Continuous wort oxygenating method and oxygenating device thereof

A technology of wort and venturi tube, which is applied in the field of wort continuous oxygenation method and oxygenation device, can solve the problems of uneven wort oxygenation method and lower higher alcohol content, and achieve easy control and implementation, flexibility Strong, drinkability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention relates to a method for continuous oxygenation of wort. A wort oxygenation device is used to oxygenate the wort, and after the oxygenation, the wort is fermented in a fermenter. According to production requirements, 5 pots of wort were put into the fermenter. Yeast was added to the first pot when it was cooling, and yeast was not added to the remaining 4 pots. Each pot of wort needed constant oxygenation before feeding. In this example, Set the wort flow rate to 100m 3 / h, the compressed air flow rate is 4.0m 3 / h.

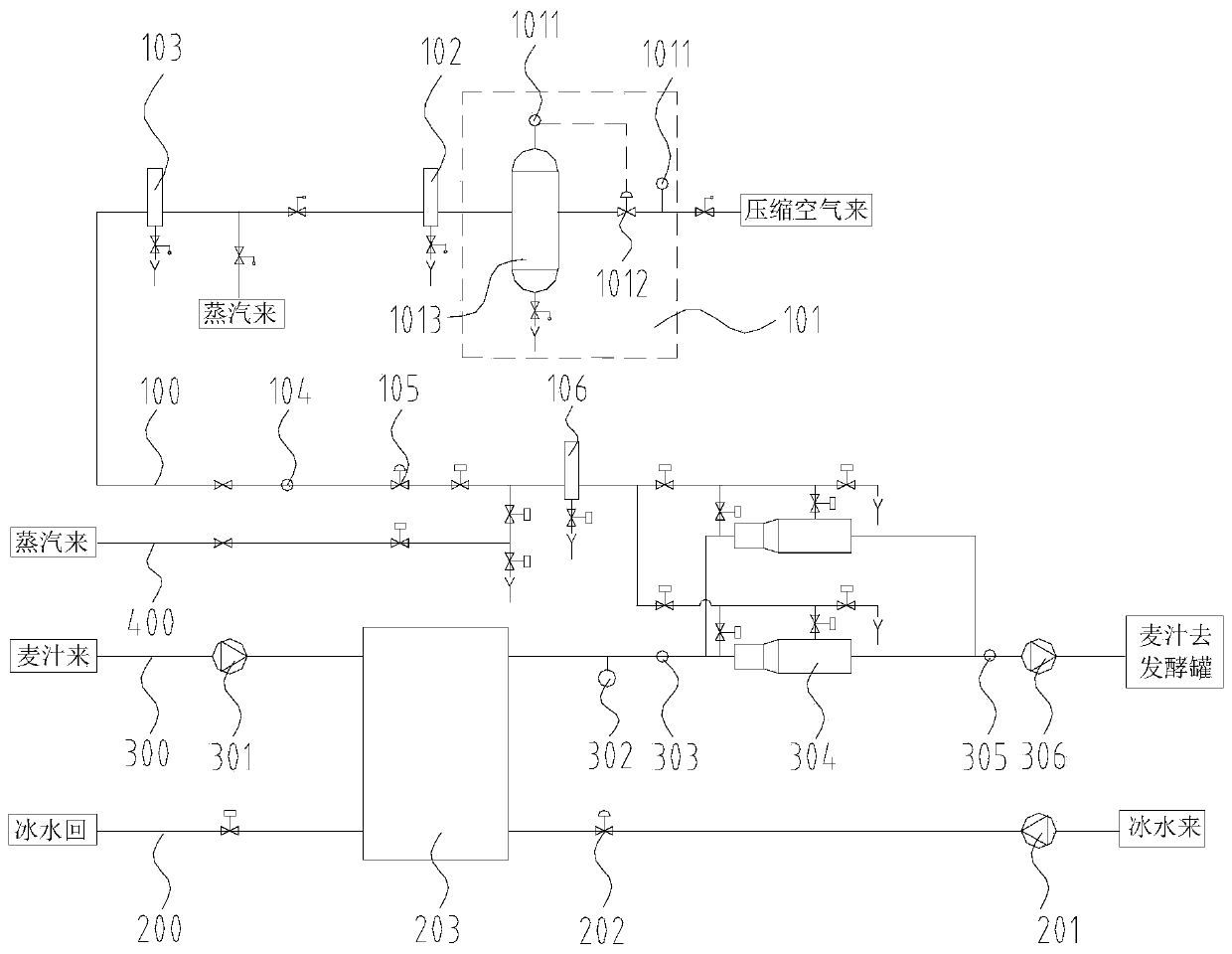

[0037] The wort continuous oxygenation device includes a compressed air system, a cooling system, a wort system, a steam system and a control system.

[0038]The compressed air system includes a pressure stabilizing device 101 , a compressed air flow meter 104 and a compressed air regulating valve 105 connected in sequence through a compressed air pipeline 100 . The voltage stabilizing device 101 includes a pressure probe 1011, a regulating...

experiment example 1

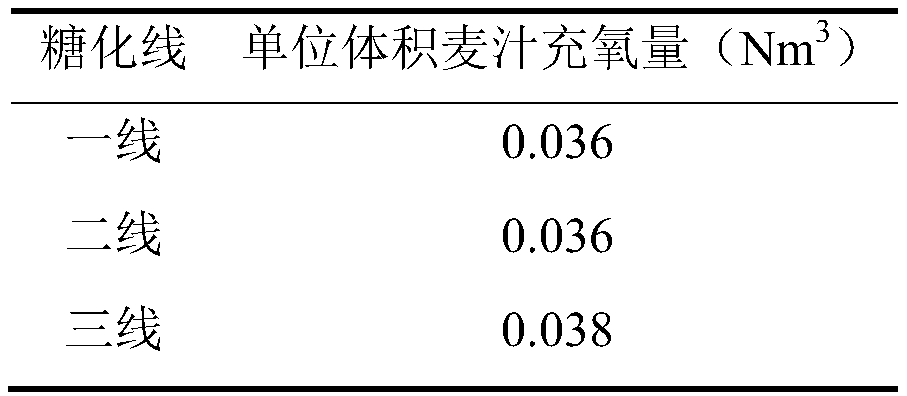

[0052] Adopt the method of embodiment 1 to carry out oxygenation to three saccharification lines, detect the amount of oxygenation per unit volume of wort, the result is as shown in table 1:

[0053] Table 1. Oxygenation of wort per unit volume in different saccharification lines

[0054]

[0055] As can be seen from Table 1, the oxygenation amount per unit wort volume of the three saccharification lines is basically the same, indicating that the oxygenation method of the present invention is constant in oxygenation.

experiment example 2

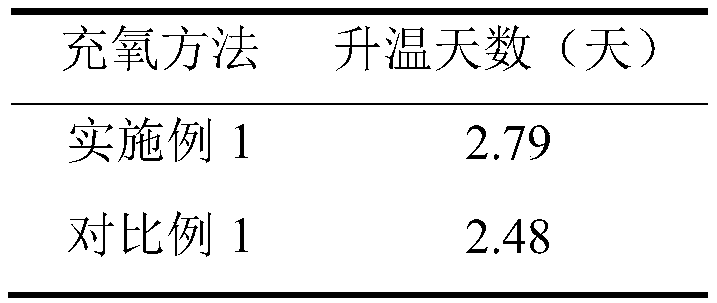

[0057] The heating days of wort fermentation in each of the 50 fermenters were counted, and the average heating days were calculated. The results are shown in Table 2:

[0058] Table 2. Fermentation heating days

[0059]

[0060] The number of days of heating up can indirectly characterize the rate of sugar reduction in the fermentation process. The rate of sugar reduction is mainly affected by the amount of yeast added, the activity of yeast, and the amount of oxygenation. influences. As can be seen from Table 3, the heating days of Example 1 are slightly higher than that of Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com