Method for reducing contact resistance of n-type AlGaN-based materials and application thereof

A contact resistance, n-type technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as difficulty in ohmic contact preparation, and achieve the effect of ensuring repeatability and reliability, improving electrical performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for reducing the contact resistance of an n-type AlGaN material, including:

[0040] (1) Epitaxially grow AlN layer, AlN / AlGaN superlattice layer, n-AlGaN layer on the substrate in sequence;

[0041] (2) Etching part of the n-AlGaN layer, the etching depth is 200nm; the etching can be wet etching, dry ICP etching or RIE etching;

[0042] (3) In protective gas N 2 , under the condition of the flow rate of 9000sccm, the NH with the flow ratio of 3:1 3 with N 2 The mixed gas is used as process gas, and the material obtained in step (2) is subjected to high-temperature treatment;

[0043]The temperature of the high temperature treatment is 900°C, the pressure is 100mbar, and the treatment time is 30 minutes; during the high temperature treatment, the rate of heating and cooling is 2°C / sec;

[0044] After the high temperature treatment, cool down to room temperature.

[0045] Effect test:

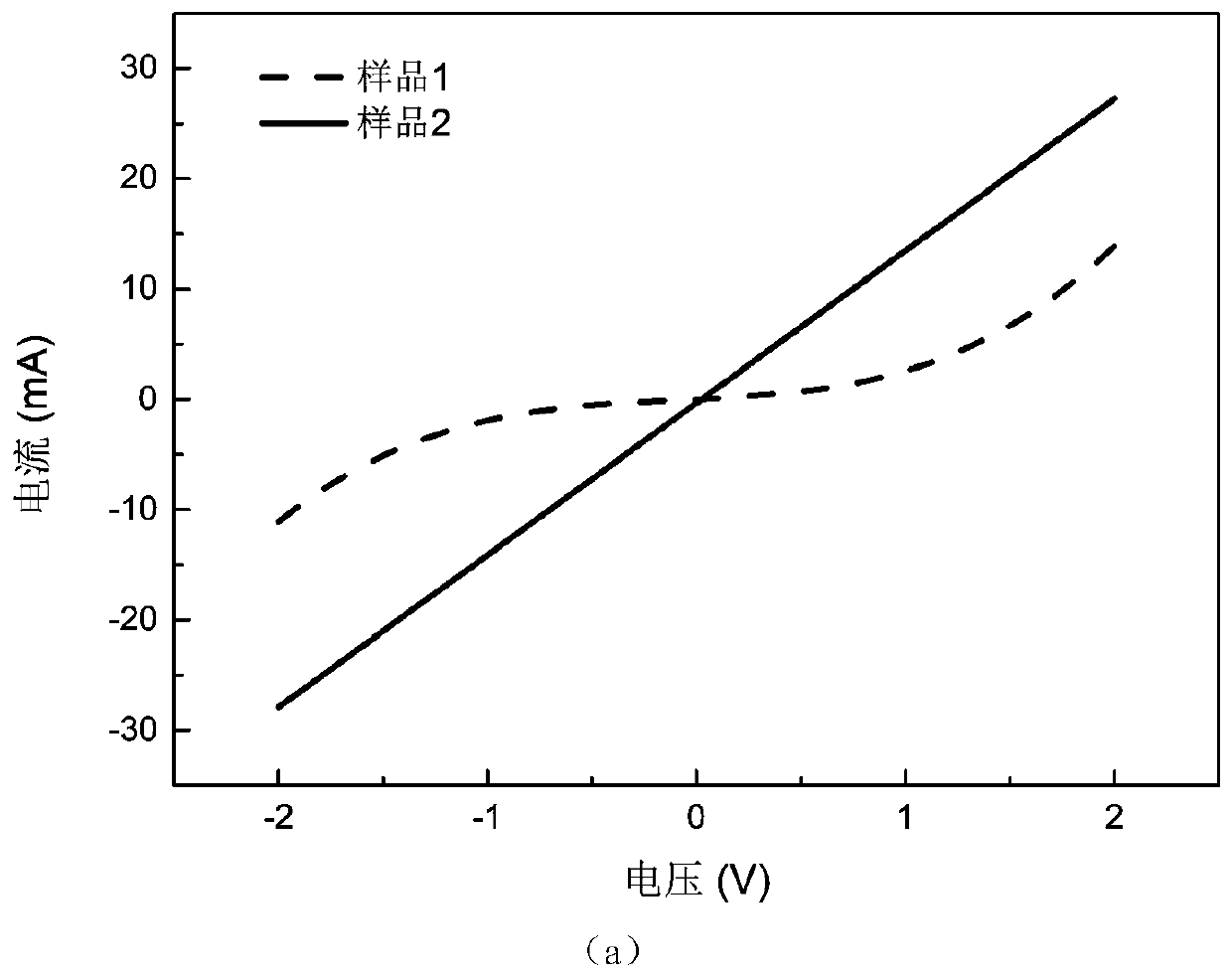

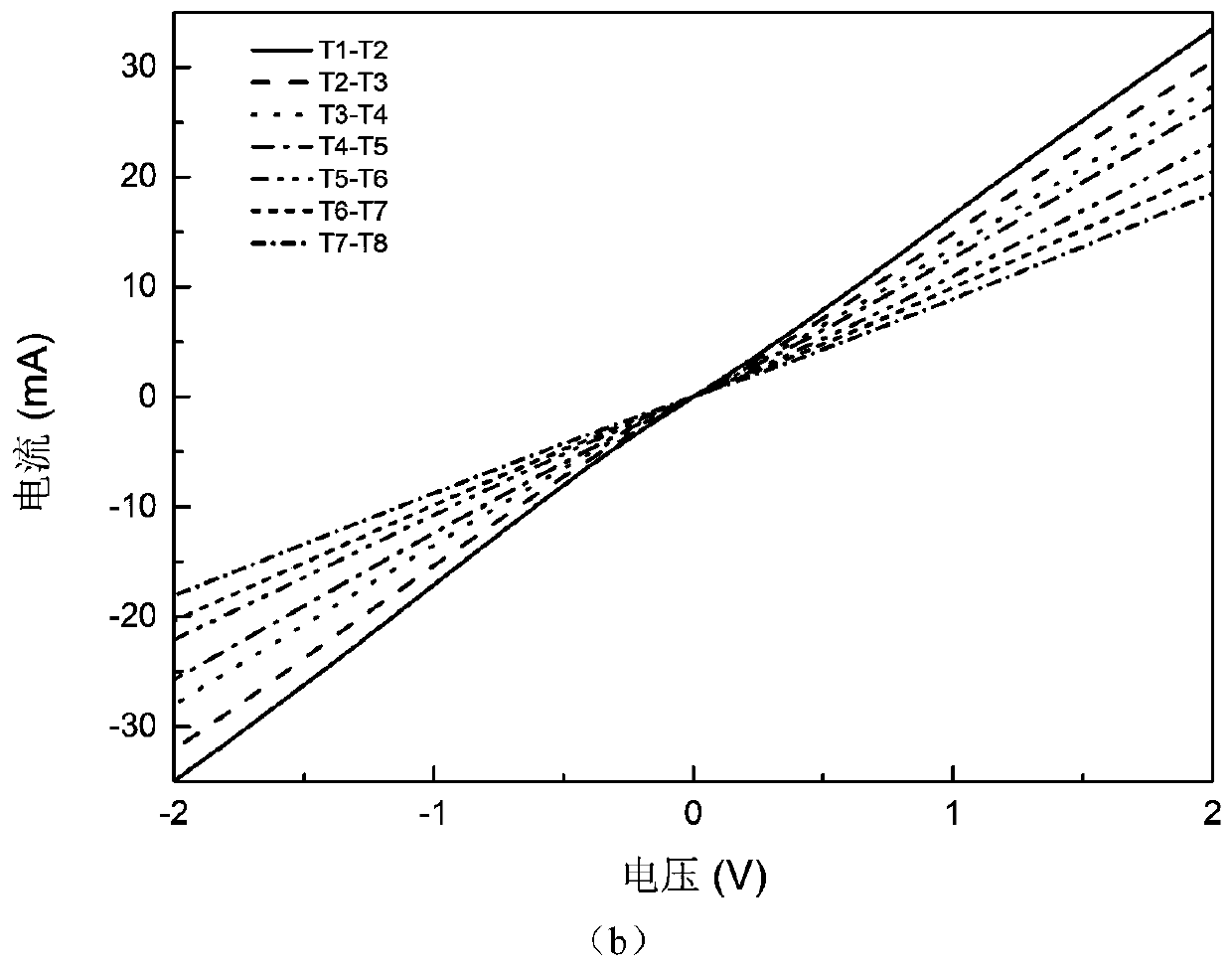

[0046] Sample 1: the n-type AlGaN material ob...

Embodiment 2

[0054] This embodiment provides a method for preparing a deep ultraviolet LED chip, comprising the following steps:

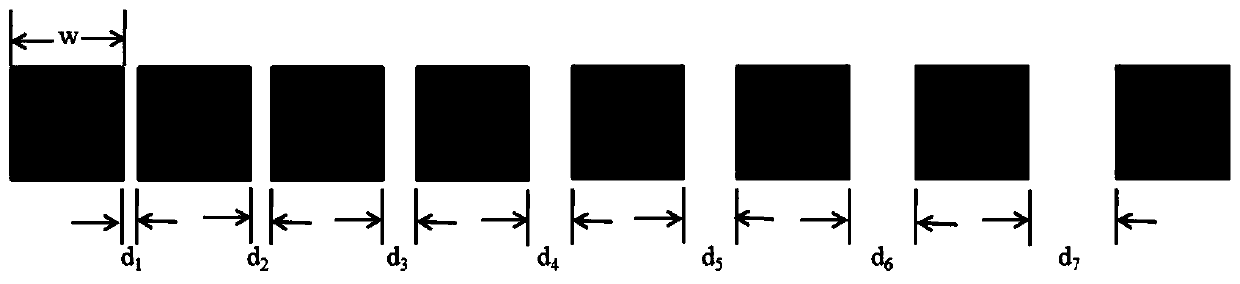

[0055] (1) Epitaxial growth of AlN layer 2, AlN / AlGaN layer 3, n-AlGaN layer 4, multiple quantum well layer 5, p-AlGaN layer 6 and p-GaN layer 7 on the clean sapphire surface 1 in sequence by using MOCVD equipment, and structured as image 3 as shown in (a);

[0056] (2) By photolithography and ICP etching technology, remove the p-GaN layer, p-AlGaN layer, multi-quantum well layer and n-AlGaN layer of partial thickness in some regions, exposing the n-AlGaN layer surface, such as image 3 as shown in (b);

[0057] (3) Through photolithography and ICP etching technology, the deep etching channel of the chip is prepared, extending to the sapphire surface, and the chip is divided into independent units, such as image 3 as shown in (c);

[0058] (4) with N 2 +H 2 / NH 3 It is the process gas, and the material obtained in step (3) is subjected to high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com