Method for treating chlorotoluene rectification tail gas

A treatment method, the technology of chlorotoluene, applied in the direction of gas treatment, separation method, chemical instrument and method, etc., can solve the problem of low added value of acid, achieve high recovery efficiency, avoid resource waste, and achieve good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

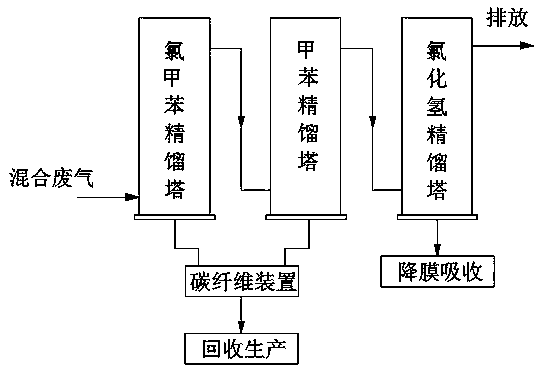

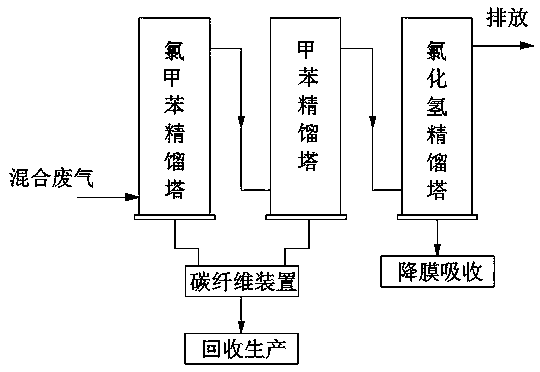

Image

Examples

Embodiment 1

[0030] According to the above method, the mixed waste gas containing hydrogen chloride, toluene and chlorotoluene is treated. The main devices used in this embodiment include a chlorotoluene rectification tower, a toluene rectification tower, and a hydrogen chloride rectification tower, all of which are stainless steel packed towers with ceramic fillers inside. Spray seals are 4m respectively 3 / (m 2 , h), 5m 3 / (m 2 , h), 5m 3 / (m 2 , h), 4m 3 / (m 2 , h).

[0031] The composition of the mixed waste gas containing hydrogen chloride, toluene and chlorotoluene is 1wt% toluene, 1.5wt% chlorotoluene, and the rest is 97.5wt% hydrogen chloride.

[0032] The solvent A used is methanol, the solvent B used is clay, and the solvent C used is n-butanol.

[0033] The saturated solvent A is desorbed in the rectification tower at a temperature of 170°C to obtain chlorotoluene with a product purity of 98%. The saturated solvent B is desorbed in a rectification tower at a temperature ...

Embodiment 2

[0035] According to the above method, the mixed waste gas containing hydrogen chloride, toluene and chlorotoluene is treated. The main devices used in this embodiment include a chlorotoluene rectification tower, a toluene rectification tower, and a hydrogen chloride rectification tower, all of which are stainless steel packed towers with ceramic fillers inside. Spray seals are 7m respectively 3 / (m 2 , h), 8m 3 / (m 2 , h), 6m 3 / (m 2 , h), 8m 3 / (m 2 , h).

[0036] The composition of the mixed waste gas containing hydrogen chloride, toluene and chlorotoluene is 1.5wt% toluene, 1.0wt% chlorotoluene, and the rest is 97.5wt% hydrogen chloride.

[0037] The solvent A used is butylsulfone, the solvent B used is clay, and the solvent C used is glycerol.

[0038] The saturated solvent A is desorbed in the rectification tower at a temperature of 120°C to obtain chlorotoluene with a product purity of 96%. The saturated solvent B is desorbed in a rectification tower at a tempera...

Embodiment 3

[0040] According to the above method, the mixed waste gas containing hydrogen chloride, toluene and chlorotoluene is treated. The main devices used in this embodiment include a chlorotoluene rectification tower, a toluene rectification tower, and a hydrogen chloride rectification tower, all of which are stainless steel packed towers with ceramic fillers inside. Spray seals are 5m respectively 3 / (m 2 , h), 7m 3 / (m 2 , h), 4m 3 / (m 2 , h), 6m 3 / (m 2 , h).

[0041] The composition of the mixed waste gas containing hydrogen chloride, toluene and chlorotoluene is 4.0wt% toluene, 3.0wt% chlorotoluene, and the rest is 93wt% hydrogen chloride.

[0042] The solvent A used is butylsulfone, the solvent B used is clay, and the solvent C used is diethyl carbonate.

[0043]The saturated solvent A is desorbed in the rectification tower at a desorption temperature of 190°C to obtain chlorotoluene with a product purity of 97%. The saturated solvent B is desorbed in a rectification t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com