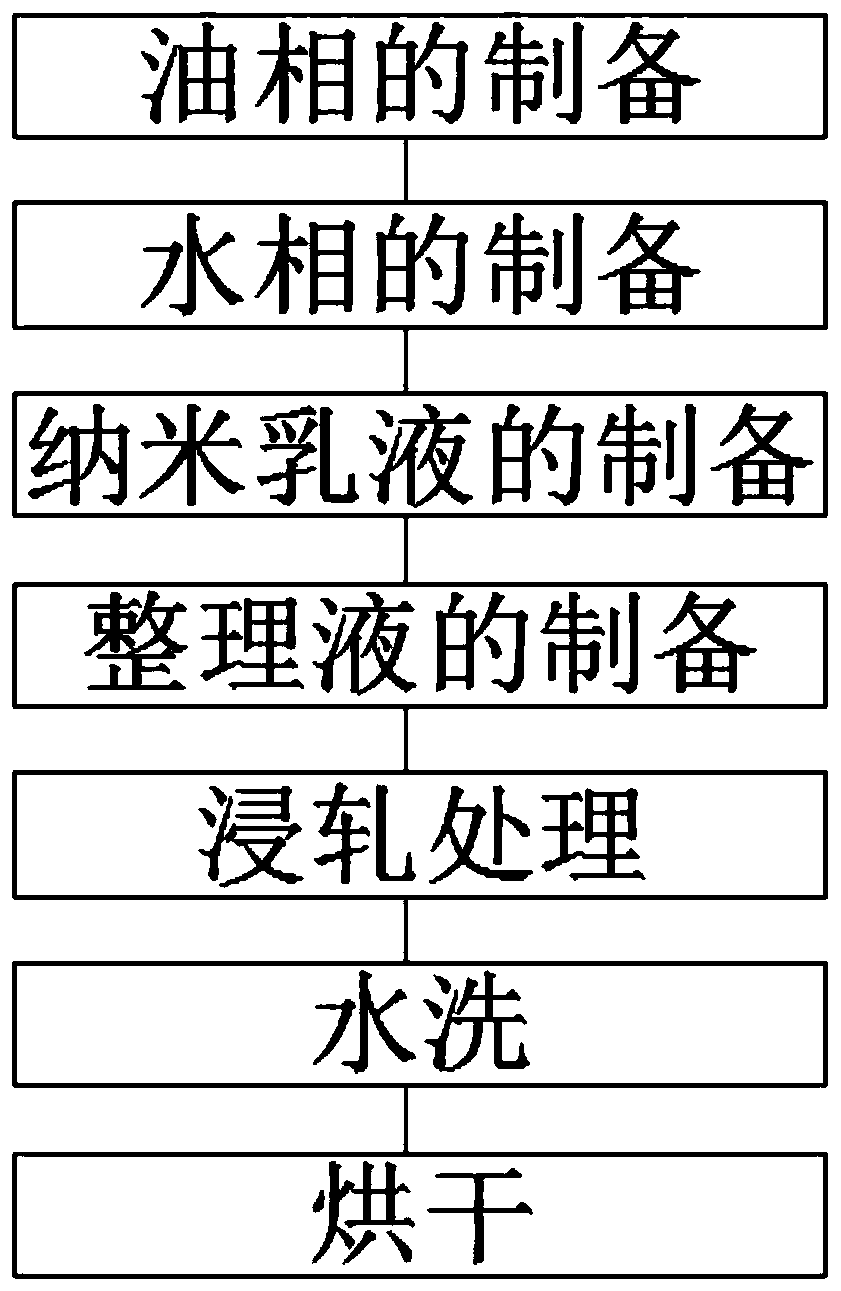

[0023] A post-finishing process for home textile fabrics based on shea butter. After preparation of oil phase, preparation of water phase, preparation of nanoemulsion, preparation of finishing solution, padding treatment, washing and drying steps, the shea butter-based finishing process is completed. Finishing process of home textile fabrics with fruit oil; the specific steps are as follows:

[0024] (1) Preparation of the oil phase: by mass, 12 parts of shea butter, 1 part of unsaturated fatty acid and 0.5 part of emulsifier were mixed uniformly at 60°C to obtain an oil phase; the unsaturated fatty acids were oleic acid, linoleic acid A mixture of one or more of acid and linolenic acid; the emulsifier is selected from sucrose ester or soybean lecithin.

[0025] (2) Preparation of the water phase: by mass, 1200 parts of water, 3.5 parts of polyol and 2.5 parts of metal salt were uniformly mixed to obtain a water phase; the polyol was selected from glycerin, propylene glycol or...

Embodiment 2

[0032] A post-finishing process for home textile fabrics based on shea butter. After preparation of oil phase, preparation of water phase, preparation of nanoemulsion, preparation of finishing solution, padding treatment, washing and drying steps, the shea butter-based finishing process is completed. Finishing process of home textile fabrics with fruit oil; the specific steps are as follows:

[0033] (1) Preparation of oil phase: by mass, 22 parts of shea butter, 2 parts of unsaturated fatty acid and 1.5 parts of emulsifier were mixed uniformly at 70°C to obtain an oil phase; the unsaturated fatty acids were oleic acid, linoleic acid A mixture of one or more of acid and linolenic acid; the emulsifier is selected from sucrose ester or soybean lecithin.

[0034] (2) Preparation of the water phase: by mass, 3200 parts of water, 4.5 parts of polyol and 3.5 parts of metal salt were uniformly mixed to obtain a water phase; the polyol was selected from glycerin, propylene glycol or 1...

Embodiment 3

[0041] A post-finishing process for home textile fabrics based on shea butter. After preparation of oil phase, preparation of water phase, preparation of nanoemulsion, preparation of finishing solution, padding treatment, washing and drying steps, the shea butter-based finishing process is completed. Finishing process of home textile fabrics with fruit oil; the specific steps are as follows:

[0042] (1) Preparation of the oil phase: by mass, 13 parts of shea butter, 1 part of unsaturated fatty acid and 0.5 part of emulsifier were mixed uniformly at 62°C to obtain an oil phase; the unsaturated fatty acids were oleic acid, linoleic acid A mixture of one or more of acid and linolenic acid; the emulsifier is selected from sucrose ester or soybean lecithin.

[0043] (2) Preparation of the water phase: by mass, 1600 parts of water, 3.8 parts of polyol and 2.7 parts of metal salt were uniformly mixed to obtain the water phase; the polyol was selected from glycerin, propylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com