Millimeter wave MMIC heat dissipation package based on 3D heterogeneous integration technology

A millimeter-wave, heterogeneous technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problem of inability to take into account the millimeter-wave radio frequency front-end chip millimeter-wave microwave performance and heat conduction, limit the engineering application of millimeter-wave radio frequency front-end chips, and millimeter-wave radio frequency front-end chips. The microwave radio frequency front-end chip has the effect of shortening the interconnect size, ensuring electrical performance, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

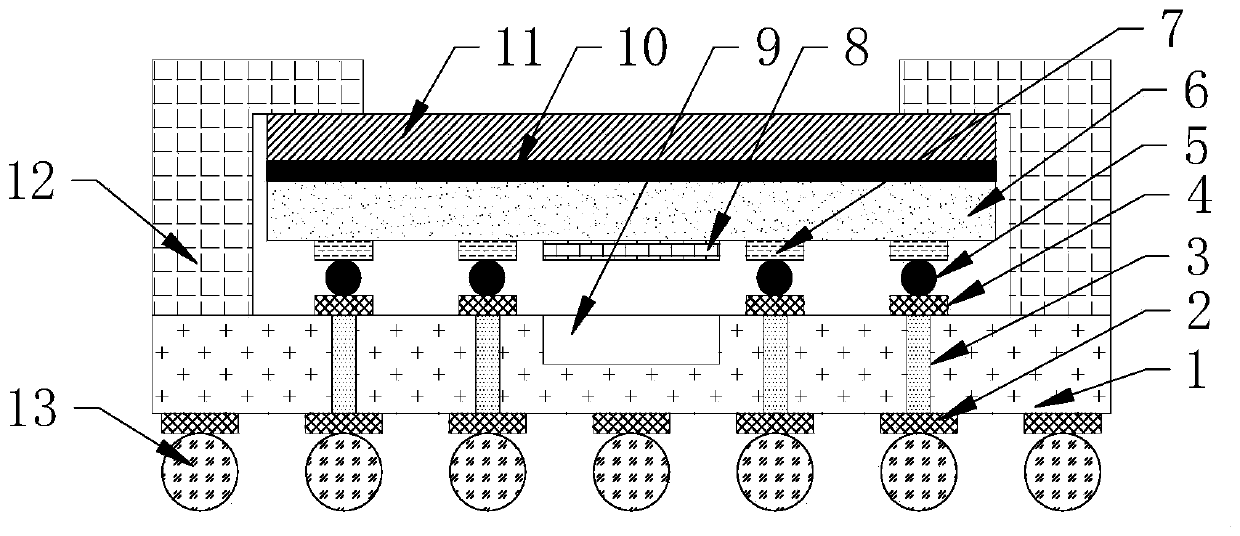

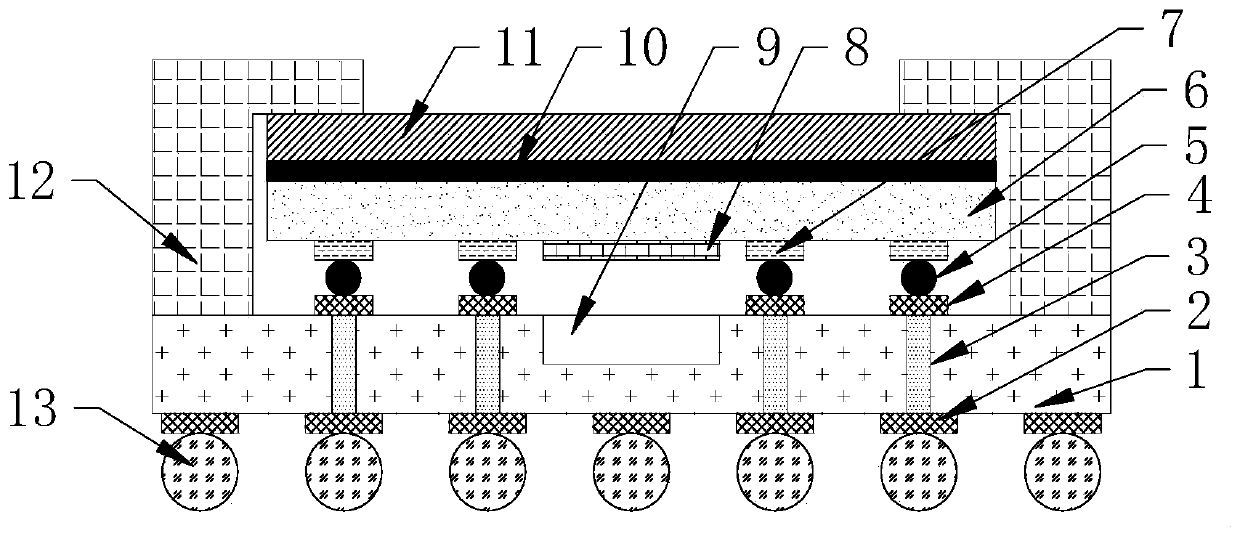

[0027] like figure 1 As shown, a millimeter-wave MMIC heat dissipation package based on 3D heterogeneous integration technology includes a packaging substrate 1, a transmission line 2 on the lower surface of the packaging substrate, a TSV via 3 arranged inside the packaging substrate, a transmission line 4 on the upper surface of the packaging substrate, and gold bumps. Point 5, millimeter wave GaAs MMIC6, metal PAD7 set on the surface of GaAs MMIC, millimeter wave circuit pattern 8 set on the surface of GaAs MMIC, cavity on the upper surface of the package substrate 9, high thermal conductivity adhesive material 10, heat dissipation metal block 11, Plastic encapsulation material 12 and BGA solder ball 13;

[0028] The transmission line 2 on the lower surface of the packaging substrate is connected to the transmission line 4 on the upper surface of the packaging substrate through the TSV via hole 3 provided inside the packaging substrate;

[0029] The GaAs MMIC6 is flipped fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com