Megawatt-level photoconductive semiconductor device and electrode connection and insulation packaging method

A semiconductor, megawatt-level technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components and other directions, can solve problems such as no technical solutions, and achieve the effect of reducing ohmic contact resistance and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

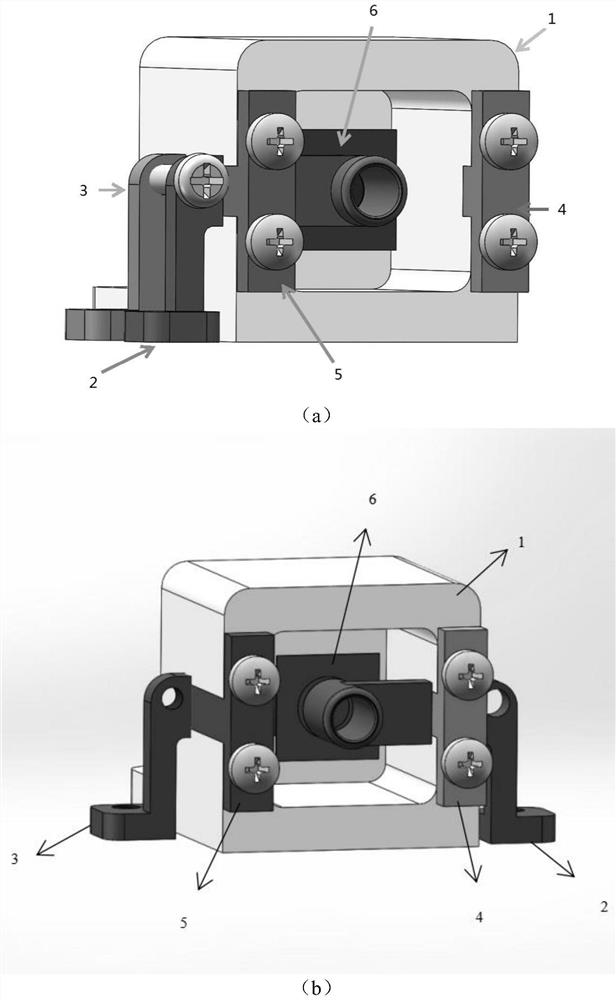

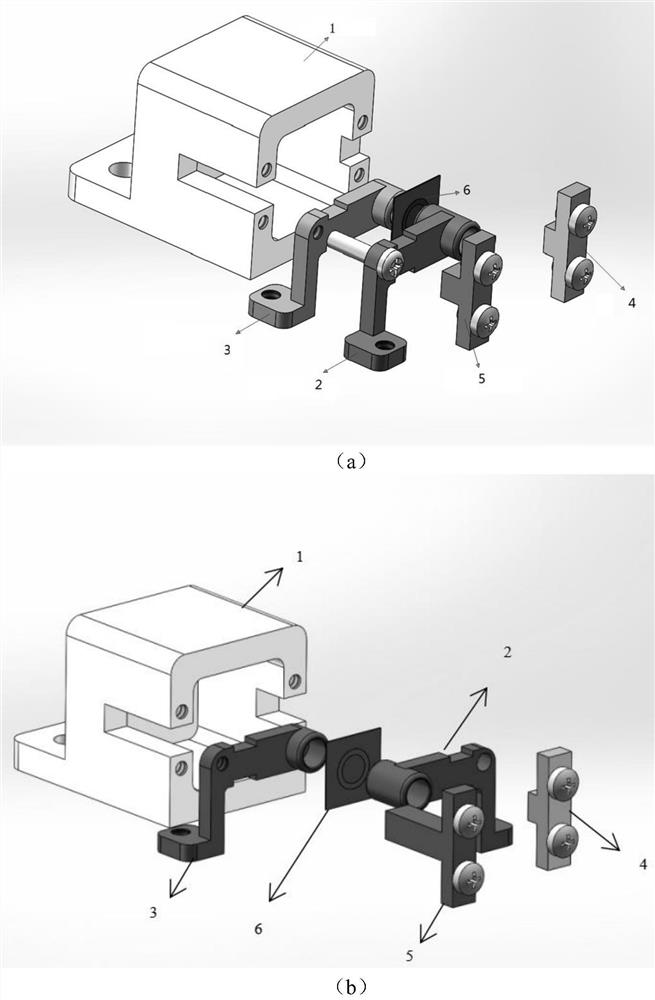

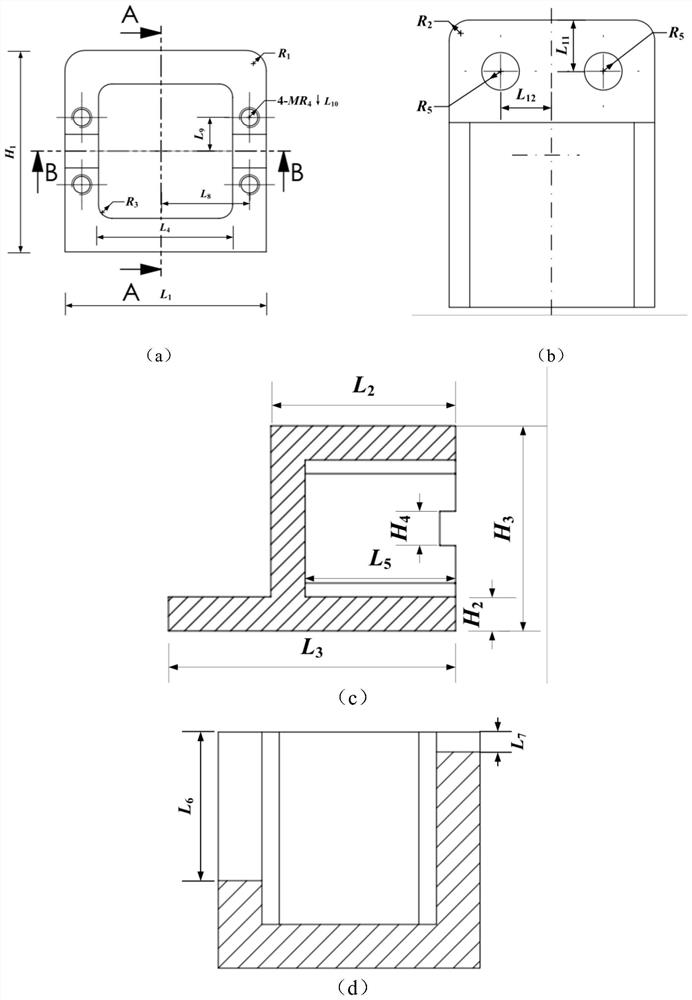

[0030] Such as figure 1 As shown, the present invention consists of an insulating packaging box 1, a positive electrode 2, a negative electrode 3, a first fixing plate 4, a second fixing plate 5, and a SiC wide bandgap photoconductive semiconductor wafer 6 covered with a zinc oxide transparent electrode. Among them, the insulating packaging box 1 is a hollow cube with a deep groove on one side of the cube, and the positive electrode 2 and the negative electrode 3 are stuck in the upper and lower surfaces of the left side of the "factory" through the grooves of the Chinese character "-". In the deep groove, it is pressed and fixed by the second fixed plate 5 with a protrusion in the middle; the positive electrode 2 and the negative electrode 3 are both in the shape of "factory", and a hollow cylinder is arranged at the right end of the "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com