Method and device for culturing shrimps by adopting fully-closed circulating water

A circulating aquaculture and fully enclosed technology, applied in the field of aquaculture water treatment, can solve problems such as hindering the healthy development of shrimp aquaculture, frequent occurrence of diseases, and pollution of coastal waters, so as to benefit from modular replication, save land space, and reduce the cost of aquaculture. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

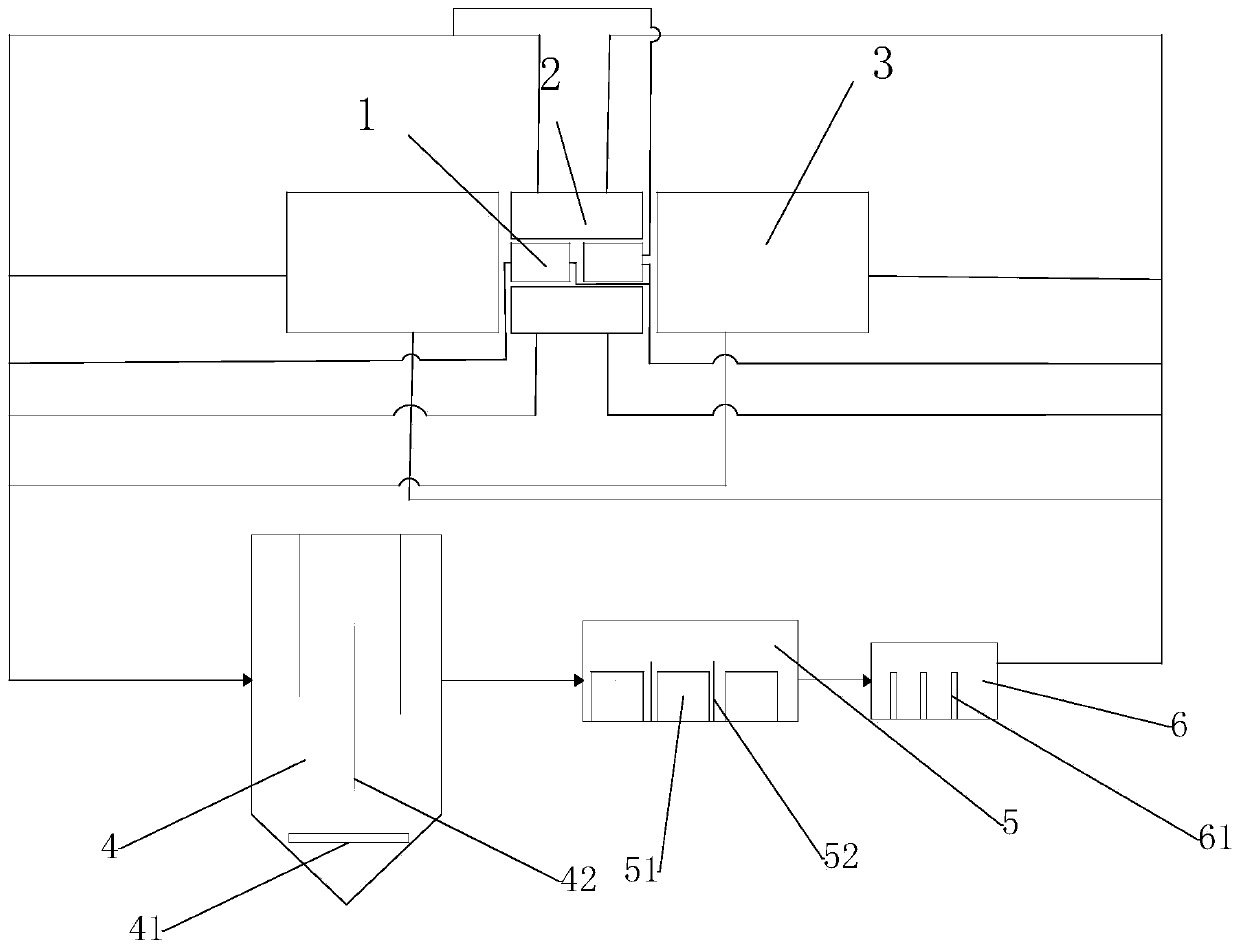

Image

Examples

Embodiment 1

[0038] The density of shrimp fry in primary culture is 10,000 fish / m 3 , the culture time is 20 days; the weight of the shrimp in the first-level culture reaches 0.02-0.05 g / tail, and the shrimp is transferred to the pond;

[0039] The density of shrimp fry in secondary culture is 3000 fish / m 3 , the culture time is 22 days; the weight of the shrimp in the secondary culture reaches 1.8-2.5 grams per tail, and the shrimp is transferred to the pond;

[0040] The density of shrimp fry in the tertiary culture is 450 tails / m 3 , the breeding time is 27 days;

[0041] The type of microalgae includes Thalassiosira and / or Navicula; the initial dosage of microalgae cells in the primary culture is 500-1000 / mL;

[0042] In the three-level breeding system, each level includes four breeding ponds. The water volume in the first-level breeding pond is 80 tons, the water volume in the second-level breeding pond is 300 tons, and the water volume in the third-level breeding pond is 1920 tons...

Embodiment 2

[0050] The multi-level breeding system adopts a three-level breeding system.

[0051] The density of shrimp fry in primary culture is 6000 fish / m 3 , the culture time is 20 days; the weight of the shrimp in the first-level culture reaches 0.02-0.05 g / tail, and the shrimp is transferred to the pond;

[0052] The density of shrimp fry in secondary culture is 1500 fish / m 3 , the culture time is 20 days; the weight of the shrimp in the secondary culture reaches 1.8-2.5 grams per tail, and the shrimp is transferred to the pond;

[0053] The density of shrimp fry in the tertiary culture is 500 tails / m 3 , the breeding time is 30 days;

[0054] The species of microalgae includes Thalassiosira and / or Navicula; the initial dosage of microalgae cells in the primary culture is 800 / mL;

[0055] In the three-level culture system, each level includes four culture ponds, the water volume in the first-level culture pool is 200 tons, the water volume in the second-level culture pool is 800...

Embodiment 3

[0063] The density of shrimp fry in primary culture is 8000 fish / m 3 , the culture time is 20 days; the weight of the shrimp in the first-level culture reaches 0.02-0.05 g / tail, and the shrimp is transferred to the pond;

[0064] The density of shrimp fry in secondary culture is 1300 fish / m 3 , the culture time is 20 days; the weight of the shrimp in the secondary culture reaches 1.8-2.5 grams per tail, and the shrimp is transferred to the pond;

[0065] The density of shrimp fry in the tertiary culture is 440 fish / m 3 , the breeding time is 25 days;

[0066] The species of microalgae include Thalassiosira and / or Navicula; the initial dosage of microalgae cells in the primary culture is 60,000-80,000 / mL.

[0067] In the three-level breeding system, each level includes 6 breeding ponds. The water volume in the first-level breeding pond is 180 tons, the water volume in the second-level breeding pond is 980 tons, and the water volume in the third-level breeding pond is 3240 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com