Claw type ultrasonic transducer

An ultrasonic transducer and transducer technology, applied in the direction of fluid using vibration, etc., can solve the problems of power limitation, low uniformity of radiation sound field, and uniformity of sound field in a single sound radiation direction, so as to improve uniformity and improve The effect of sound radiation efficiency and sound field range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

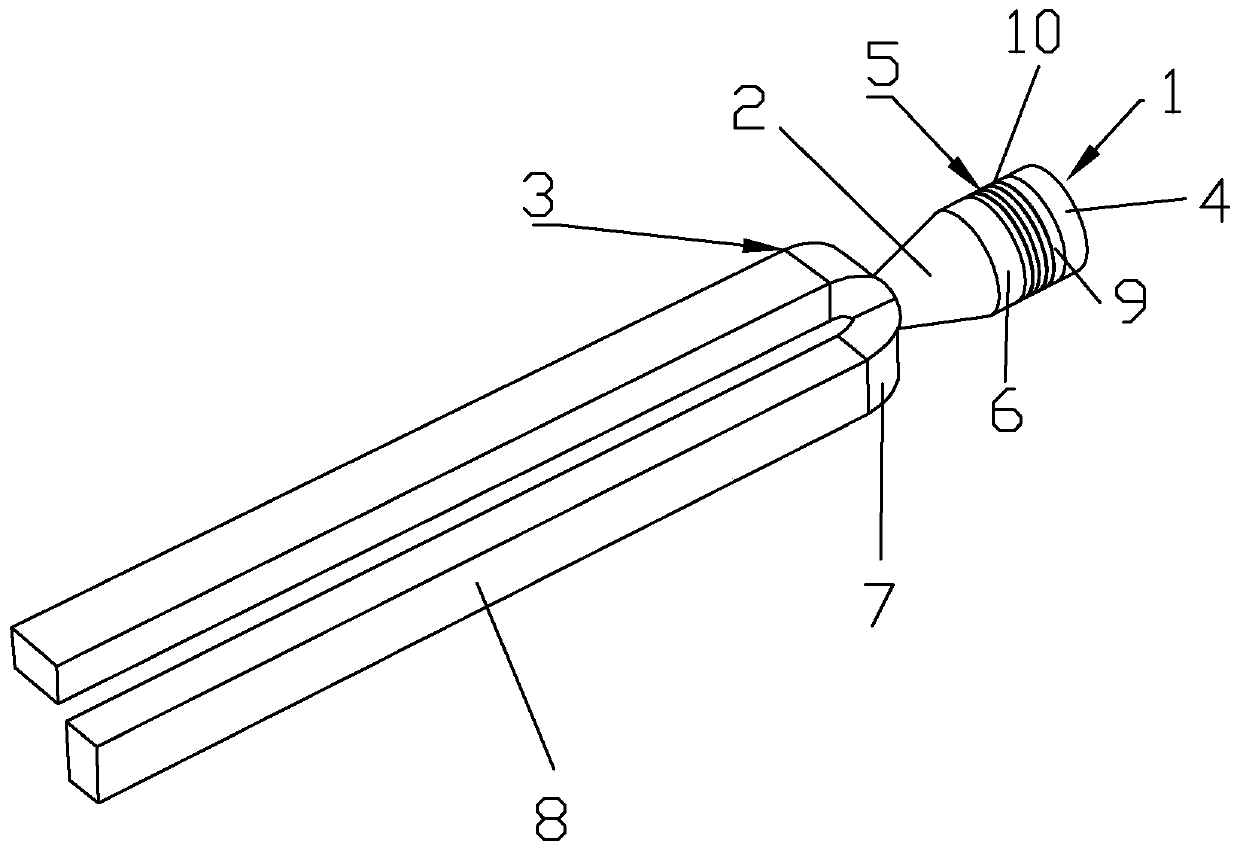

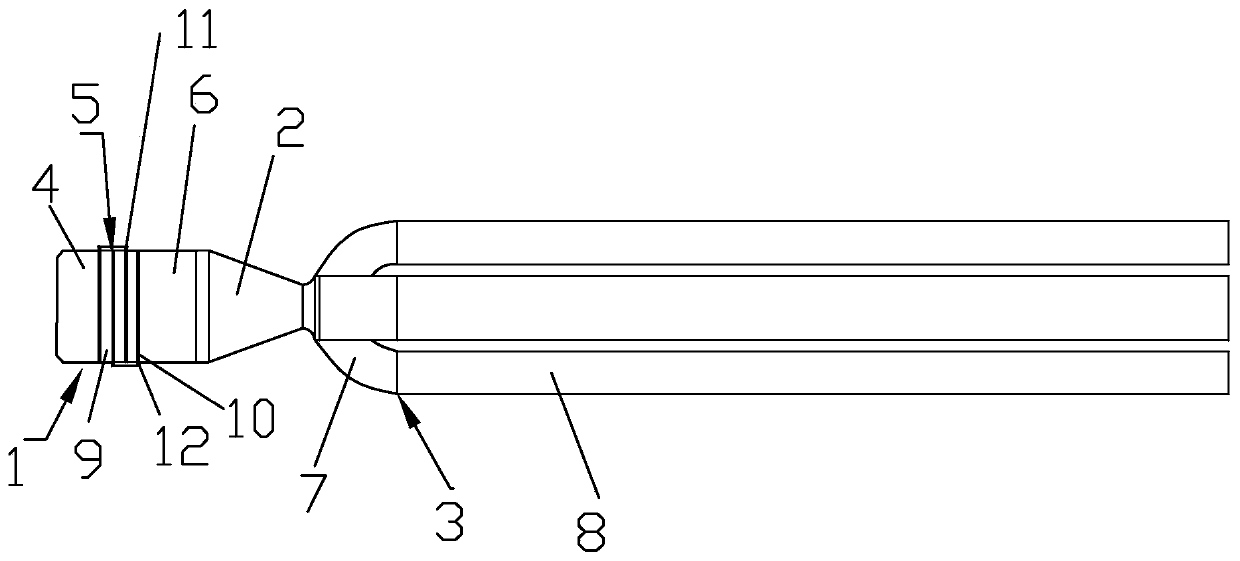

[0030] like Figure 1 to Figure 4Shown is a claw-type ultrasonic transducer of the present invention, including a sandwich-type piezoelectric ultrasonic transducer 1, a horn 2 and a claw-type omnidirectional radiator 3, and one end of the horn 2 is connected to a sandwich-type piezoelectric transducer. The ultrasonic transducer 1 is fixedly connected, and the other end of the horn 2 is fixedly connected with the claw-type omnidirectional radiator 3. The sandwich-type piezoelectric ultrasonic transducer 1 includes a rear cover 4, a piezoelectric ceramic crystal stack 5 and a front cover Plate 6, rear cover plate 4, piezoelectric ceramic crystal pile 5 and front cover plate 6 are fixed together by stress bolts, claw type omnidirectional radiator 3 includes claw bottom 7 and claw finger 8, one end of claw bottom 7 is connected to the amplitude The rod 2 is fixedly connected, and the claw finger 8 is fixedly connected to the other end of the claw bottom 7. The claw bottom 7 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com