A method for preventing nodulation of carbon sleeve rolls of continuous annealing furnace

The technology of continuous annealing furnace and carbon sleeve roll is applied in the field of steel rolling technology, which can solve the problems of inability to prevent carbon sleeve roll nodules and influence on production efficiency, and achieve the effects of improving production safety, prolonging service life and improving surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

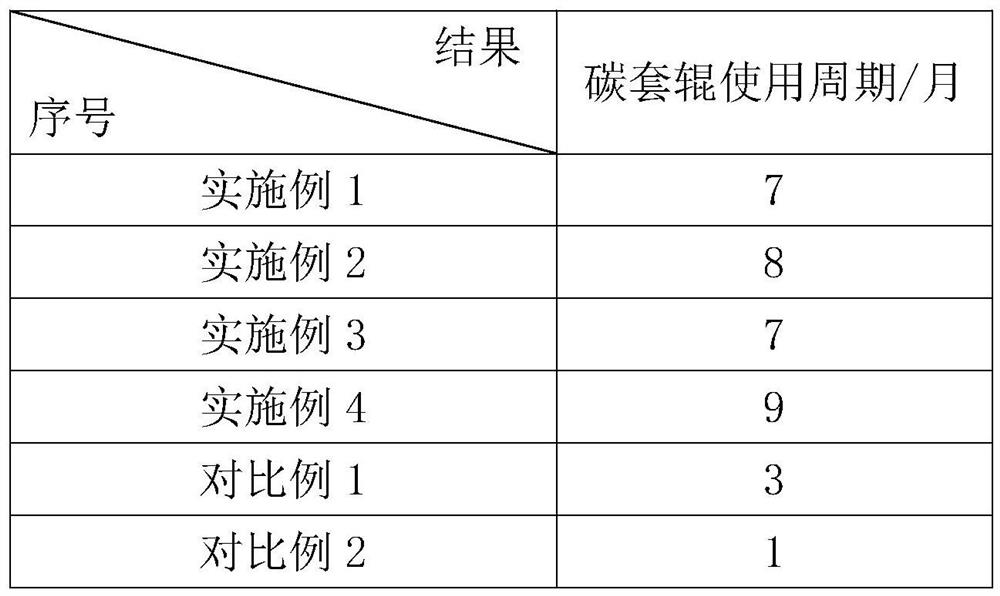

Examples

Embodiment 1

[0023] Normal alkali cleaning, electrolytic cleaning, rinsing and drying are performed on non-oriented silicon steel. After cleaning, wipe the surface of the non-oriented silicon steel with filter paper for 3 seconds, and the surface of the filter paper is free of oil;

[0024] After the non-oriented silicon steel is cleaned, the surface is passivated by a sodium chromate solution with a pH value of 4-6, and then rinsed and dried. The pH value is 4-6. The sodium chromate concentration in the sodium chromate solution is 20g / L, the pH value is 5, and the solution temperature is 45°C;

[0025] After the non-oriented silicon steel is passivated, it is continuously annealed and heated in the open flame heating section. The furnace temperature in the open flame section is 1050 ° C. The open fire section adopts a mixed combustion method of coke oven gas and compressed air;

[0026] The non-oriented silicon steel is kept in the soaking section, the furnace temperature in the soaking ...

Embodiment 2

[0030] Normal alkali cleaning, electrolytic cleaning, rinsing and drying are performed on non-oriented silicon steel. After cleaning, wipe the surface of the non-oriented silicon steel with filter paper for 3 seconds, and the surface of the filter paper is free of oil;

[0031] After the non-oriented silicon steel is cleaned, the surface is passivated by a sodium chromate solution with a pH value of 4-6, and then rinsed and dried. The pH value is 4-6. The sodium chromate concentration in the sodium chromate solution is 30g / L, the pH value is 5, and the solution temperature is 45°C;

[0032] After the non-oriented silicon steel is passivated, it is continuously annealed and heated in the open flame section. The furnace temperature in the open flame section is 1100 ° C. The open fire section adopts a mixed combustion method of coke oven gas and compressed air;

[0033] After the non-oriented silicon steel is heated in the open flame section, it enters the soaking section for he...

Embodiment 3

[0037] Normal alkali cleaning, electrolytic cleaning, rinsing and drying are performed on non-oriented silicon steel. After cleaning, wipe the surface of the non-oriented silicon steel with filter paper for 3 seconds, and the surface of the filter paper is free of oil;

[0038] After the non-oriented silicon steel is cleaned, the surface is passivated by a sodium chromate solution with a pH value of 4-6, and then rinsed and dried. The pH value is 4-6, the sodium chromate concentration in the sodium chromate solution is 30g / L, the pH value is 5, and the solution temperature is 50°C;

[0039] After the non-oriented silicon steel is passivated, it is continuously annealed and heated in the open flame section. The furnace temperature in the open flame section is 1100 ° C. The open fire section adopts a mixed combustion method of coke oven gas and compressed air;

[0040] After the non-oriented silicon steel is heated in the open flame section, it enters the soaking section for he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com