High-performance prefabricated part for slag blocking wall of main runner of blast furnace, and preparation method and construction method thereof

A construction method and high-performance technology, applied in the direction of manufacturing tools, ceramic molding machines, discharge devices, etc., can solve problems such as difficult operation, limited application range, complex structure, etc., to avoid oxidation, improve the life of the retaining wall, and cost-effective Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

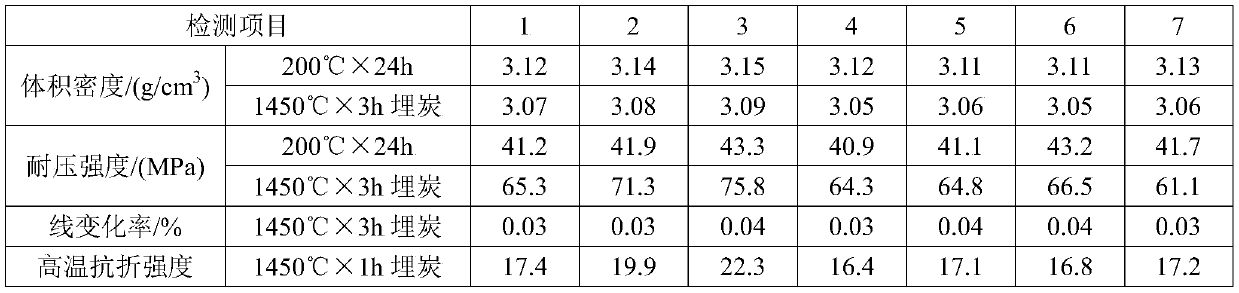

[0041] See Table 1 for the raw material ratio of prefabricated parts for high-performance blast furnace main ditch slag retaining wall.

[0042] A. Put fused white corundum, silicon carbide, titanium dioxide, manganese-aluminum spinel, carbon-containing resin powder, metal silicon powder, borax, and wetting agent into a mixer, and mix evenly to obtain a mixture a;

[0043] Among them, Al in fused white corundum 2 o 3 The weight content is 98%, and the bulk density is 3.6g / cm 3 , the gradation of fused white corundum is: 8mm-5mm 20kg, 5mm-3mm 15kg, 3mm-1mm 5kg; the weight content of SiC in silicon carbide is 97%, and the gradation of silicon carbide is: 3mm-1mm 10kg, 1- 0mm 20kg, 0.074-0mm 14.2kg; TiO in titanium dioxide 2 The weight content is 97%, the particle size is less than or equal to 0.074mm; MnAl in manganese aluminum spinel 2 o 4 The weight content of carbon-containing resin powder is 90%, the particle size is less than or equal to 0.074mm; carbon-containing resi...

Embodiment 2

[0048] See Table 1 for the raw material ratio of prefabricated parts for high-performance blast furnace main ditch slag retaining wall.

[0049] A. Put fused white corundum, silicon carbide, titanium dioxide, manganese-aluminum spinel, carbon-containing resin powder, metal silicon powder, borax, and wetting agent into a mixer, and mix evenly to obtain a mixture a;

[0050] Among them, Al in fused white corundum 2 o 3 The weight content is 98%, and the bulk density is 3.6g / cm 3 , the gradation of fused white corundum is: 8mm-5mm 20kg, 5mm-3mm 15kg, 3mm-1mm 5kg; the weight content of SiC in silicon carbide is 97%, and the gradation of silicon carbide is: 3mm-1mm 10kg, 1- 0mm 18kg, 0.074-0mm 12kg; TiO in titanium dioxide 2 The weight content is 97%, the particle size is less than or equal to 0.074mm; MnAl in manganese aluminum spinel 2 o 4 The weight content of carbon-containing resin powder is 90%, the particle size is less than or equal to 0.074mm; carbon-containing resin ...

Embodiment 3

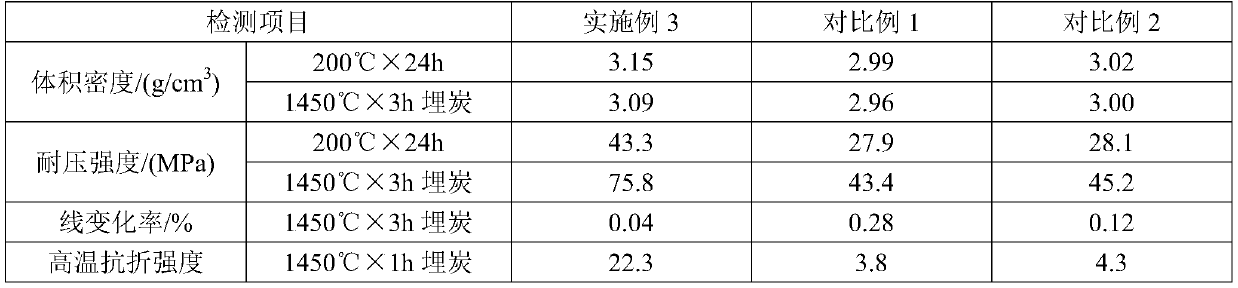

[0055] See Table 1 for the raw material ratio of prefabricated parts for high-performance blast furnace main ditch slag retaining wall.

[0056] A. Put fused white corundum, silicon carbide, titanium dioxide, manganese-aluminum spinel, carbon-containing resin powder, metal silicon powder, borax, and wetting agent into a mixer, and mix evenly to obtain a mixture a;

[0057] Among them, Al in fused white corundum 2 o 3 The weight content is 98%, and the bulk density is 3.6g / cm 3 , the gradation of fused white corundum is: 8mm-5mm 18kg, 5mm-3mm 15kg, 3mm-1mm 5kg; the weight content of SiC in silicon carbide is 97%, and the gradation of silicon carbide is: 3mm-1mm 10kg, 1- 0mm 16kg, 0.074-0mm 10.6kg; TiO in titanium dioxide 2 The weight content is 97%, the particle size is less than or equal to 0.074mm; MnAl in manganese aluminum spinel 2 o 4 The weight content of carbon-containing resin powder is 90%, the particle size is less than or equal to 0.074mm; carbon-containing resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com