Embroidered wall painting and preparation method thereof

A technology of embroidery and wall painting, applied in the field of embroidery wall painting and its preparation, can solve the problems of high cost and single color of wall painting, and achieve the effects of strong functionality, rich application fields, and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

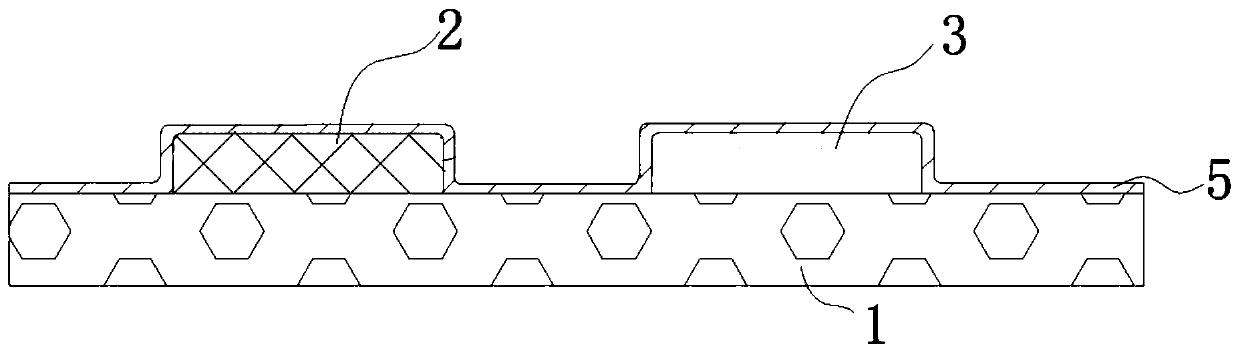

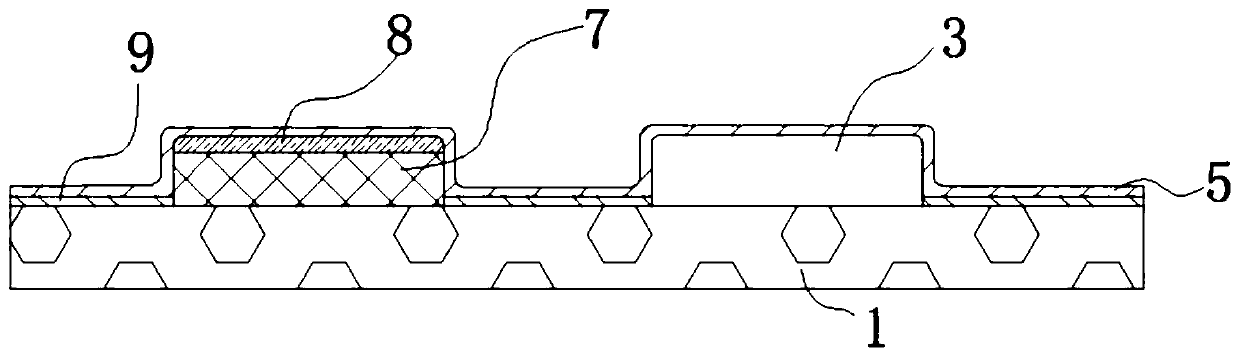

[0112] The present invention also provides a method for preparing the embroidery wall painting described in the above technical solution, comprising the following steps:

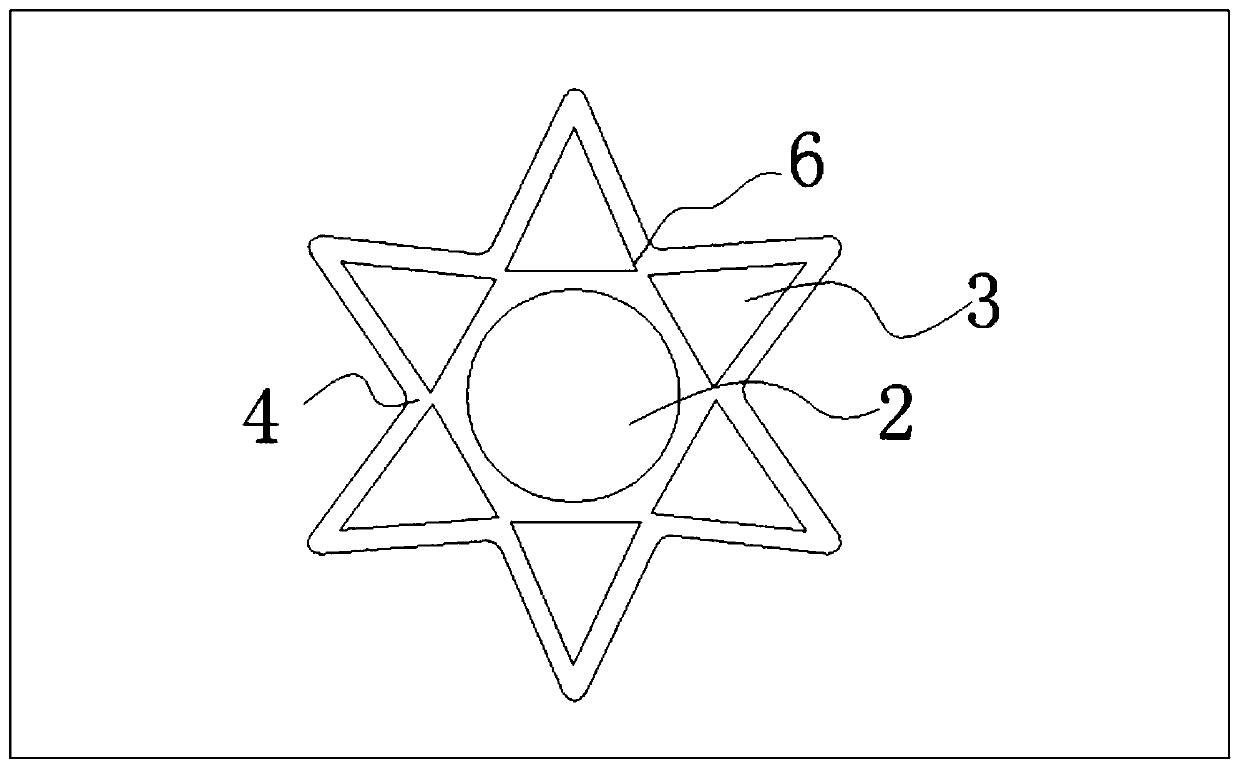

[0113] a) dividing the substrate layer into an image area, an embroidery area and a background color area;

[0114] b) printing foam paste in the image area;

[0115] printing ink on the foaming slurry and the ground color area to form an ink layer and a ground color layer respectively, and then heating the base material coated with the foaming slurry to form a foaming layer;

[0116] Or obtain a digital image layer by digital printing in the image area;

[0117] c) performing embroidery in the embroidery area to obtain an embroidery layer;

[0118] d) painting the resin composition on the embroidery layer, the image layer and the ground color area as a whole to form a protective layer to obtain an embroidery wall picture.

[0119] In the present invention, the substrate layer is firstly divided into an i...

Embodiment 1

[0132] (1) Print the outline of the pattern on the surface of the non-woven fabric with a thickness of 1mm, and divide the image area, embroidery area and background color area;

[0133] (2) Rotary screen printing foaming slurry in the image area (the foaming slurry includes the following components: 120 parts by weight of acrylate resin, 1 part by weight of polydimethylsiloxane, 1.5 parts by weight of potassium zinc stabilizer Parts by weight, 7 parts by weight of foaming agent, 15 parts by weight of calcium carbonate, 30 parts by weight of titanium dioxide, 3 parts by weight of polyvinyl alcohol, 2 parts by weight of wormwood powder, 1.5 parts by weight of Mengzong bamboo extract, 75 parts by weight of butyl acetate, 1.5 parts by weight of CT catalyst), after drying, a foaming slurry layer is formed, and the water-based ink is letterpress printed on the foaming slurry layer and the ground color area to form an ink layer and a ground color layer respectively, and heating (subs...

Embodiment 2

[0138] The preparation method provided by Example 1 is used to obtain embroidery wall paintings; the difference is that the foaming slurry includes the following components: 120 parts by weight of acrylate resin, 1 part by weight of polydimethylsiloxane, and 1.5 parts by weight of potassium zinc stabilizer. Parts by weight, 7 parts by weight of foaming agent, 15 parts by weight of calcium carbonate, 30 parts by weight of titanium dioxide, 3 parts by weight of polyvinyl alcohol, 2 parts by weight of wormwood powder, 3 parts by weight of ammonium dihydrogen phosphate, 75 parts by weight of butyl acetate , 2 parts by weight of CT catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com