Composite calcium-based lubricating grease and preparation method thereof

A complex calcium-based grease, a complex calcium-based technology, applied in the field of grease, can solve the problems of hardening of complex calcium-based grease, poor comprehensive performance of calcium-based polyurea grease, limited promotion and application, etc., so as to improve PB value, improve the hardening problem, the effect of excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

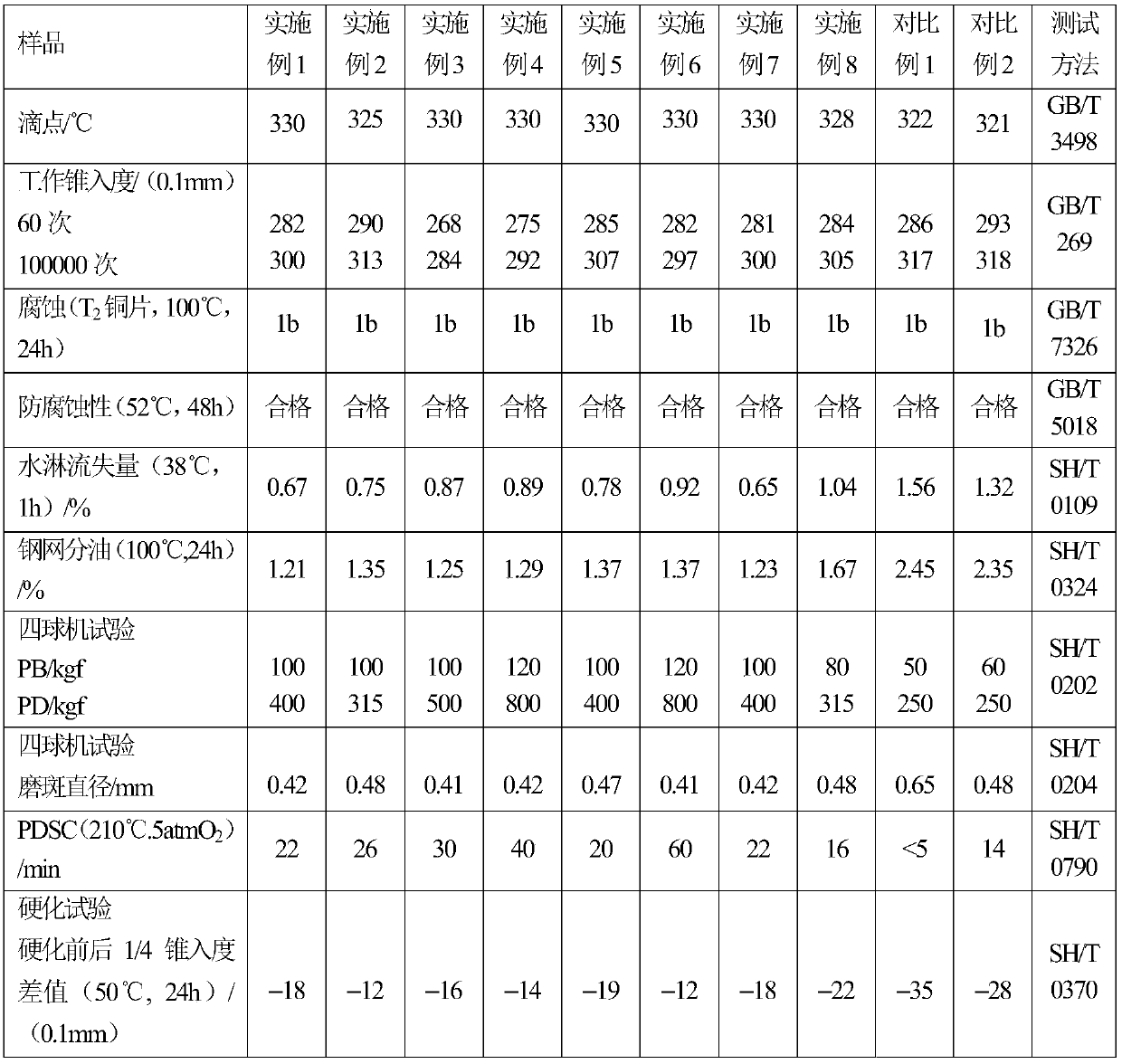

Examples

preparation example Construction

[0025] According to the present invention, the ZrO(OH) 2 Hydrates of are commercially available and can also be prepared. Preferably, in order to further improve the overall performance of the complex calcium-based grease, the ZrO(OH) 2 The hydrate is wet zirconium hydroxide, and the preparation method includes: ZrOX 2 ·nH 2 O and / or ZrO(NO 3 ) 2 ·nH 2 O and / or ZrOSO 4 ·nH 2 O reacts with base contact, X is F, Cl, Br or I.

[0026] According to the present invention, the ZrOX 2 ·nH 2 O and / or ZrO(NO 3 ) 2 ·nH 2 O and / or ZrOSO 4 ·nH 2 The conditions of the contact reaction between O and alkali generally include the temperature of the contact reaction and the time of the contact reaction. The temperature of the contact reaction can be 10-100° C., preferably 40-80° C., and the time of the contact reaction can be appropriately selected according to the temperature of the contact reaction. Generally, it can be 0.5-3h, preferably 1-2h.

[0027] According to the prese...

Embodiment approach

[0032] According to a specific embodiment of the present invention, ZrO(NO 3 ) 2 ·nH 2 In O, n=2.

[0033] According to a specific embodiment of the present invention, ZrOSO 4 ·nH 2 In O, n=1.

[0034] According to the present invention, ZrOX 2 ·nH 2 O and / or ZrO(NO 3 ) 2 ·nH 2 O and / or ZrOSO 4 ·nH 2 The molar ratio of the total amount of O to alkali is generally stoichiometric ratio, but, in order to react more fully, the molar number of alkali can be excessive such as 1-5%, therefore, under the preferred situation, ZrOX 2 ·nH 2 O, ZrO(NO 3 ) 2 ·nH 2 O and ZrOSO 4 ·nH 2 The total amount of O and the OH contained in the base - The molar ratio is 1:2-2.1.

[0035] According to a specific embodiment of the present invention, Zr(NO 3 ) 4 ·nH 2 In O, n=5.

[0036] According to a specific embodiment of the present invention, Zr(SO 4 ) 2 ·nH 2 In O, n=4.

[0037] According to the present invention, Zr(NO 3 ) 4 ·nH 2 O and Zr(SO 4 ) 2 ·nH 2 The mol ra...

specific Embodiment approach

[0066] According to a specific embodiment of the present invention, the alkoxy compound Zr(OR) of zirconium is added 4 The timing of the saponification reaction can also be during the saponification reaction when the saponification reaction begins. -3h, preferably 0.5-2h. Among them, zirconium alkoxide Zr(OR) 4 The molar ratio to water is 1:4-20; preferably, the reaction is carried out under stirring.

[0067] According to a specific embodiment of the present invention, the alkoxy compound Zr(OR) of zirconium is added 4 The timing may be that after the saponification reaction is completed, the reaction temperature with water is 10-140°C, preferably 70-110°C, and the reaction time is 0.2-3h, preferably 0.5-2h. Among them, zirconium alkoxide Zr(OR) 4 The molar ratio to water is 1:4-20; preferably, the reaction is carried out under stirring.

[0068] According to the present invention, the saponification reaction needs to be carried out in the presence of water. The present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com