Organic light-emitting diode and preparation method thereof

A light-emitting diode and organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of complicated preparation procedures and poor packaging effect of OLED light-emitting devices, and achieve simple process, improved service life, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

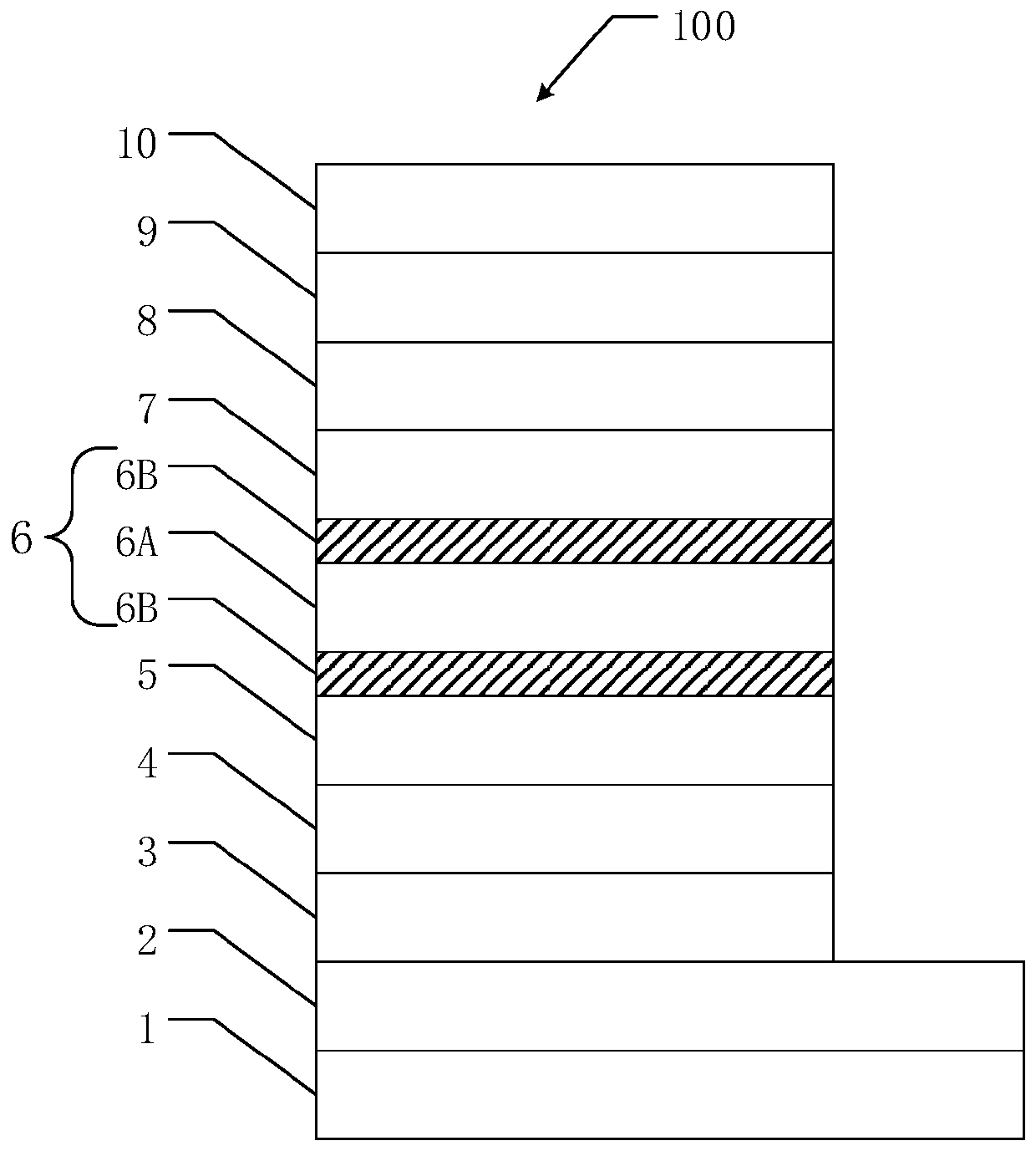

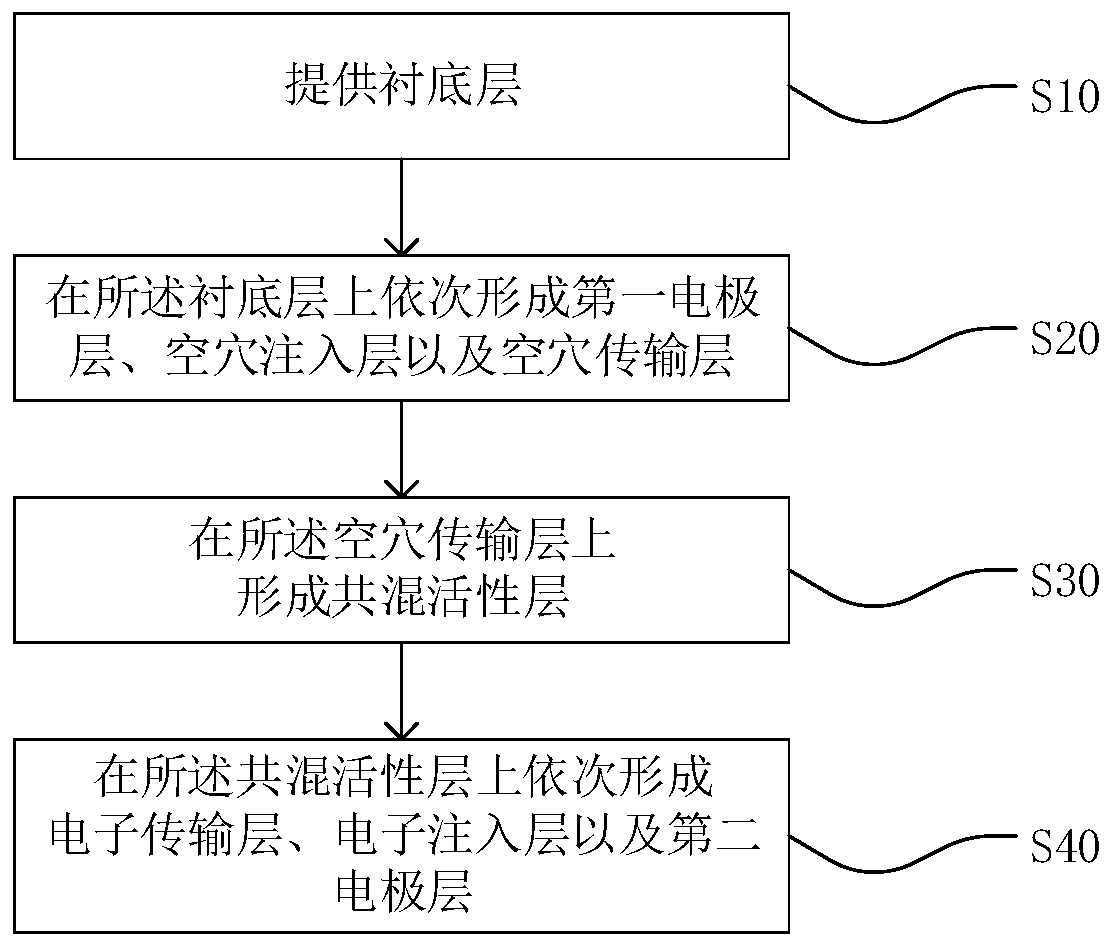

[0038] An organic light emitting diode 100 is disclosed in the embodiment of the present invention, such as figure 1 As shown, the organic light emitting diode 100 includes a substrate layer 1, a first electrode layer 2, a hole injection layer 3, a hole transport layer 4, an electron blocking layer 5, a blending active layer 6, a hole blocking layer 7, Electron transport layer 8 , electron injection layer 9 and second electrode layer 10 .

[0039] The material of the substrate layer 1 is polyimide (Polyimide, PI), which is a flexible substrate layer 1, which protects the structure of the organic light emitting diode 100 and enables the organic light emitting diode 100 to realize flexible display.

[0040] The first electrode layer 2 is arranged on the substrate layer 1, and the material of the first electrode layer 2 is indium tin oxide (ITO), which is used to provide a current and voltage for the organic light emitting diode 100 to promote hole Migrate to the luminescent lay...

Embodiment 2

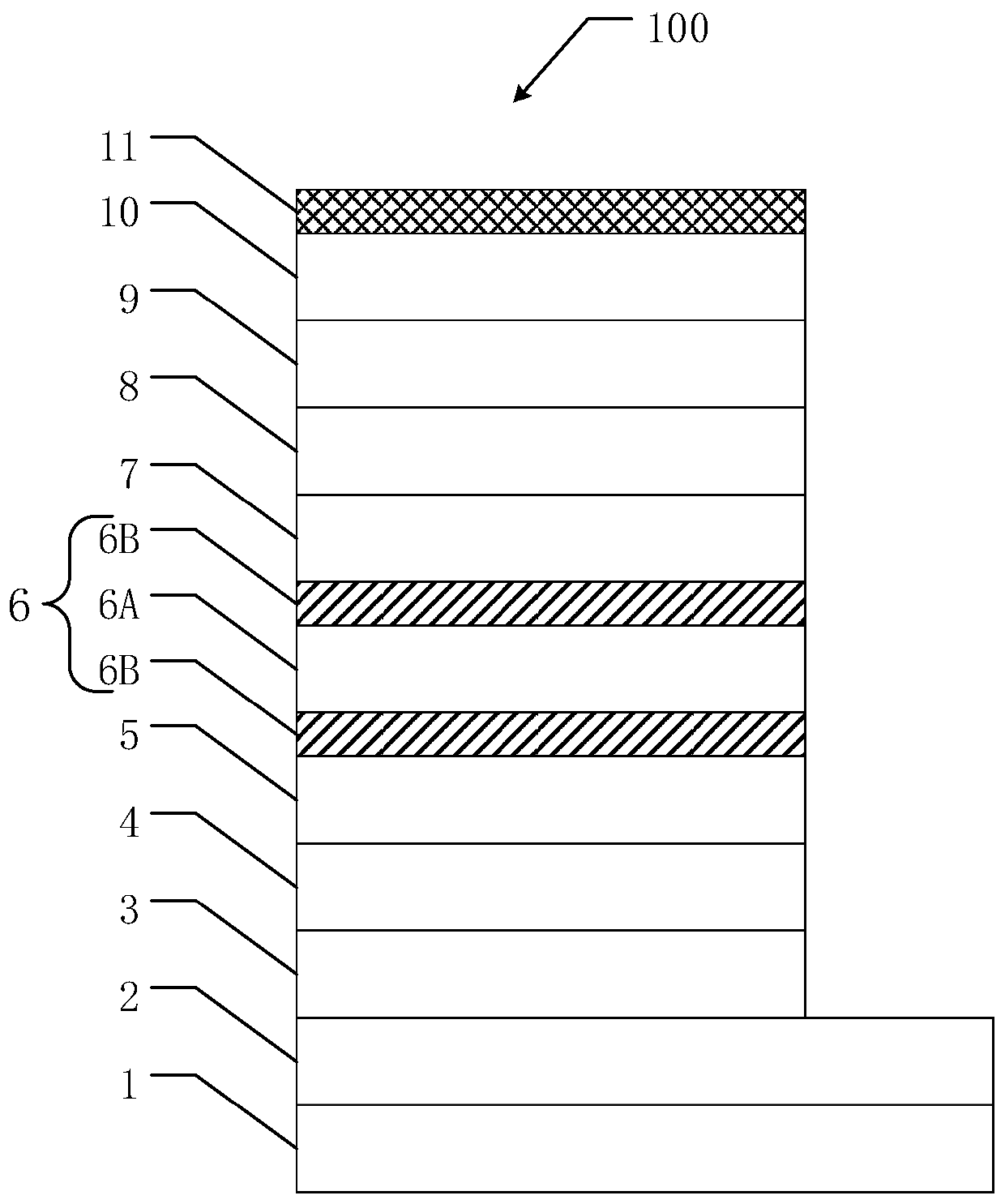

[0065] An organic light emitting diode 100 is disclosed in the embodiment of the present invention, such as image 3 As shown, the organic light emitting diode 100 includes a substrate layer 1, a first electrode layer 2, a hole injection layer 3, a hole transport layer 4, an electron blocking layer 5, a blending active layer 6, a hole blocking layer 7, The electron transport layer 8 , the electron injection layer 9 , the second electrode layer 10 and the second encapsulation layer 11 .

[0066] The material of the substrate layer 1 is polyimide (Polyimide, PI), which is a flexible substrate layer 1, which protects the structure of the organic light emitting diode 100 and enables the organic light emitting diode 100 to realize flexible display.

[0067] The first electrode layer 2 is arranged on the substrate layer 1, and the material of the first electrode layer 2 is indium tin oxide (ITO), which is used to provide a current and voltage for the organic light emitting diode 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com