Preparation method of novel graphene aluminum composite material and graphene aluminum composite material

A technology of aluminum composite materials and graphene, which is applied in the field of materials, can solve the problems of graphene being difficult and dispersed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

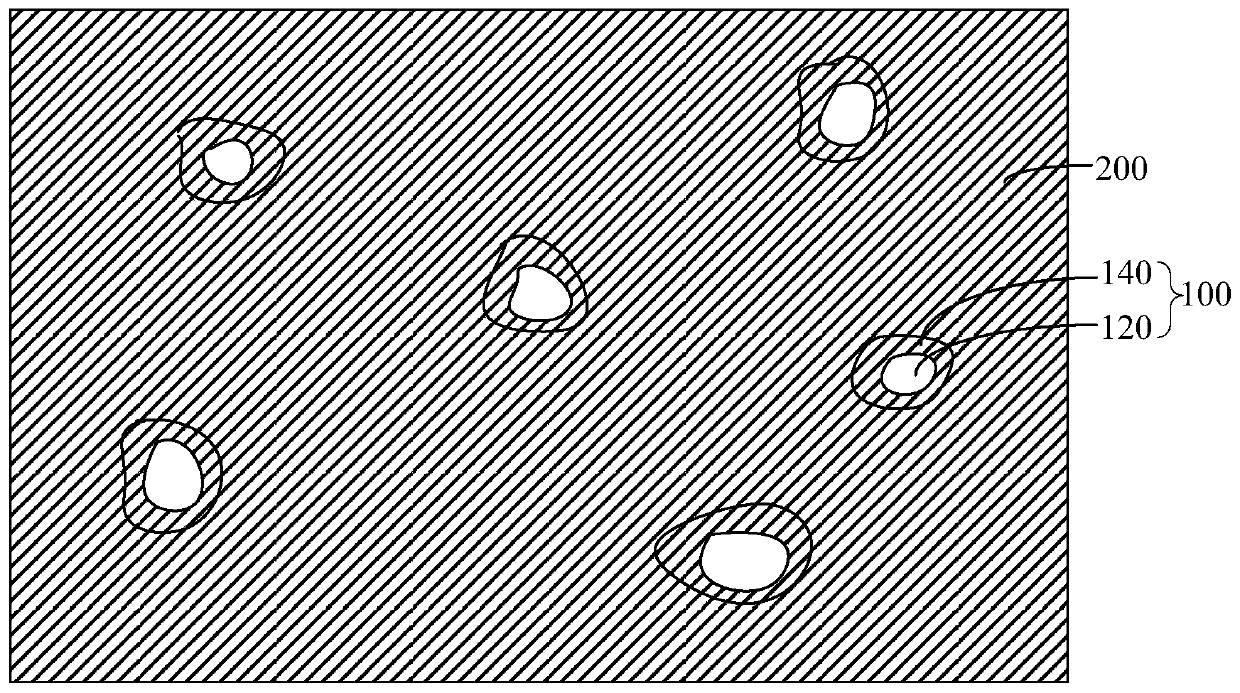

[0028] see figure 1 , the embodiment of the present application provides a preparation method of a novel graphene-aluminum composite material, comprising:

[0029] S100, using a magnetron sputtering method to form an aluminum film 140 on the graphene powder 120 to obtain a modified graphene powder 100;

[0030] S200, adding the modified graphene powder 100 into the molten aluminum liquid 200 and stirring, so that the modified graphene powder 100 is uniformly dispersed in the aluminum liquid 200 to obtain a mixed system; and

[0031] S300, heating and curing the mixed system.

[0032] In the embodiment of the present invention, the modified graphene powder 100 is obtained by first forming an aluminum film 140 on the graphene powder 120, and then the modified graphene powder 100 is mixed with molten aluminum liquid 200 to prepare graphene aluminum composite material. By forming the aluminum film 140 on the surface of the graphene powder 120, it is beneficial to the dispersion...

Embodiment 1

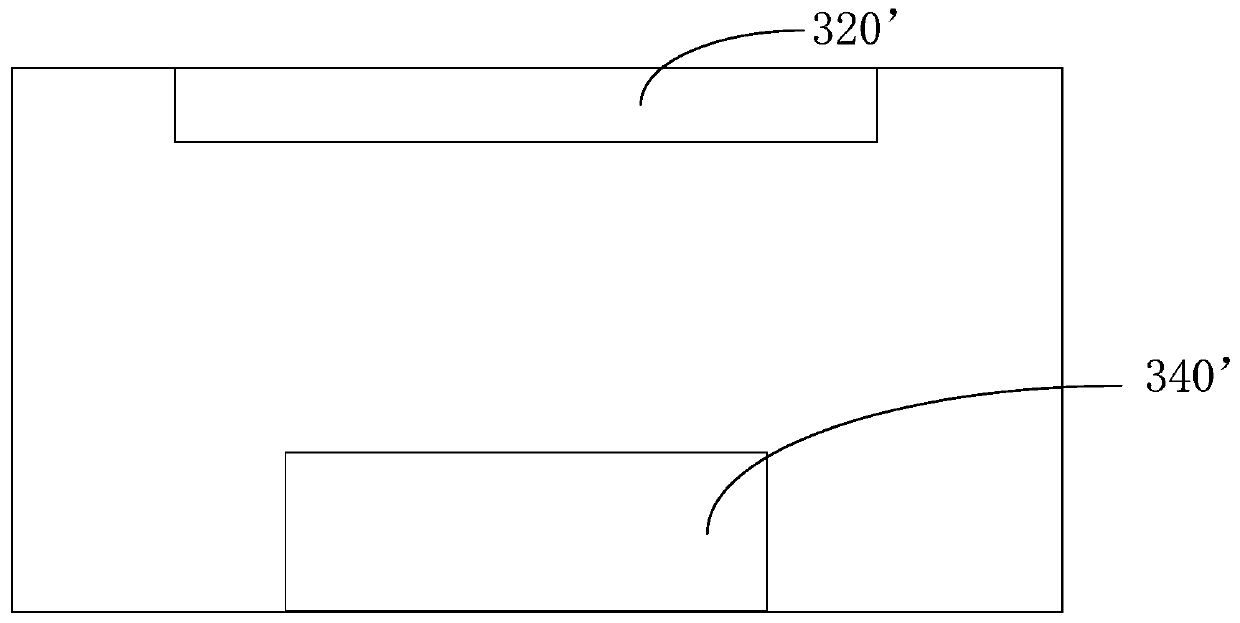

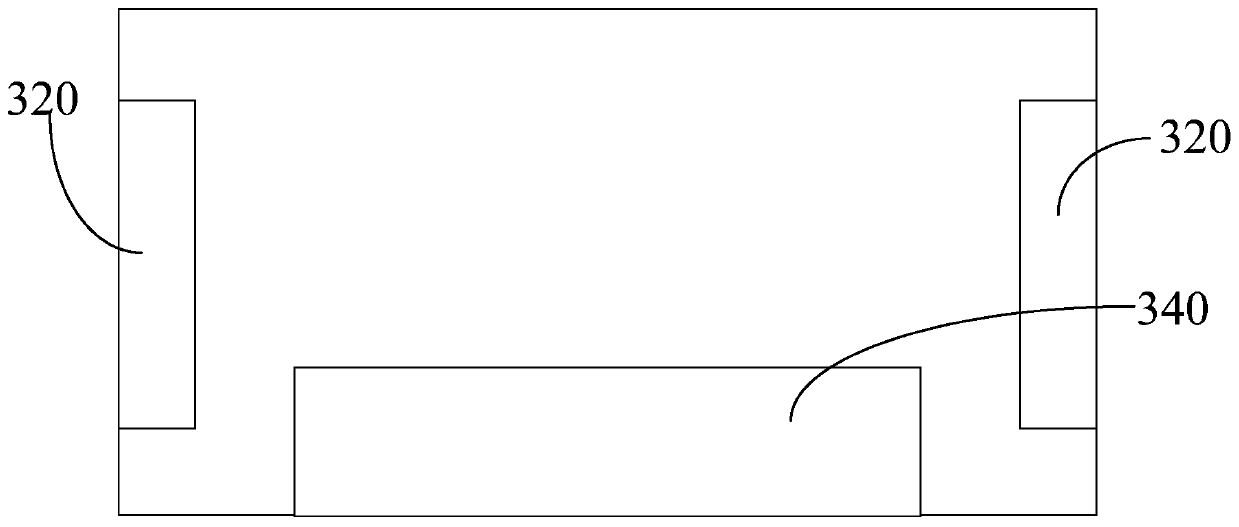

[0050] 1g graphene powder 120 is placed in such as image 3 As shown on the surface of the sample platform 340 of the working chamber of the magnetron sputtering apparatus, the air pressure in the working chamber is evacuated to below 4Pa by vacuuming. The plasma current was modulated to 5mA, and the time was modulated to 2min, and the aluminum sputtering target 320 was arranged horizontally opposite to the two sides of the sample platform 340 . The graphene powder 120 has a sheet diameter of 1 μm and a thickness of 1 nm.

[0051] The modified graphene powder 100 obtained with the aluminum-coated film 140 is collected, and the thickness of the obtained aluminum film 140 of the modified graphene split is about 2 μm.

[0052] After the aluminum material is melted into molten aluminum liquid 200, the obtained modified graphene powder 100 is put into the aluminum liquid 200 in a manner similar to an intermediate alloy, and stirred at 180 rpm for 30 minutes to assist the modificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com