Full-bean brown fermented soybean milk and preparation method thereof

A technology for fermenting soybean milk and browning, applied in dairy products, milk substitutes, applications, etc., can solve the problems of difficulty in cleaning bean dregs, waste of bean dregs, etc., and achieve the effects of reducing the use of food additives, increasing the browning temperature, and inhibiting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

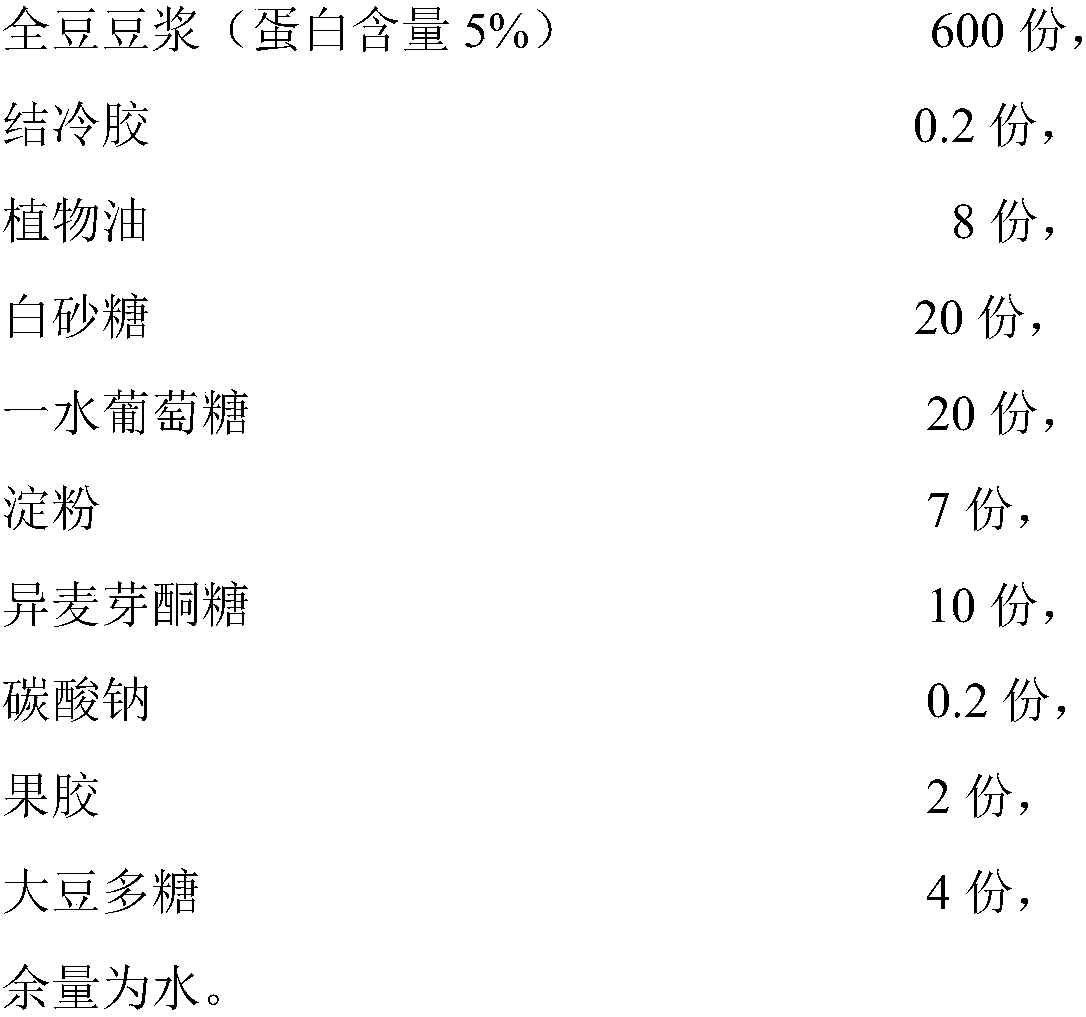

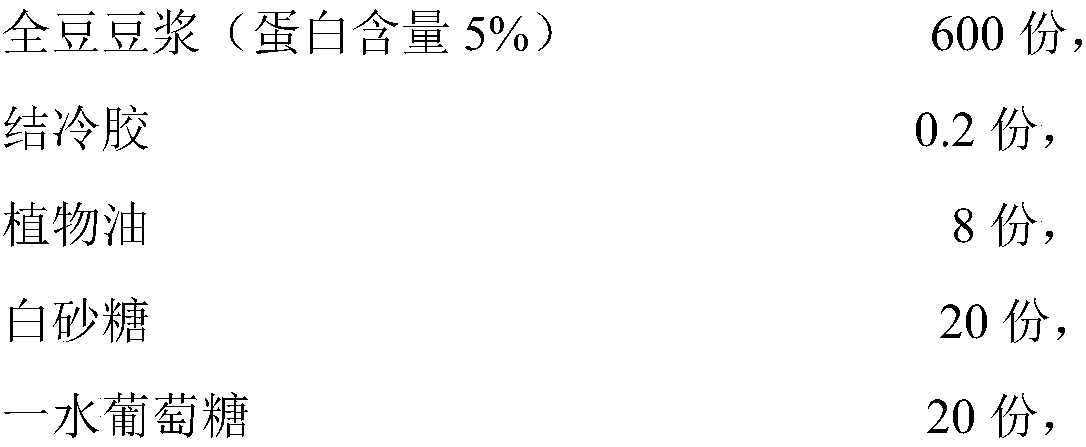

Embodiment 1

[0040] This embodiment provides a whole bean brown fermented soymilk, which is prepared through three processes of soybean roasting, preparation of whole bean soymilk, soymilk blending and browning:

[0041] 1. Soybean baking:

[0042] 1) Soybean peeling:

[0043] S1: Use a fluidized bed to heat soybeans to above 80°C within 120 seconds to make the skin crisp;

[0044] S2: Centrifuge and dehull the soybeans treated in step S1 in the sheller, and then enter the vertical air suction channel to separate the lighter particles from the granular materials;

[0045] S3: Send the soybeans processed in step S2 into the cooling bin, and obtain the soybeans after the first husking after cooling;

[0046] S4: The soybeans after the first husking are milled and dehulled in the sheller, and then the lighter particles and broken beans are separated from the granular materials by using the vibrating screen and the vertical suction channel at the same time, and the granular materials are dis...

Embodiment 2

[0064] This embodiment provides a whole bean brown fermented soymilk, which is prepared through three processes of soybean roasting, preparation of whole bean soymilk, soymilk blending and browning:

[0065] 1. Soybean baking:

[0066] 1) Soybean peeling:

[0067] S1: Use a fluidized bed to heat soybeans to above 80°C within 120 seconds to make the skin crisp;

[0068] S2: In the sheller, the soybeans treated in step S1 are subjected to centrifugal dehulling treatment, and then enter the vertical suction channel to separate lighter particles from the granular materials;

[0069] S3: Send the soybeans processed in step S2 into the cooling bin, and obtain the soybeans after the first husking after cooling;

[0070] S4: The soybeans after the first shelling are milled and dehulled in the sheller, and then the lighter particles and crushed beans are separated from the granular materials by using the vibrating screen and the vertical suction channel at the same time, and the gran...

Embodiment 3

[0089] This embodiment provides a whole bean brown fermented soymilk, which is prepared through three processes of soybean roasting, preparation of whole bean soymilk, soymilk blending and browning:

[0090] 1. Soybean baking:

[0091] 1) Soybean peeling:

[0092] S1: Use a fluidized bed to heat soybeans to above 80°C within 120 seconds to make the skin crisp;

[0093] S2: In the sheller, the soybeans treated in step S1 are subjected to centrifugal dehulling treatment, and then enter the vertical suction channel to separate lighter particles from the granular materials;

[0094] S3: Send the soybeans processed in step S2 into the cooling bin, and obtain the soybeans after the first husking after cooling;

[0095] S4: The soybeans after the first shelling are milled and dehulled in the sheller, and then the lighter particles and crushed beans are separated from the granular materials by using the vibrating screen and the vertical suction channel at the same time, and the gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com