Preparation method of non-magnetic drill pipe for directional drilling of coal mine tunnel

A non-magnetic drill pipe and directional drilling technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low drilling efficiency, low hole formation rate, poor stability, etc., to improve the strength of drill pipe, improve Abrasion resistance, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

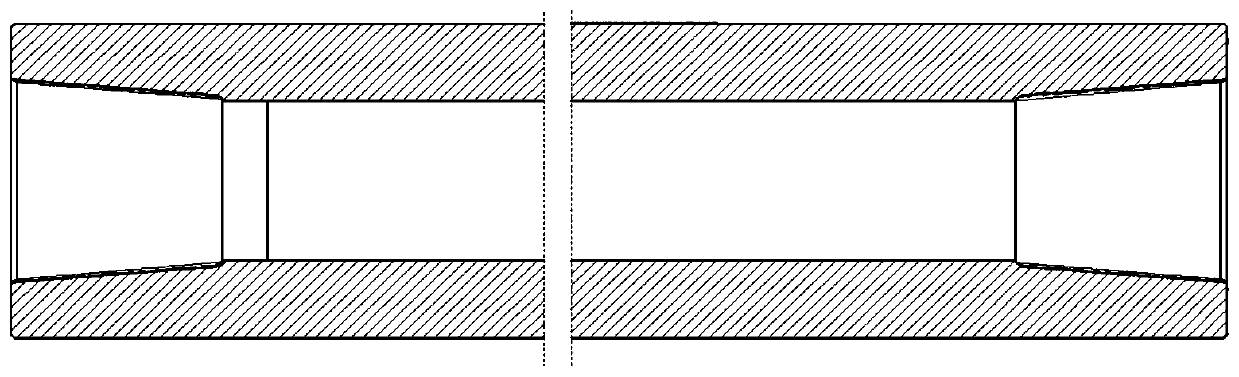

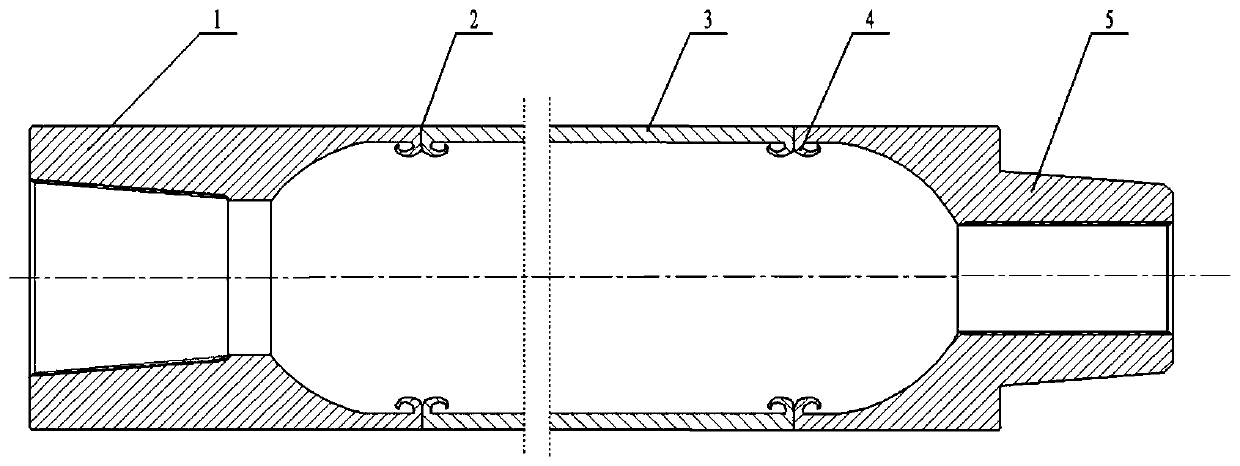

[0033] Under the premise of ensuring that the outer diameters of the rod body 3 , the female joint 1 and the male joint 5 are consistent, the inner diameter of the rod body 3 can be larger than the inner diameter of the steel pipe of the female joint 1 and the male joint 5 . Specifically, the preparation method of the non-magnetic drill rod for directional drilling in coal mine tunnels of the present invention comprises the following steps:

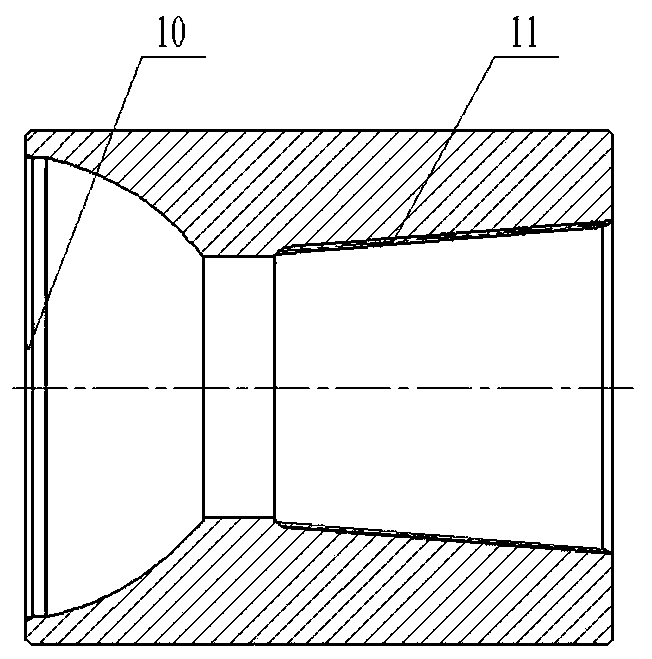

[0034] Step 1: The female joint and the male joint in the non-magnetic drill pipe need to be hardened, wherein the machining and threading of the female joint 1 and the male joint 5 can be completed first, and one end of the female joint 1 is provided with a female joint welding surface 10 , the other end is machined to form an internal thread 11, one end of the male joint 5 is provided with a male joint welding surface 50, and the other end is machined to form an external thread 52, and the internal thread 11 and the external thread 52 ar...

Embodiment 1

[0050] Taking the Ф89mm friction-welded non-magnetic drill pipe as an example, the drill pipe is equipped with a ZDY12000LD directional drilling rig and a Ф120 drill bit for geological drilling tests. The mud pulse wireless measurement-while-drilling method is used for directional pilot hole construction on site, with a cumulative footage of 200m and no magnetic field. The drill pipe did not break or stick, and the test results were good, which met the construction requirements of the project.

Embodiment 2

[0052] Take the Ф63.5mm friction-welded non-magnetic drill pipe as an example. The processing technology is the same as that of the Ф89mm non-magnetic drill pipe. The accumulative construction footage was 600m, during which no breakage or sticking occurred, and the test results were good, meeting the construction needs of the project.

[0053] Therefore, the present invention adopts the conventional three-section processing method of the drill pipe, divides the non-magnetic steel drill pipe into three parts of the male joint, the female joint and the rod body for processing, and welds them together through continuous drive friction welding. Since the friction welding seam of non-magnetic steel has to undergo high-temperature thermal cycles, hard and brittle σ phases are precipitated in the weld seam, resulting in a decrease in the strength of the weld seam. Strength increased to 700MPa.

[0054] Because the rod body and the joint are processed separately, the wall thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com