Preparation method for low-density heat-proof composite material rotation solid workpiece

A composite material, low-density technology, applied in the direction of weight reduction, can solve the problems of reducing the success rate of parts preparation, sensitive to pressure response, increasing the cost of parts, etc., to optimize the size and position relationship, prevent deformation or damage, improve success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

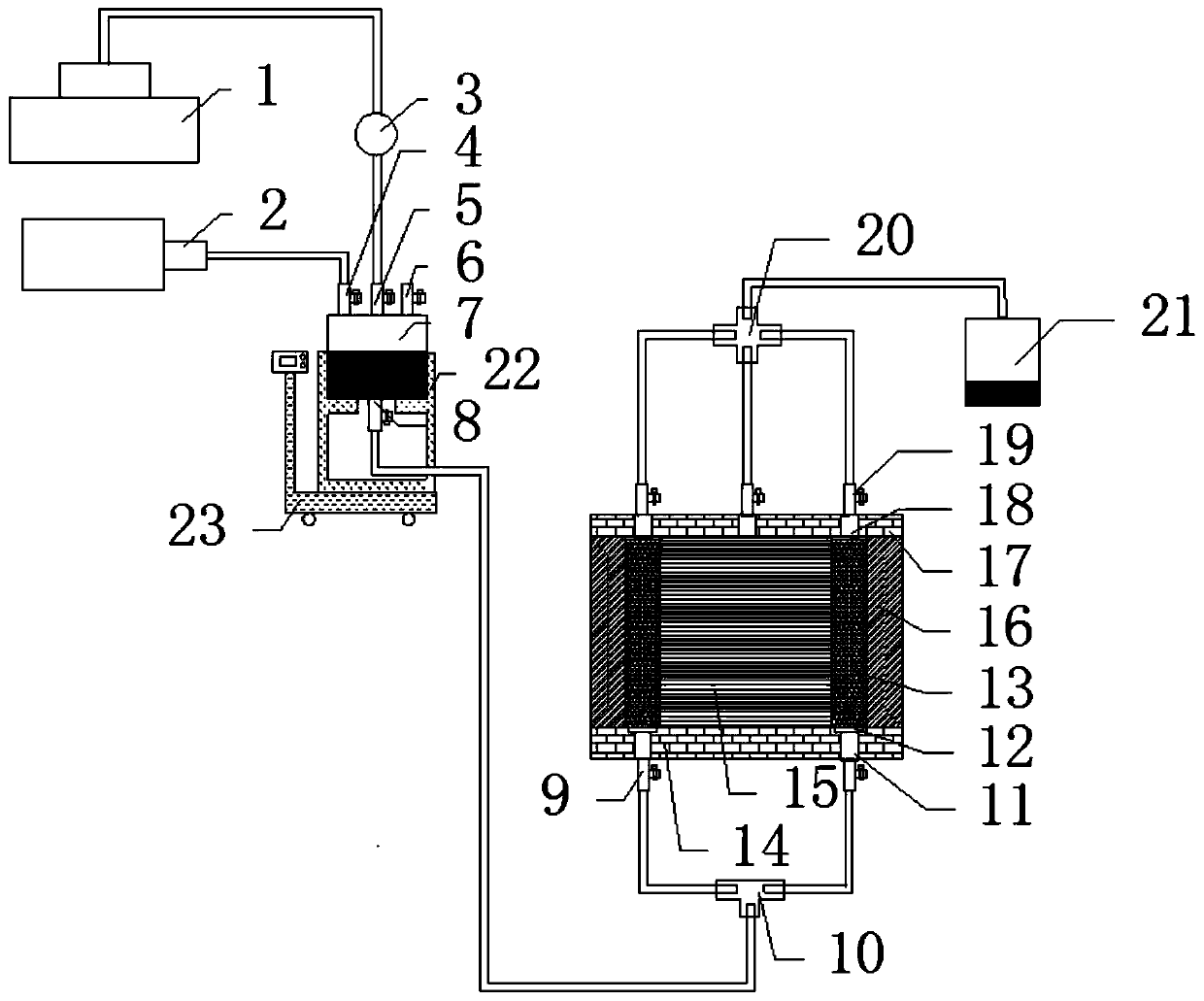

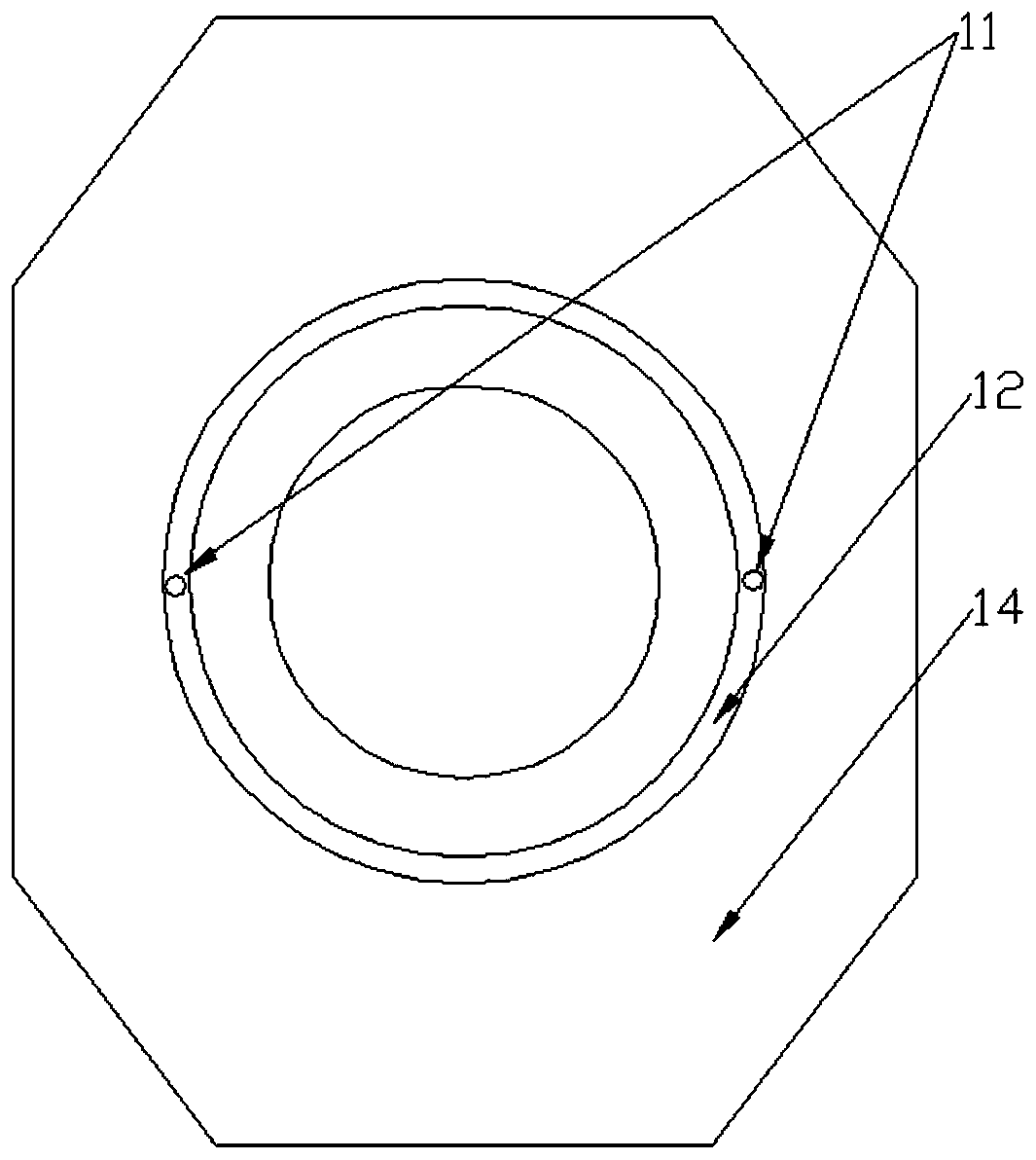

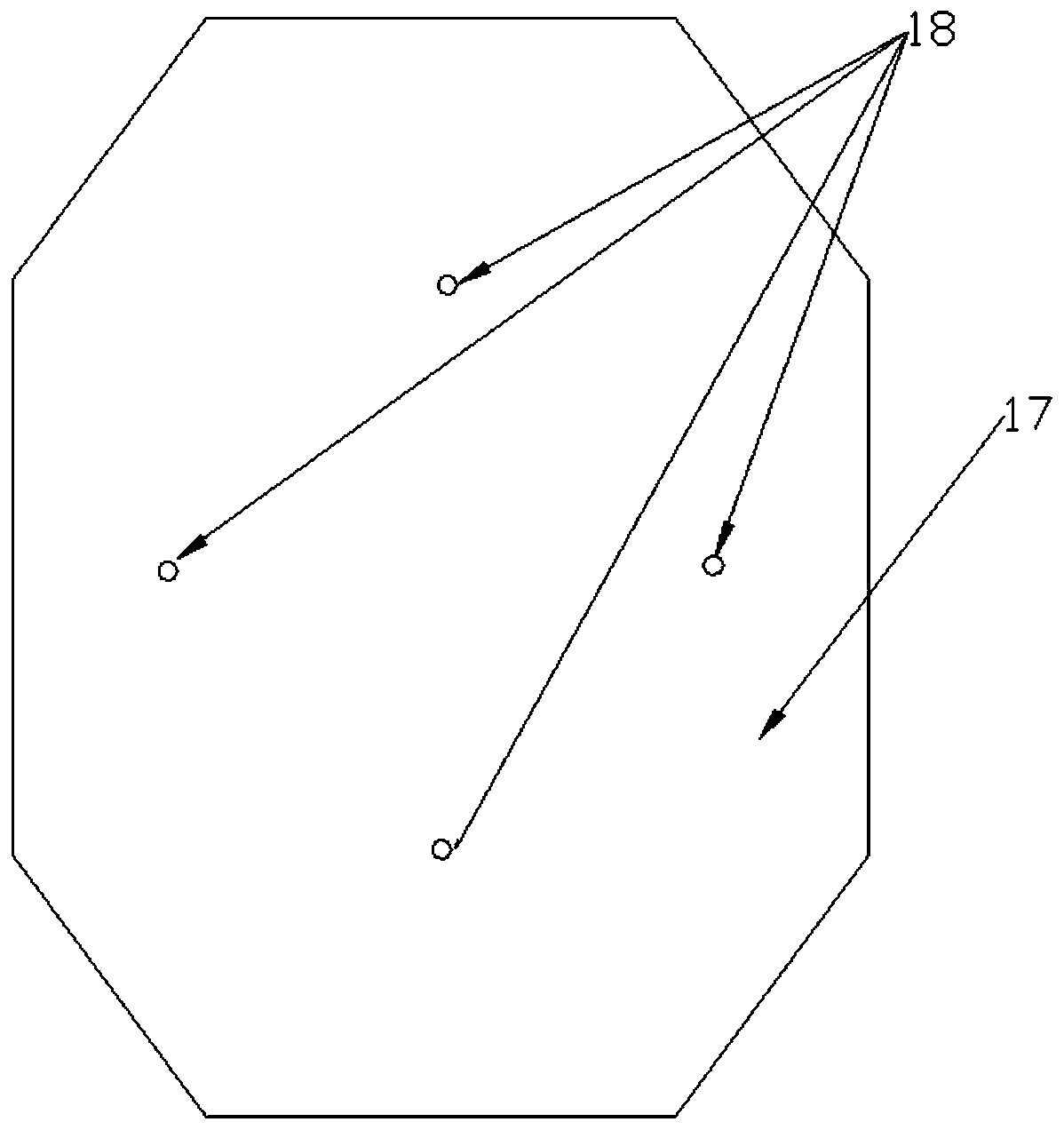

[0048] A glue injection system for low-density heat-resistant composite rotary parts, such as figure 1 As shown, the system includes a glue storage device, a mold, and a waste liquid tank 21 connected in sequence by pipelines. A prefabricated body 13 is arranged inside the mold, and resin sol is installed in the glue storage device. The resin sol is poured into the mold from the glue storage device through pipelines. , and fully infiltrate the prefabricated body 13, and the excess resin sol is discharged into the waste liquid bucket 21 through the pipeline. Wherein, the density of preform 13 is 0.1-0.5g / cm 3 ; The viscosity of the resin sol is 10-500mPa·s.

[0049] The glue storage device includes a compressed air pump 1, a vacuum pump 2 and a material tank 7. The resin sol is stored in the material tank 7. The upper part of the material tank 7 is connected to the compressed air pump 1 through the air pressure pipeline, and connected to the vacuum pump 2 through the vacuum pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com