Preparation method and application of adsorbing material for cape jasmine flower essential oil top note extraction

A technology of gardenia essential oil and adsorption material, which is applied in the directions of essential oil/spice, chemical instruments and methods, other chemical processes, etc., to achieve the effects of simple preparation method, excellent adsorption performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

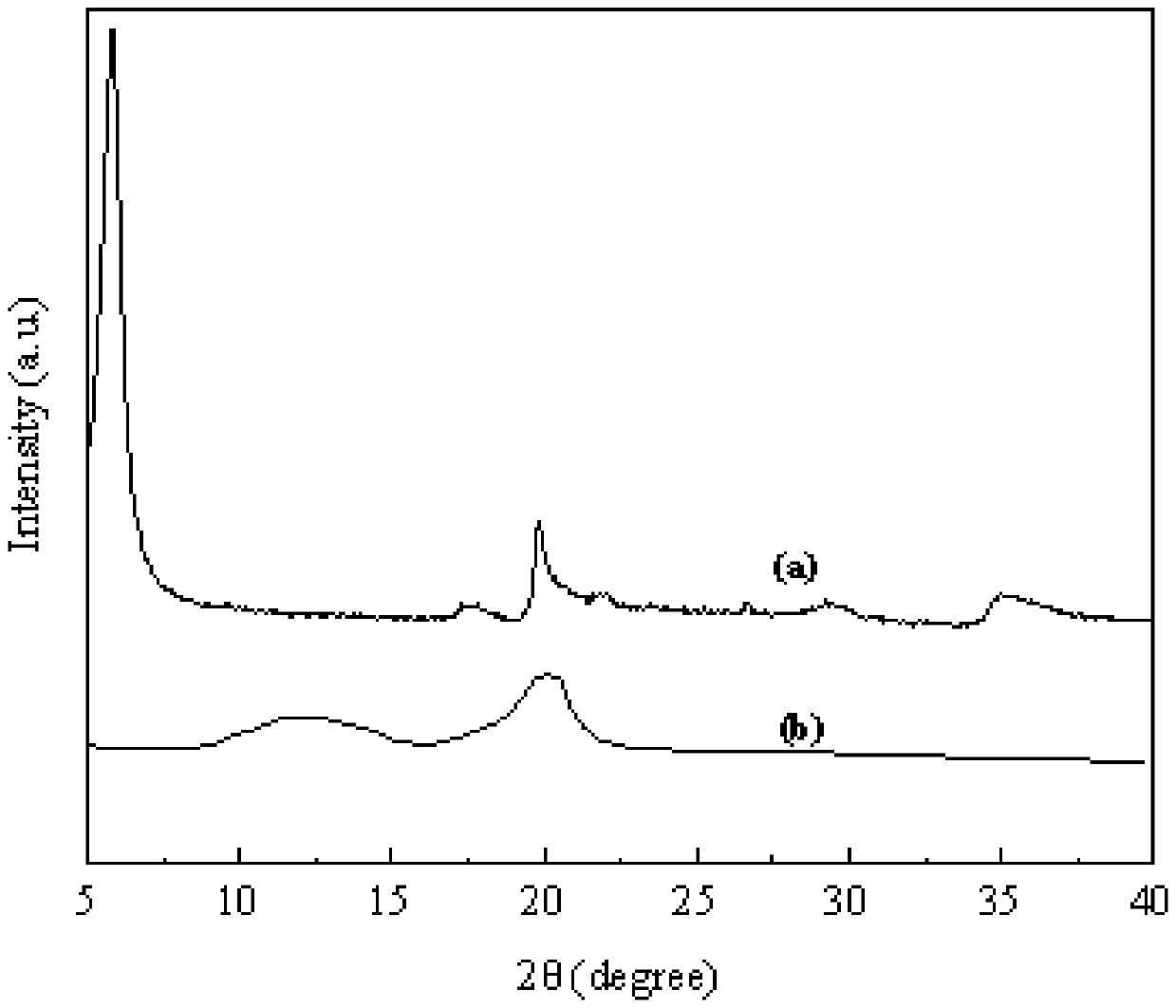

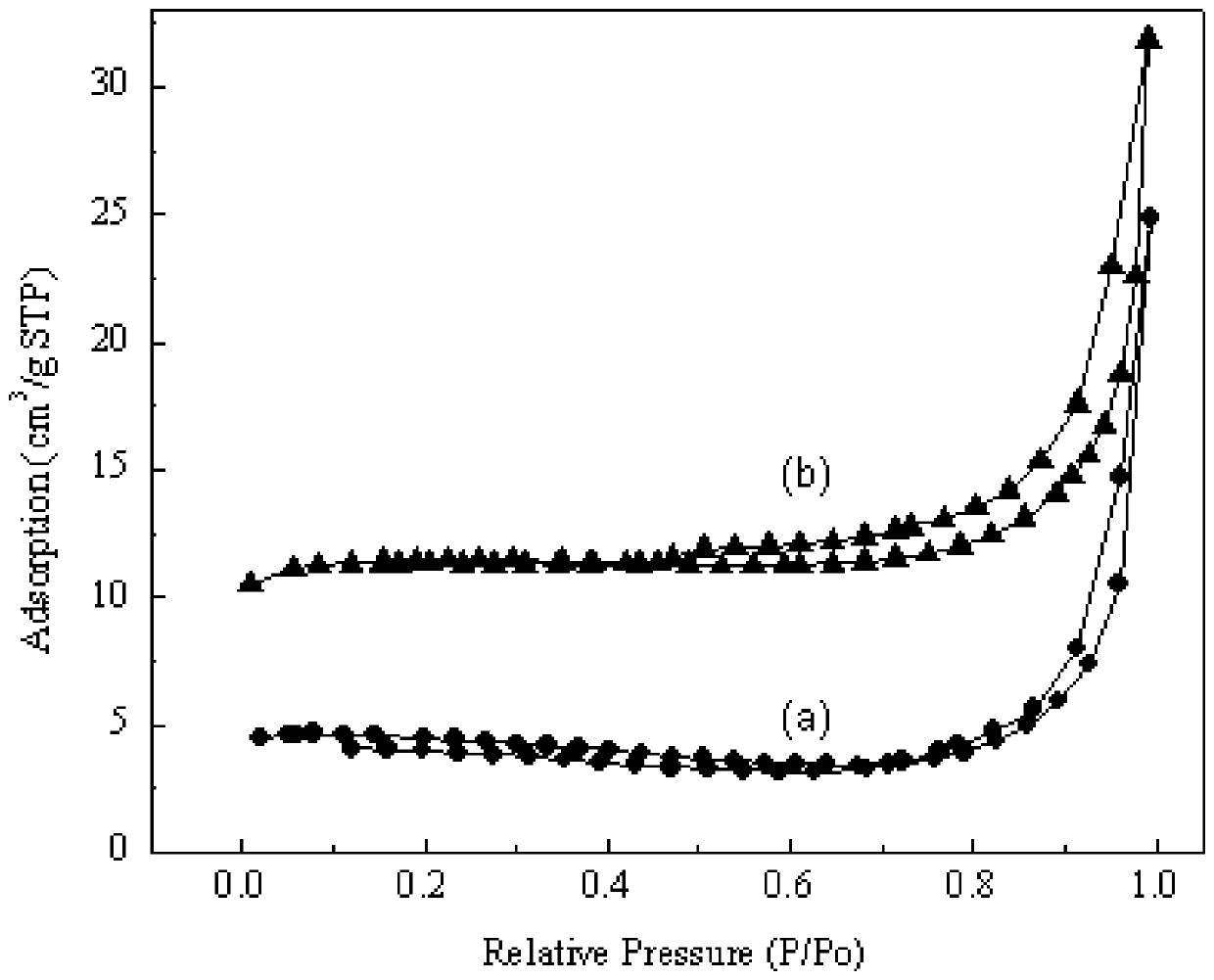

Method used

Image

Examples

Embodiment 1

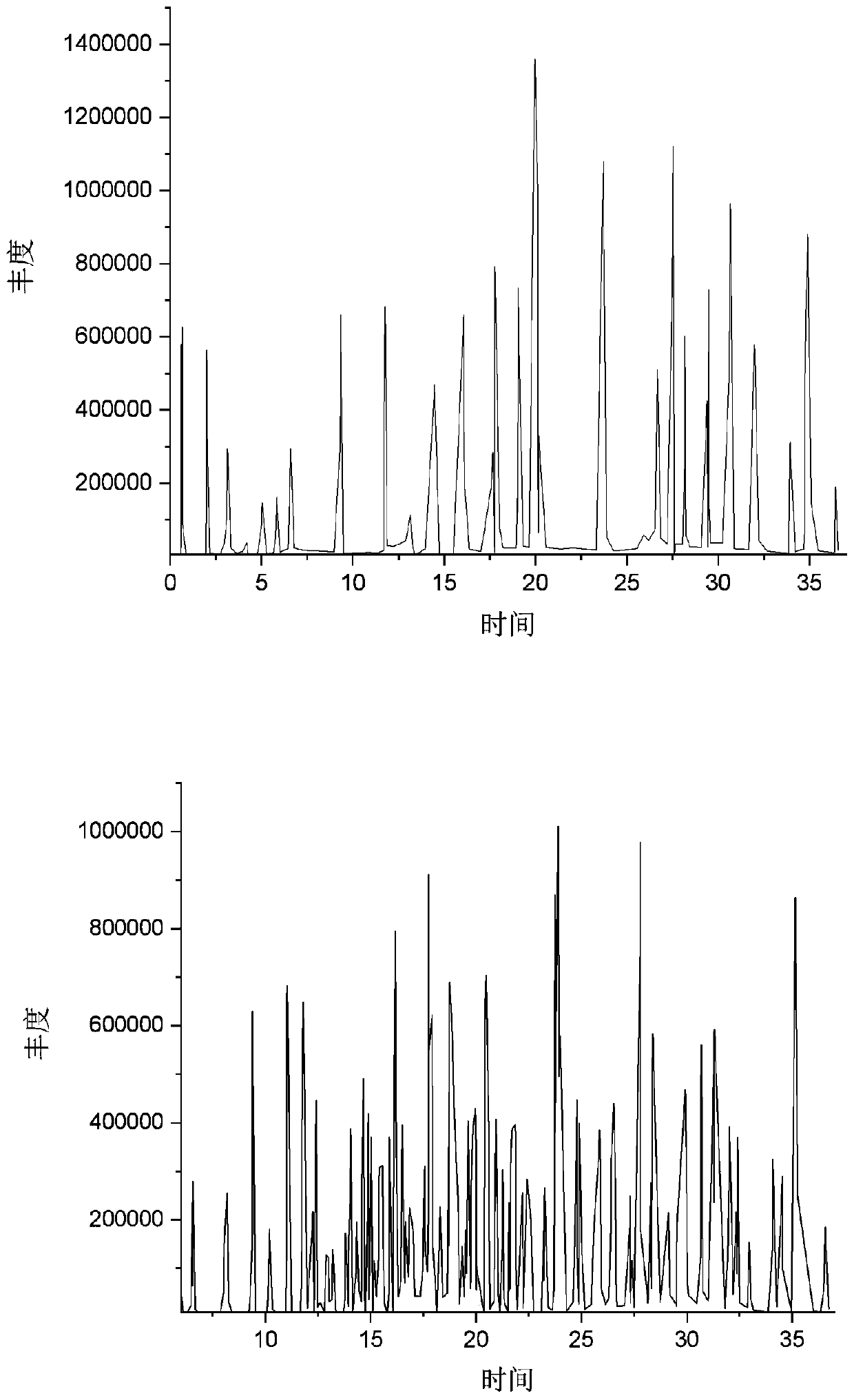

[0032] Weigh 3g of lignin, 5g of montmorillonite and 7ml of deionized water, put them in a reaction kettle, add 0.1mol / L H3PO43ml, stir and react at 200°C, separate and wash with water after fully reacting to obtain biochar / clay composite material. The biochar and montmorillonite composite material were calcined for 3 hours at 400° C. under the protection of nitrogen atmosphere to obtain the lignin biochar and montmorillonite composite material.

[0033] Before use, weigh 30 g of biochar and montmorillonite composite material and desorb at 0.01 MPa for 3 hours. Then the biochar and the montmorillonite composite material were transferred into an oven with 50g of fresh gardenias. Adsorb at room temperature for 10 hours after airtight. Afterwards, the above-mentioned adsorbed biochar and montmorillonite composite material were eluted with absolute ethanol and n-hexane, and the obtained eluate was evaporated with a rotary evaporator until no liquid drops fell down, and gardenia h...

Embodiment 2

[0035] Weigh 3g of lignin, 5g of montmorillonite and 7ml of deionized water, put them in a reaction kettle, add 0.1mol / L H3PO43ml, stir and react at 200°C, separate and wash with water after fully reacting to obtain biochar / clay composite material. The biochar and montmorillonite composite material were calcined for 3 hours at 400° C. under the protection of nitrogen atmosphere to obtain the lignin biochar and montmorillonite composite material.

[0036] Before use, 50 g of biochar and montmorillonite composite were weighed and desorbed at 0.01 MPa for 3 hours. Then the biochar and the montmorillonite composite material were transferred into an oven with 50g of fresh gardenias. Adsorb at room temperature for 10 hours after airtight. Afterwards, the above-mentioned adsorbed biochar and montmorillonite composite material were eluted with absolute ethanol and n-hexane, and the obtained eluate was evaporated with a rotary evaporator until no liquid drops fell down, and gardenia h...

Embodiment 3

[0038] Weigh 3g of lignin, 5g of montmorillonite and 7ml of deionized water, put them in a reaction kettle, add 0.1mol / L H3PO43ml, stir and react at 200°C, separate and wash with water after fully reacting to obtain biochar / clay composite material. The biochar and montmorillonite composite material were calcined for 3 hours at 400° C. under the protection of nitrogen atmosphere to obtain the lignin biochar and montmorillonite composite material.

[0039] Before use, weigh 70g of biochar and montmorillonite composite material and desorb at 0.01MPa for 3 hours. Then the biochar and the montmorillonite composite material were transferred into an oven with 50g of fresh gardenias. Adsorb at room temperature for 10 hours after airtight. Afterwards, the above-mentioned adsorbed biochar and montmorillonite composite material were eluted with absolute ethanol and n-hexane, and the obtained eluate was evaporated with a rotary evaporator until no liquid drops fell down, and gardenia hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com