Encapsulation method and application of zif-hemin based on melamine sponge

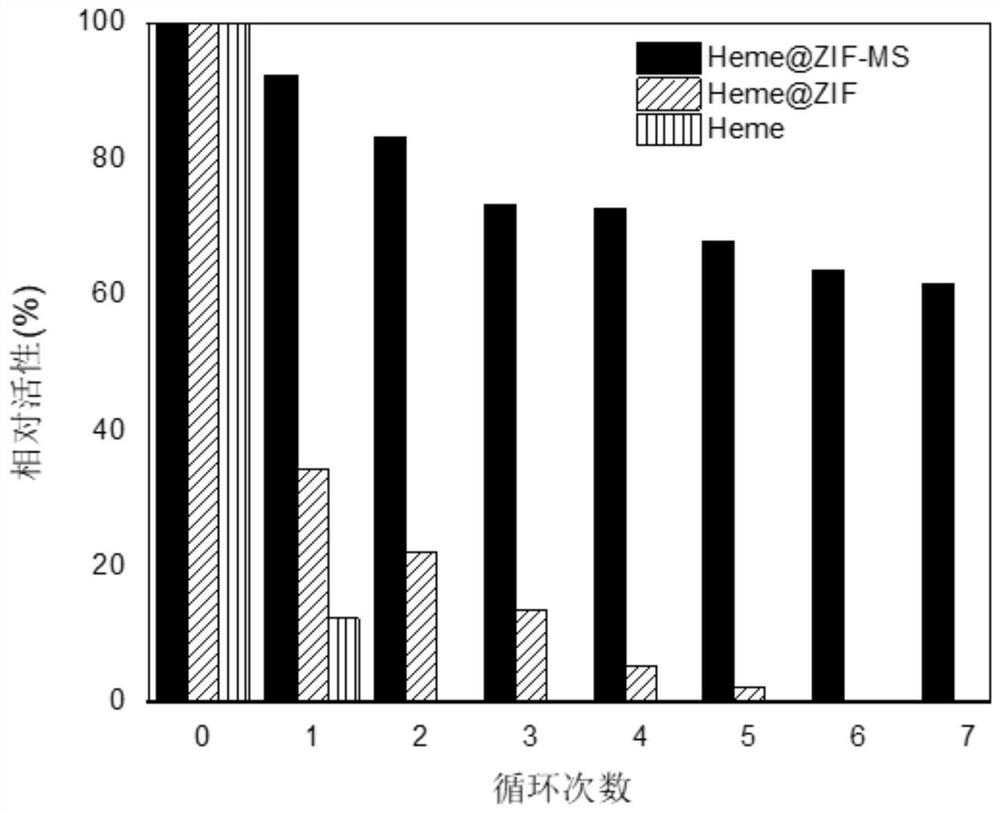

A technology of melamine sponge and hemin, which is applied in the field of nanomaterials, can solve problems such as easy agglomeration and difficult separation, and achieve the effects of simple synthesis method, excellent catalytic and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

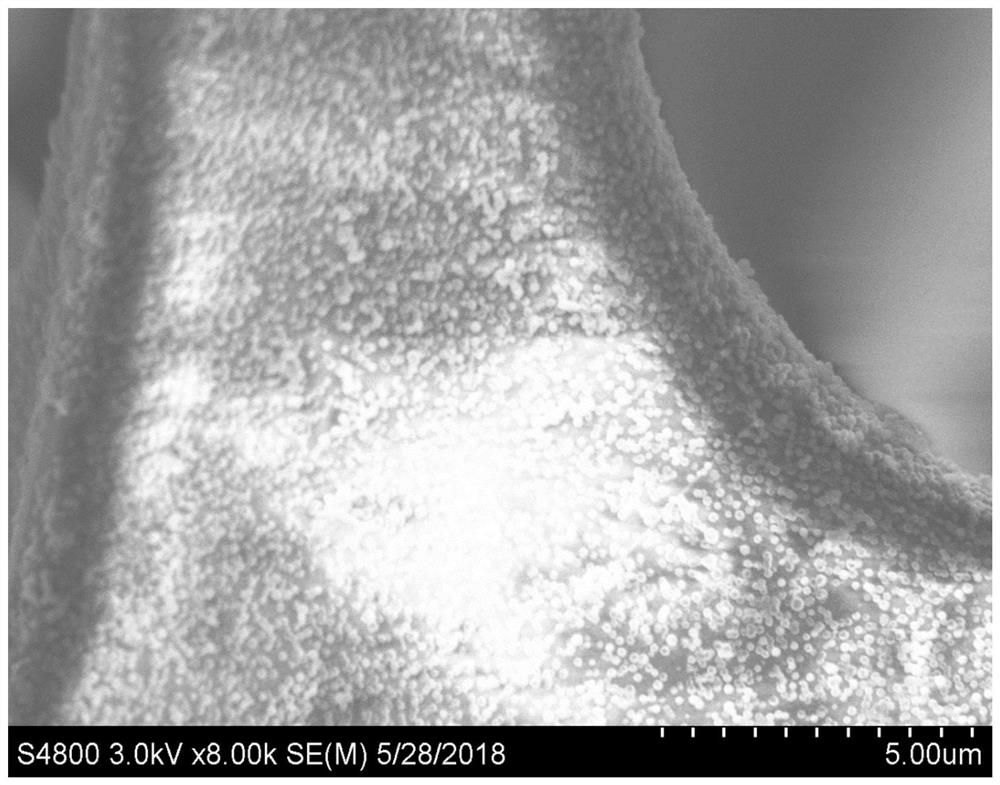

[0027] The encapsulation method based on melamine sponge loaded ZIF-hemin provided by the present embodiment comprises the following steps:

[0028] 1) 1.0g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 0.2g hemin in 20ml ethanol, stir at room temperature for 20min, add 0.7g 2-methylimidazole as an organic ligand, and react for 4h;

[0029] 2) centrifuging the product obtained in step 1), washing with ethanol to obtain a black product, and drying it in an oven at 40° C. to obtain a ZIF-loaded hemin material;

[0030] 3) Load the ZIF-loaded hemin material obtained in step 2) on three melamine sponges, specifically weigh 1.0 g of the ZIF-loaded hemin material in 100 ml of absolute ethanol, To obtain a mixed solution, immerse the melamine sponge material block in the mixed solution, ultrasonically react for 2h, then condense and reflux at 80°C for 4.5h, then centrifuge and wash twice with absolute ethanol at a speed of 300rpm, and place at 60°C Dry under vacuum to obtain a three-dimensional ...

Embodiment 2

[0032] The encapsulation method based on melamine sponge loaded ZIF-hemin provided by the present embodiment comprises the following steps:

[0033] 1) 1.2g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 0.25g of hemin in 20ml of ethanol, stir at room temperature for 30min, add 0.8g of 2-methylimidazole as an organic ligand, and react for 4h;

[0034] 2) centrifuging the product obtained in step 1), washing with ethanol to obtain a black product, and drying it in an oven at 60° C. to obtain a ZIF-loaded hemin material;

[0035] 3) The ZIF-loaded hemin material obtained in the step 2) is loaded on 5 melamine sponges, specifically, 1.2 g of the ZIF-loaded hemin material is weighed and dispersed in 120 ml of absolute ethanol to obtain Mix the solution, immerse the melamine sponge material block in the mixed solution, ultrasonically react for 2.5h, then condense and reflux at 90°C for 5.0h, then centrifuge and wash with absolute ethanol at a speed of 400rpm for 3 times, and vacuum dry at 70°C. ...

Embodiment 3

[0037] The encapsulation method based on melamine sponge loaded ZIF-hemin provided by the present embodiment comprises the following steps:

[0038] 1) 1.5g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 0.3g of hemin in 20ml of ethanol, stir at room temperature for 40min, add 0.9g of 2-methylimidazole as an organic ligand, and react for 4h;

[0039] 2) centrifuging the product obtained in step 1), washing with ethanol to obtain a black product, and drying it in an oven at 80° C. to obtain a ZIF-loaded hemin material;

[0040] 3) The ZIF-loaded hemin material obtained in step 2) is loaded on 7 melamine sponges. The difference between this embodiment and Example 1 is that 1.5g of ZIF-loaded chlorine is weighed in step 3). The heme material is dispersed in 150ml of absolute ethanol to obtain a mixed solution, the melamine sponge material block is immersed in the mixed solution, ultrasonically reacted for 3h, then condensed and refluxed at 100°C for 6h, and then refluxed with absolute ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com