Chromium-containing solid waste and organic material synergistic pyrolysis harmless treatment device and method

A technology for the harmless treatment of organic materials, which is applied in the preparation of liquid hydrocarbon mixtures, special dry distillation, and the petroleum industry. problems, to achieve the effects of harmless treatment, reduction of residues, and improvement of heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention provides a device and method for the harmless treatment of chromium-containing solid waste and organic materials through synergistic pyrolysis. The specific technical method and device of the present invention will be described in detail and completely below in conjunction with the accompanying drawings and specific implementation methods. The described The specific implementation manners are only some examples of the present invention, not all examples. All other examples obtained by those skilled in the art without creative efforts belong to the protection scope of the present invention.

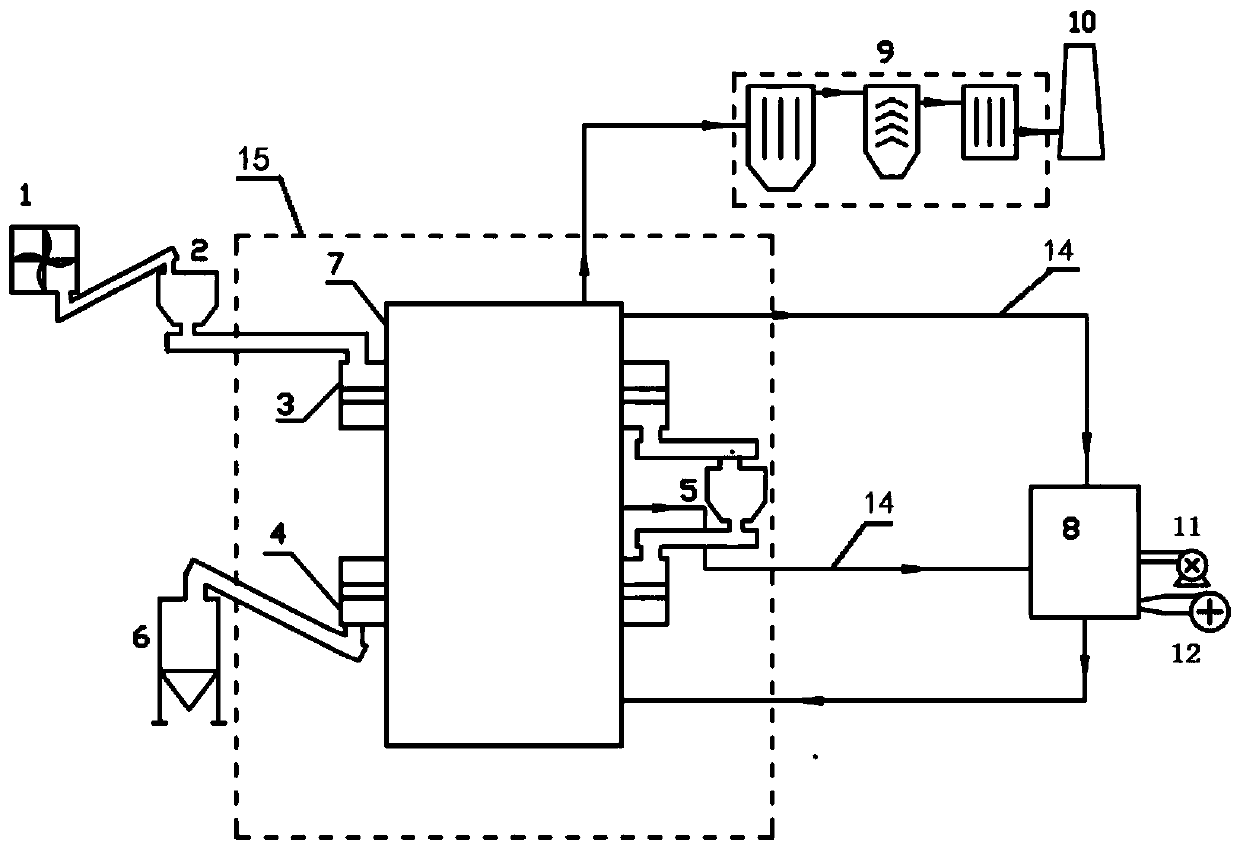

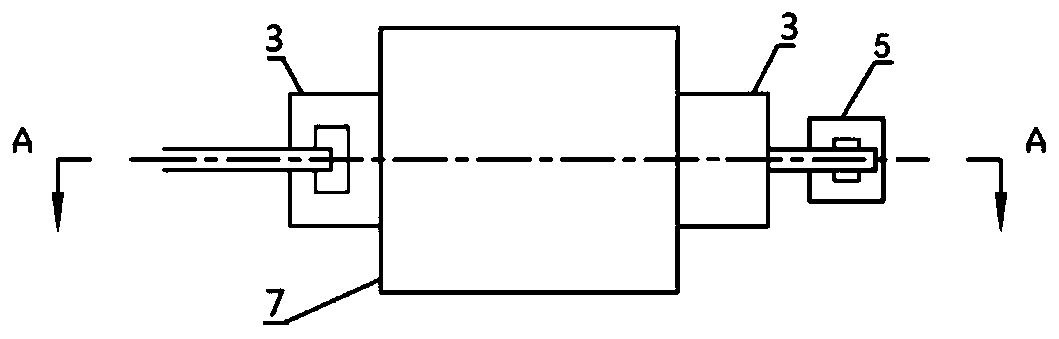

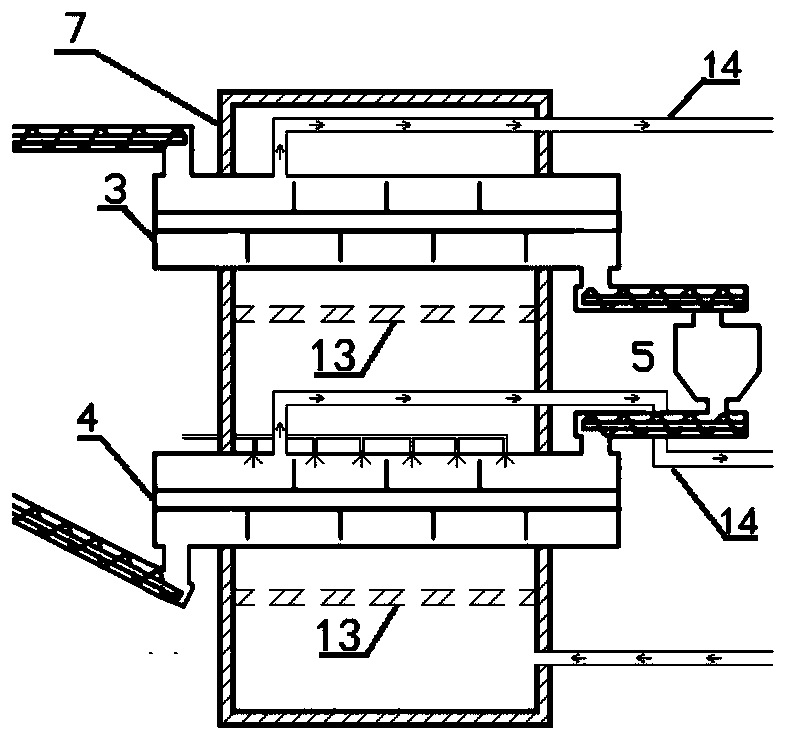

[0033] Such as figure 1 , figure 2 and image 3 As shown, a harmless treatment device for chromium-containing solid waste and organic material synergistic pyrolysis of the present invention includes crushing and mixing granulation equipment 1, a closed feed bin 2, residue output equipment 6, a combustible gas combustion chamber 8, and an exhaust gas Purific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com