Light curing 3D printing preparing method for complex double-wall silicon-based ceramic core

A ceramic core and 3D printing technology, which is applied in the field of precision casting, can solve problems such as complex procedures and high costs, and achieve the effects of simplifying the process flow, reducing cost loss, and reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

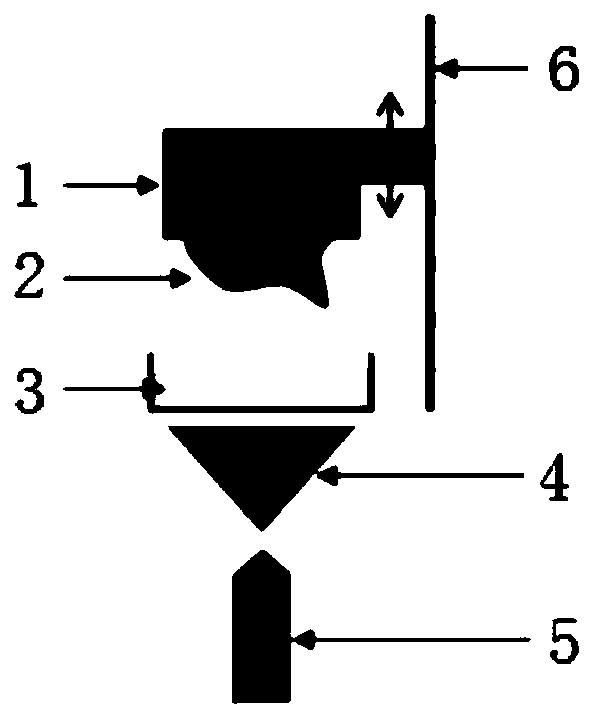

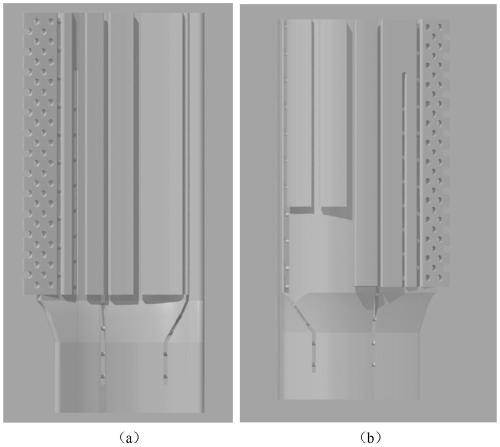

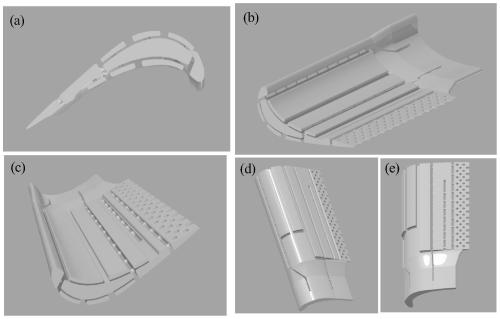

[0064] In this embodiment, the preparation method of single crystal double-walled hollow turbine blade based on light curing technology is as follows:

[0065] (1) Weigh 100g (v=46mL, ρ=2g / cm 3 ); monomer: 20g (18mL) of 1,6-hexanediol diacrylate, 10g (11mL) of diglycidyl hexahydrophthalate; dispersant: 4g (3.5mL) of dipentaerythritol hexaacrylate (DPHA) ), and mixed with sodium polyacrylate 0.8g, ammonium polyacrylate 0.2g, oleic acid 0.2g; photoinitiator: benzoin dimethyl ether 0.8g, 2,4,6-trimethylbenzoyl diphenylphosphine oxide 0.12 g, 0.12g of diarylsulfonium salt, 0.12g of triarylsulfonium salt; light absorber: 0.21g of 2,4-dihydroxybenzophenone, 2-(2′-hydroxyl-5′-methylbenzene base) 0.15g of benzotriazole; mineralizer: 8g of alumina, 6g of zirconia, the particle size of alumina is 20nm-40nm, and the particle size of zirconia is 20-40nm.

[0066] (2) Mix the spherical silicon-based ceramic powder mixed with micron-scale and nano-scale with mineralizer, and process it th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com