Concrete self-shrinkage deformation and thermal expansion coefficient measuring device and measuring method

A technology of thermal expansion coefficient and measuring device, applied in the direction of material thermal expansion coefficient, material thermal development, etc., can solve problems such as inconsistency, not real temperature difference, concrete cracking, etc., and achieve the effect of convenient operation, simple production, and clear measurement principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

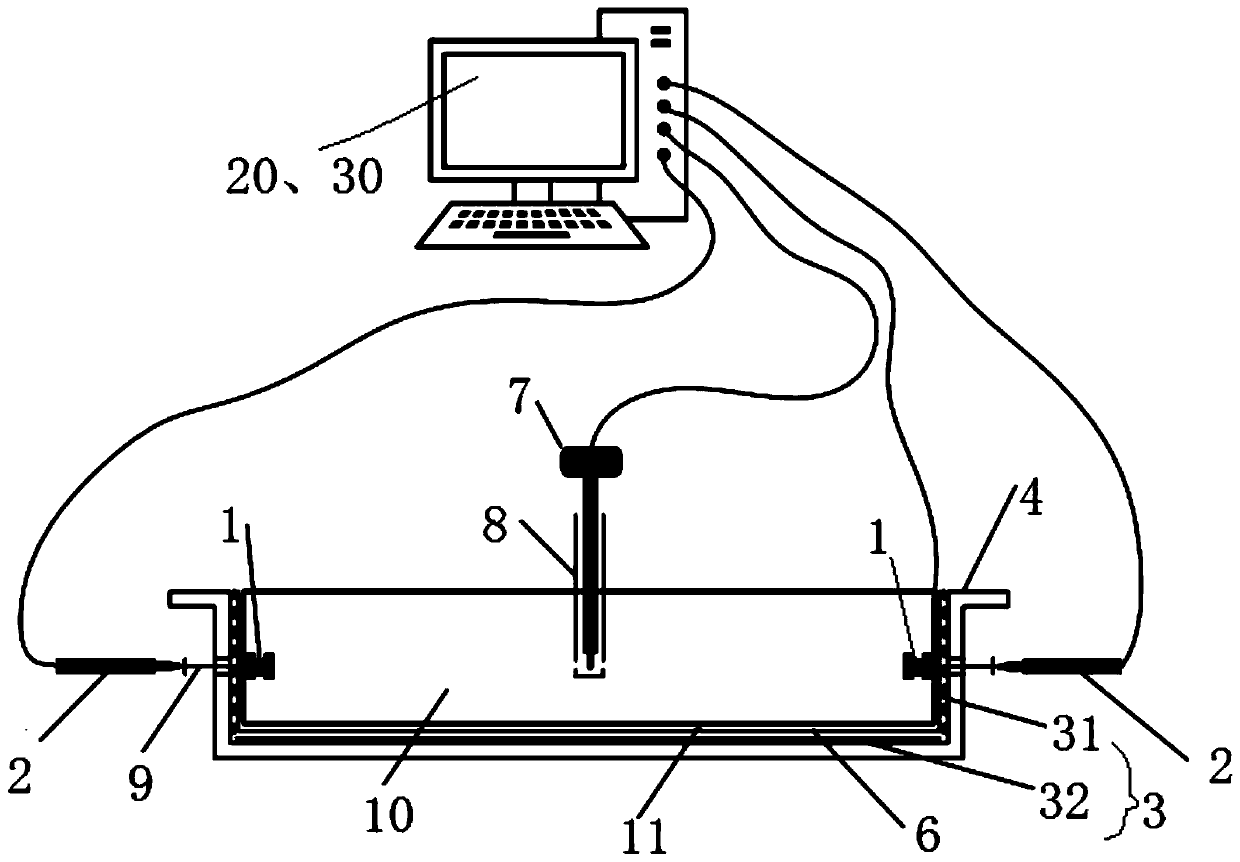

[0042] Example 1: Measurement of early autogenous shrinkage deformation of concrete

[0043] The cement used in the concrete of this embodiment is P.O 42.5 ordinary Portland cement; the fly ash used is a first-grade low-calcium ash, and its water demand ratio is 95%; the water reducer used is PCA-I type polycarboxylic acid high Performance superplasticizer with a solid content of 30%; the fine aggregate used is river sand with a fineness modulus of 2.6, which belongs to medium sand with a mud content <1%; the coarse aggregate used is limestone gravel with a particle size of 5~ 20mm continuous gradation.

[0044] The concrete mix ratio used is 240kg / m3 of cement, 60kg / m3 of fly ash, 186kg / m3 of water, 750kg / m3 of fine aggregate and 1150kg / m3 of coarse aggregate. The 28-day strength of the concrete used is 37MPa.

[0045] Adopt above-mentioned measuring device, measuring method comprises the following steps:

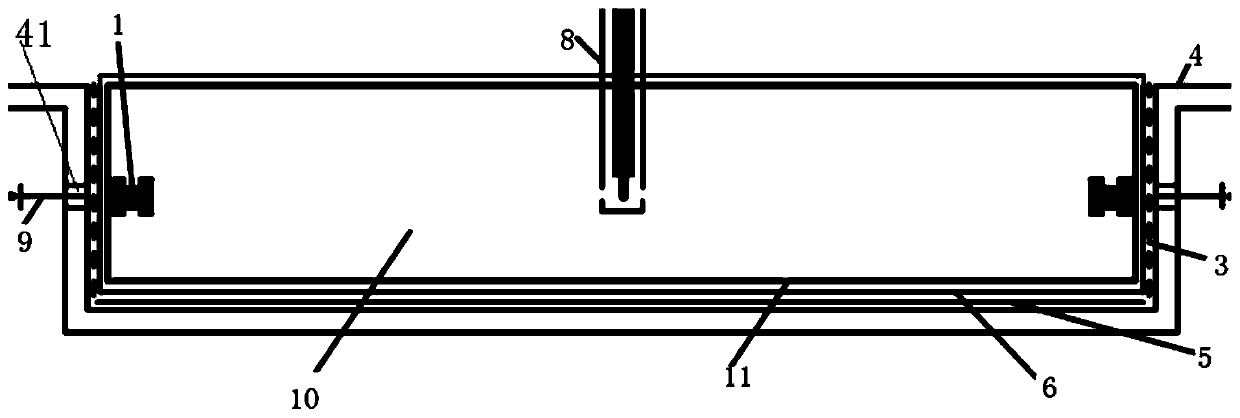

[0046] S11, in the mold 4, first install the polytetrafluoroethyle...

Embodiment 2

[0053] Example 2: Measurement of Early Thermal Expansion Coefficient of Concrete

[0054] The concrete raw materials and mix proportions used in embodiment two are the same as those in embodiment one, and will not be described again. Adopt above-mentioned measuring device, measuring method comprises the following steps:

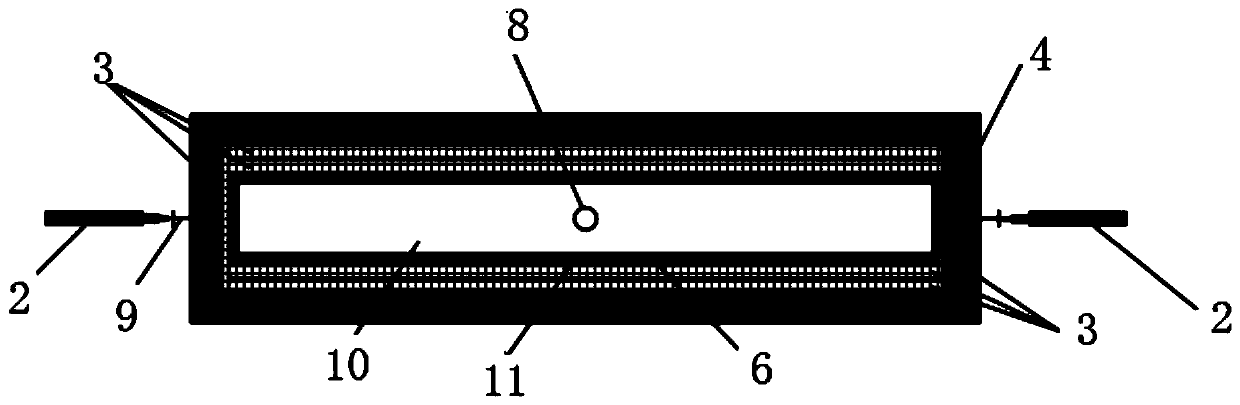

[0055] S11, in the mold 4, first install the polytetrafluoroethylene layer 32 and the liner 31, then install the temperature control software layer 6, then attach a layer of plastic film 11 inside the temperature control software layer 6, and finally install the probe 1 and a guide rod 9, one end of the guide rod 9 passes through the tunnel and is connected with the measuring head;

[0056] S12, pouring concrete in the mold 4, pre-embedding a temperature sensor installation pipe 8 at the center of the concrete specimen during pouring, the temperature sensor installation pipe 8 is used to install the temperature sensor 7;

[0057] S13, after pouring concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com