High-load thrust sliding bearing capable of adjusting thermal deformation through self feedback

A technology for thrust sliding bearings and thermal deformation, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of increased friction, large bearing size, increased equipment loss and operating costs, etc., to reduce bearing bush bending, Improved bearing capacity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

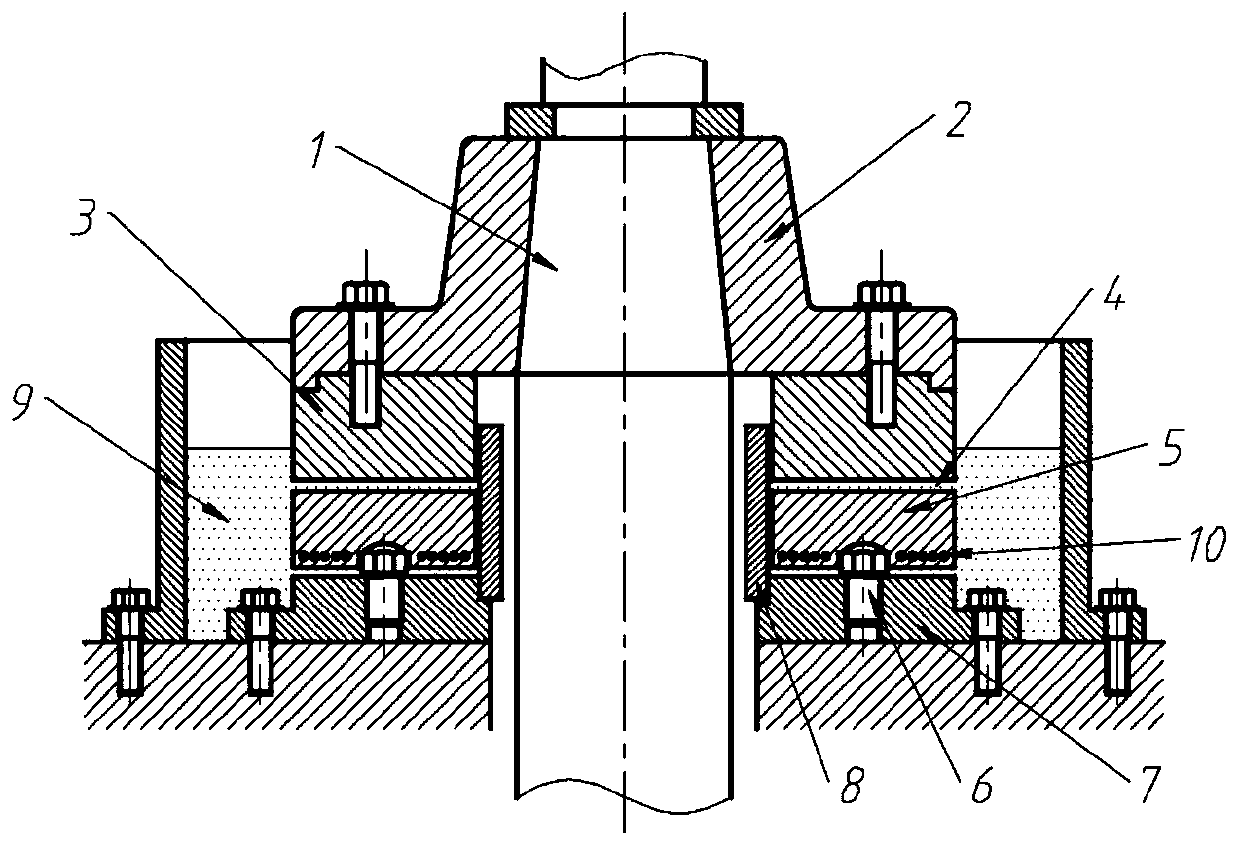

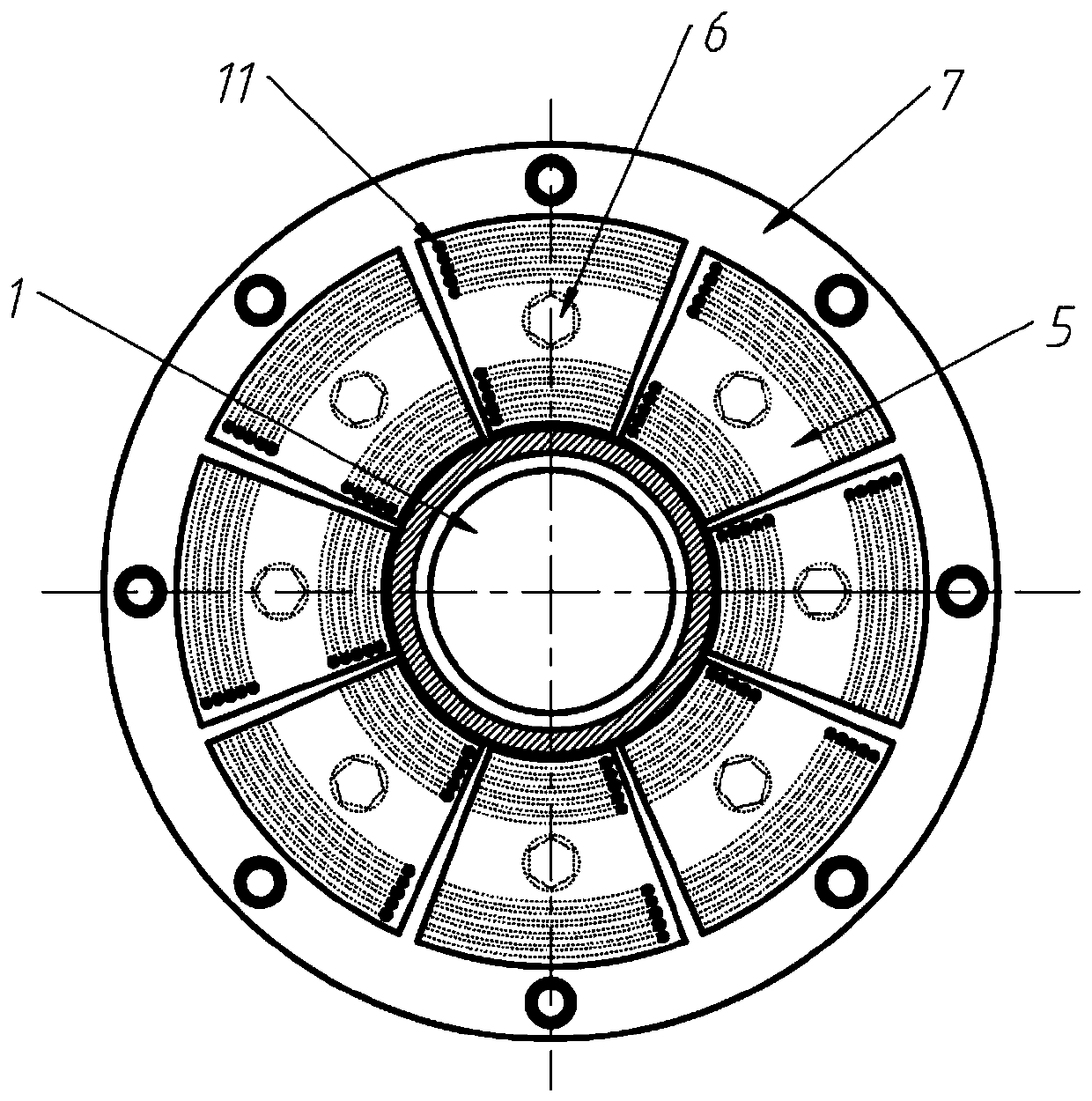

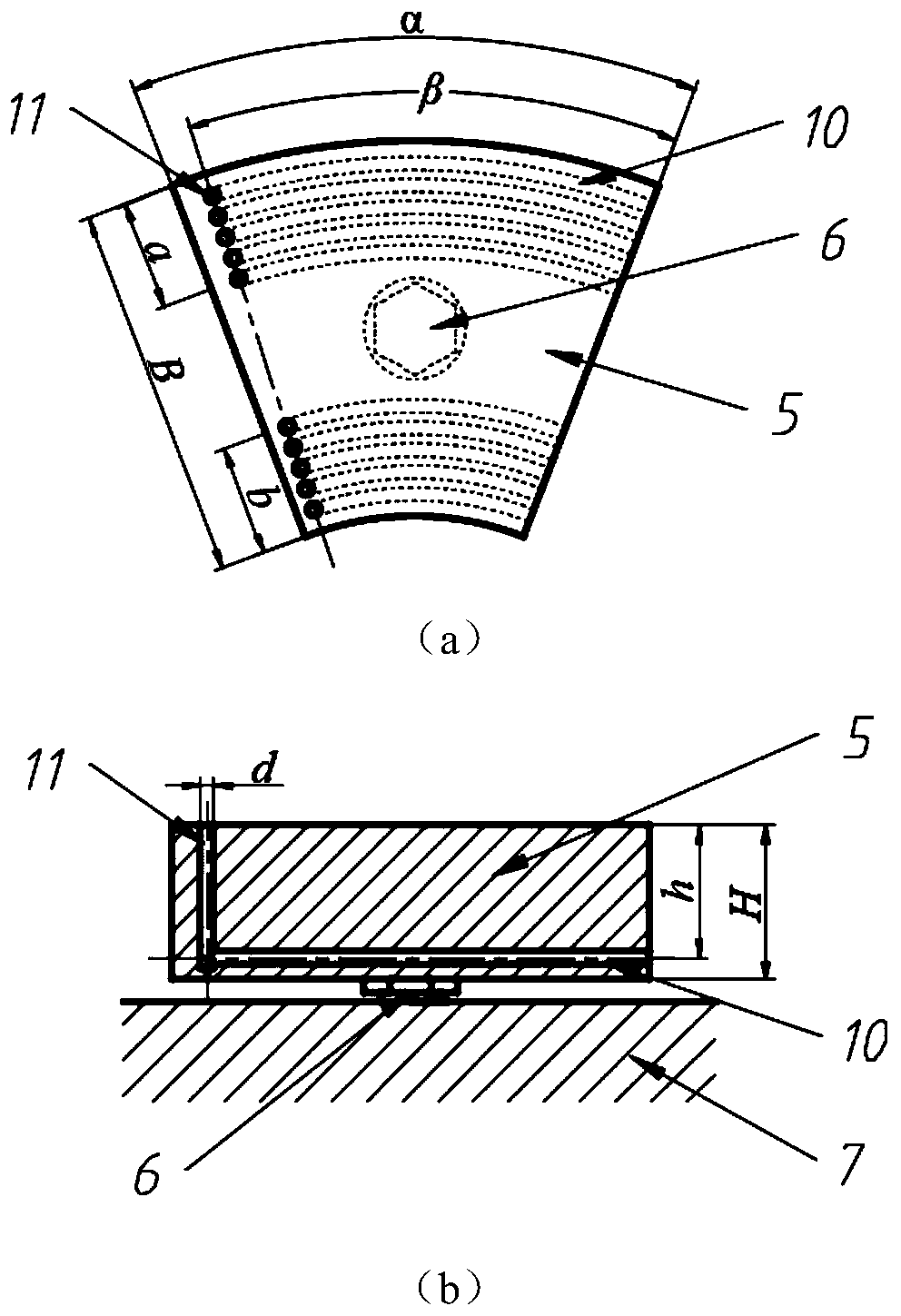

[0026] like figure 1 and figure 2 As shown, the present invention provides a self-feedback adjustable thermal deformation high-load thrust sliding bearing, including a rotor 1, an axial positioning base 2, a thrust plate 3, a bearing pad 5, a bearing fulcrum 6, and a fixed base 7 , oil deflector ring 8 and lubricating oil 9. Wherein, the thrust disc 3 is connected with the axial positioning base 2 which is axially fixed of the rotor 1, the thrust disc 3 is directly opposite to the bearing pad 5, and there is a bearing gap 4 in the middle, and there is a bearing fulcrum 6 at the middle position of the bottom of the bearing pad 5, And the bearing pad 5 can rotate around the bearing fulcrum 6 in a small range, the lower end of the bearing fulcrum 6 is fixed on the fixed base 7, and the side of the fixed base 7 close to the rotor 1 is assembled with the oil deflector ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com