Fireproof material for protective building materials and preparation method thereof

A technology of fireproof materials and building materials, applied in the field of building materials, can solve problems such as poor fireproof effect, threats to property and life safety, etc., and achieve good fireproof performance, good thermal stability, and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

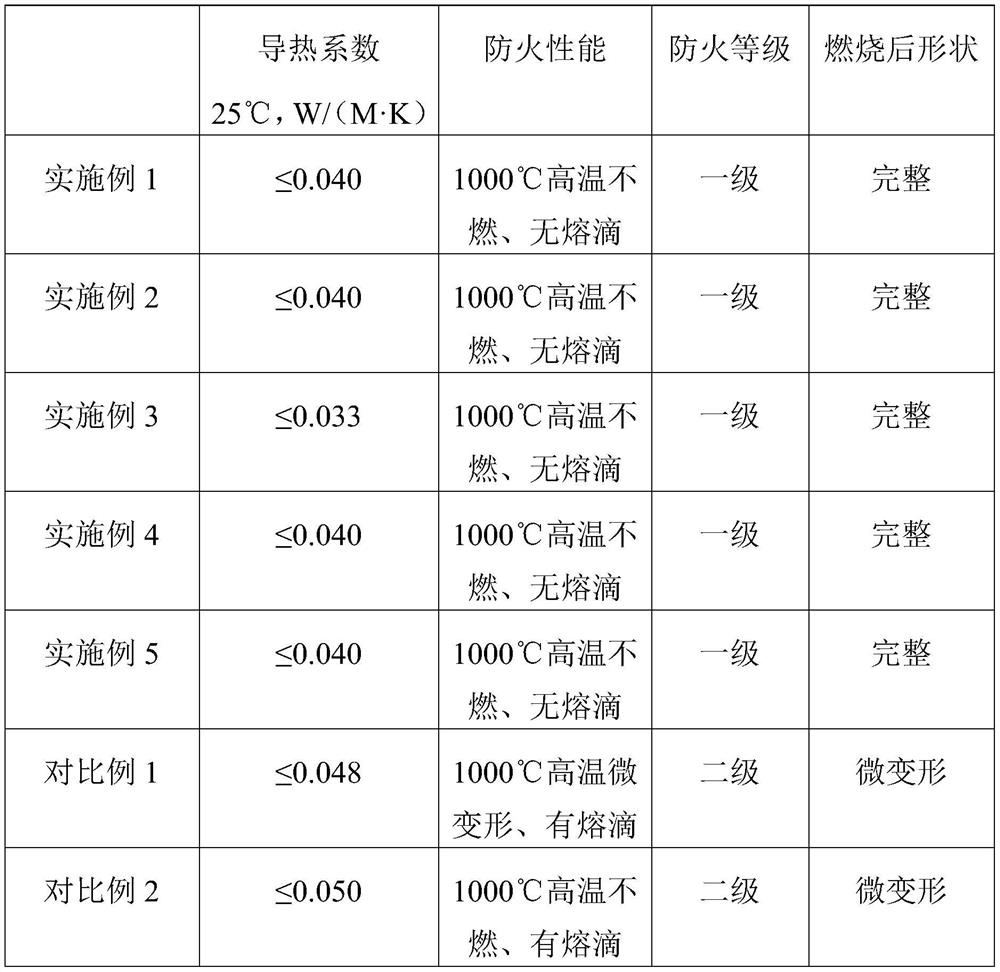

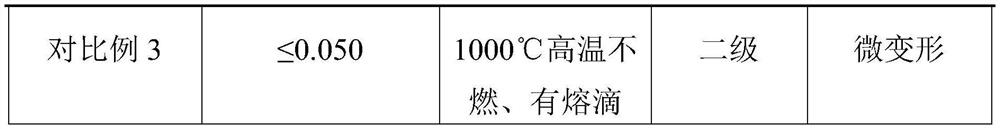

Examples

Embodiment 1

[0020] A fireproof material for protective building materials: comprising the following raw materials in parts by weight: 15 parts of magnesium chloride, 12 parts of magnesium oxide, 10 parts of triethylenetetramine, 7 parts of ethylenediamine, 10 parts of aluminum hydroxide, and 10 parts of modified polystyrene resin part, 15 parts of expandable graphite, 8 parts of hydrotalcite, 20 parts of fire retardant; Said fire retardant is ammonium phosphate, pecan nut shell, borax that the volume ratio is 0.1:1:1.2.

Embodiment 2

[0022] A fireproof material for a protective building material: comprising the following raw materials in parts by weight: 60 parts of magnesium chloride, 55 parts of magnesium oxide, 30 parts of triethylenetetramine, 12 parts of ethylenediamine, 30 parts of aluminum hydroxide, 30 parts of phenolic resin, expandable 55 parts of graphite, 12 parts of hydrotalcite, and 33 parts of flame retardant; the flame retardant is ammonium phosphate, pecan husk, and borax with a volume ratio of 0.3:5:3.

Embodiment 3

[0024] A fireproof material for protective building materials: comprising the following raw materials in parts by weight: 40 parts of magnesium chloride, 35 parts of magnesium oxide, 20 parts of triethylenetetramine, 10 parts of ethylenediamine, 20 parts of aluminum hydroxide, 20 parts of modified polystyrene resin part, 35 parts of expandable graphite, 10 parts of hydrotalcite, 26 parts of fire retardant; Said fire retardant is ammonium phosphate, pecan shell, borax that volume ratio is 0.2:3:2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com