Red phosphorus/zinc oxide heterojunction film for realizing photocatalysis disinfection by utilizing screen LED light, and preparation method and application thereof

A zinc oxide and heterojunction technology, applied in coatings and other directions, can solve the problems of limited activity, poor photocatalytic efficiency of ZnO, and low charge separation efficiency, achieve good light transmission, improve photocatalytic activity, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

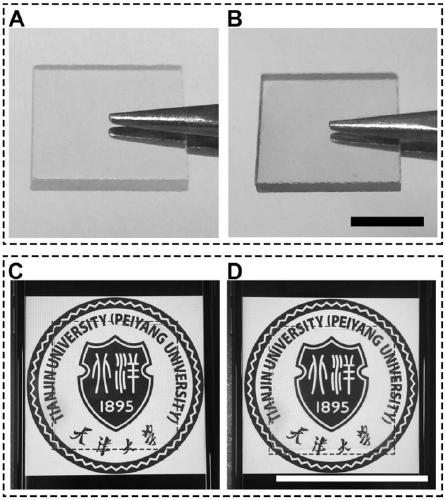

[0054] A preparation method of red phosphorus-zinc oxide heterojunction film using LED photocatalytic disinfection includes the following steps:

[0055] Step 1. Pretreatment of the substrate. The substrate is sequentially placed in acetone, absolute ethanol and deionized water for ultrasonic cleaning for 15 minutes, and dried naturally at room temperature. The substrate is glass;

[0056] Step 2. Prepare red phosphorous film,

[0057] After the completion of step 1, the surface of the substrate obtained by chemical vapor deposition (CVD) is used to prepare a red phosphorous film, including:

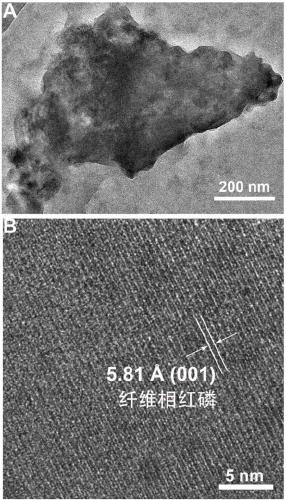

[0058] 1) Red phosphorus powder pretreatment: Put the red phosphorus powder at 200°C, hydrothermally treat it for 12 hours, and slowly drop to room temperature. The resulting powder is vacuum dried and then ground to below 100 microns to complete the red phosphorus powder pretreatment;

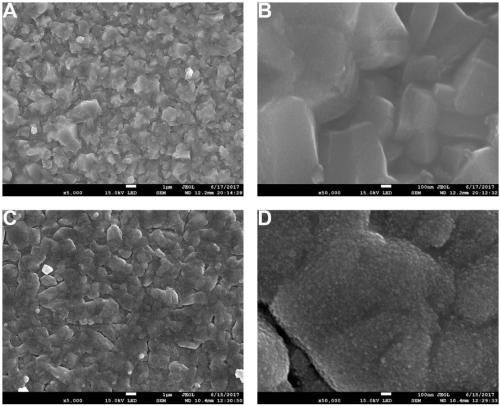

[0059] 2) Put the pretreated red phosphorous and the cleaned quartz glass in a CVD furnace to perform the red p...

Embodiment 2

[0063] A preparation method of red phosphorus-zinc oxide heterojunction film using LED photocatalytic disinfection includes the following steps:

[0064] Step 1. Pretreatment of the substrate. The substrate is sequentially placed in acetone, absolute ethanol and deionized water for ultrasonic cleaning for 15 minutes, and dried naturally at room temperature. The substrate is glass;

[0065] Step 2. Prepare red phosphorous film,

[0066] After the completion of step 1, the surface of the substrate obtained by chemical vapor deposition (CVD) is used to prepare a red phosphorous film, including:

[0067] 1) Red phosphorus powder pretreatment: Put the red phosphorus powder at 200°C, hydrothermally treat it for 12 hours, and slowly drop to room temperature. The resulting powder is vacuum dried and then ground to below 100 microns to complete the red phosphorus powder pretreatment;

[0068] 2) Put the pretreated red phosphorous and the cleaned quartz glass in a CVD furnace to perform the red p...

Embodiment 3

[0072] A preparation method of red phosphorus-zinc oxide heterojunction film using LED photocatalytic disinfection includes the following steps:

[0073] Step 1. Pretreatment of the substrate. The substrate is sequentially placed in acetone, absolute ethanol and deionized water for ultrasonic cleaning for 15 minutes, and dried naturally at room temperature. The substrate is glass;

[0074] Step 2. Prepare red phosphorous film,

[0075] After the completion of step 1, the surface of the substrate obtained by chemical vapor deposition (CVD) is used to prepare a red phosphorous film, including:

[0076] 1) Red phosphorus powder pretreatment: Put the red phosphorus powder at 200°C, hydrothermally treat it for 12 hours, and slowly drop to room temperature. The resulting powder is vacuum dried and then ground to below 100 microns to complete the red phosphorus powder pretreatment;

[0077] 2) Put the pretreated red phosphorous and the cleaned quartz glass in a CVD furnace to perform the red p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com