Activation method of electrocatalyst, obtained MoS2 activated electrocatalyst and application

A technology of electrocatalyst and activation method, which can be applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as poor electrochemical hydrogen evolution catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

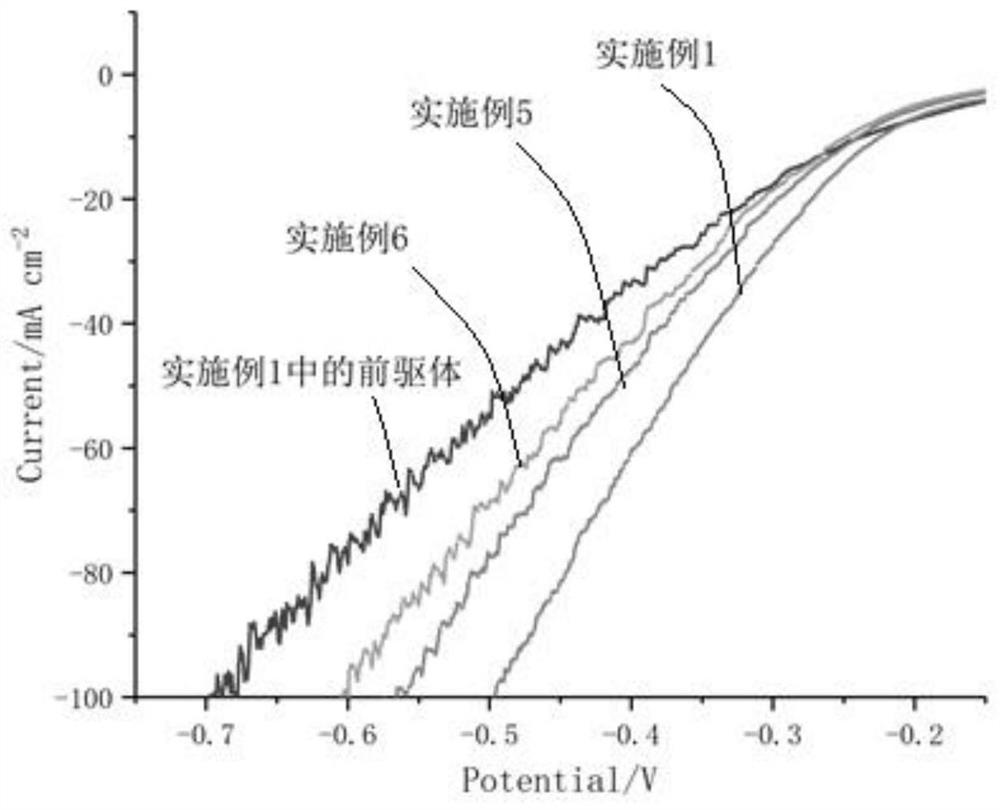

Embodiment 1

[0027] A method for activating an electrocatalyst, specifically comprising the following steps:

[0028] 1) Mix 0.25g of sodium molybdate, 0.35g of thiourea and 18ml of deionized water, then stir for 10min with an electromagnetic stirrer until they are evenly mixed;

[0029] 2) Take a 2cm×2cm carbon cloth and clean it with an ultrasonic cleaner for 10 minutes, wherein the ultrasonic power of the ultrasonic cleaner is set to 150W;

[0030] 3) Pour the uniformly stirred solution in step 1) into a high-pressure reactor lined with polytetrafluoroethylene, and then put the cleaned carbon cloth in step 2) into the above solution;

[0031] 4) Heat the high-pressure reaction kettle to 180°C with an electric blast drying oven and keep it for 24 hours to perform hydrothermal treatment on the solution with carbon cloth in step 3). After the heating is completed, let the reaction kettle cool down naturally to room temperature, then open the reactor, take out the sample, and wash the samp...

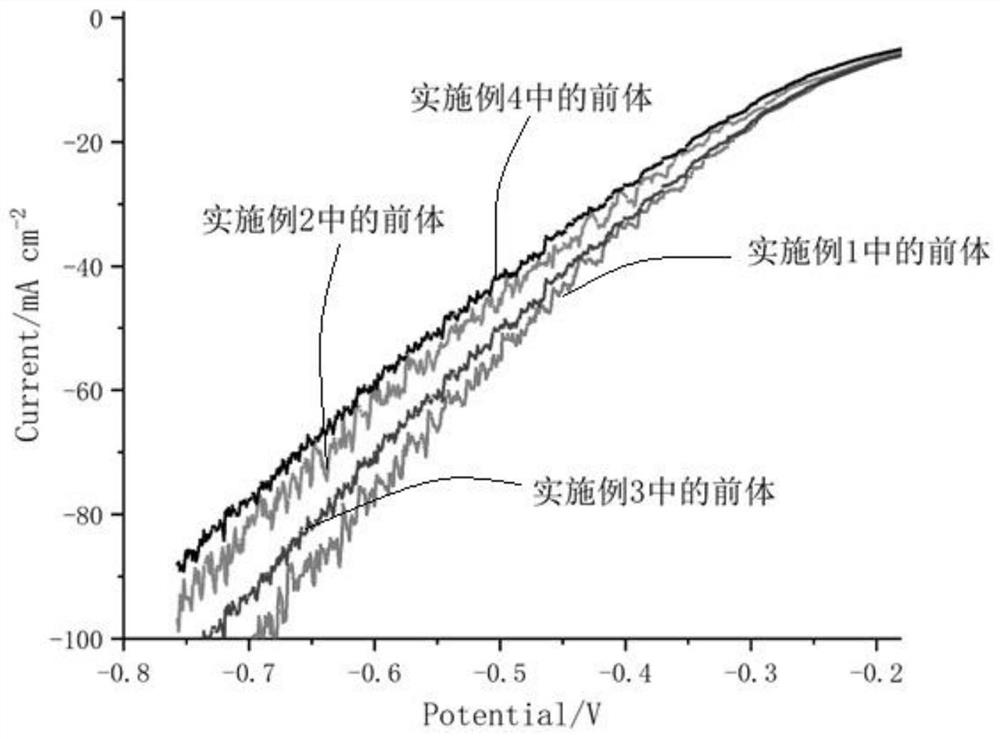

Embodiment 2

[0034] The difference between this example and Example 1 is that the amount of thiourea in step 1) is 0.3 g.

Embodiment 3

[0036] The difference between this embodiment and embodiment 1 is that the heating temperature of the electric blast drying oven in step 4) is 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com