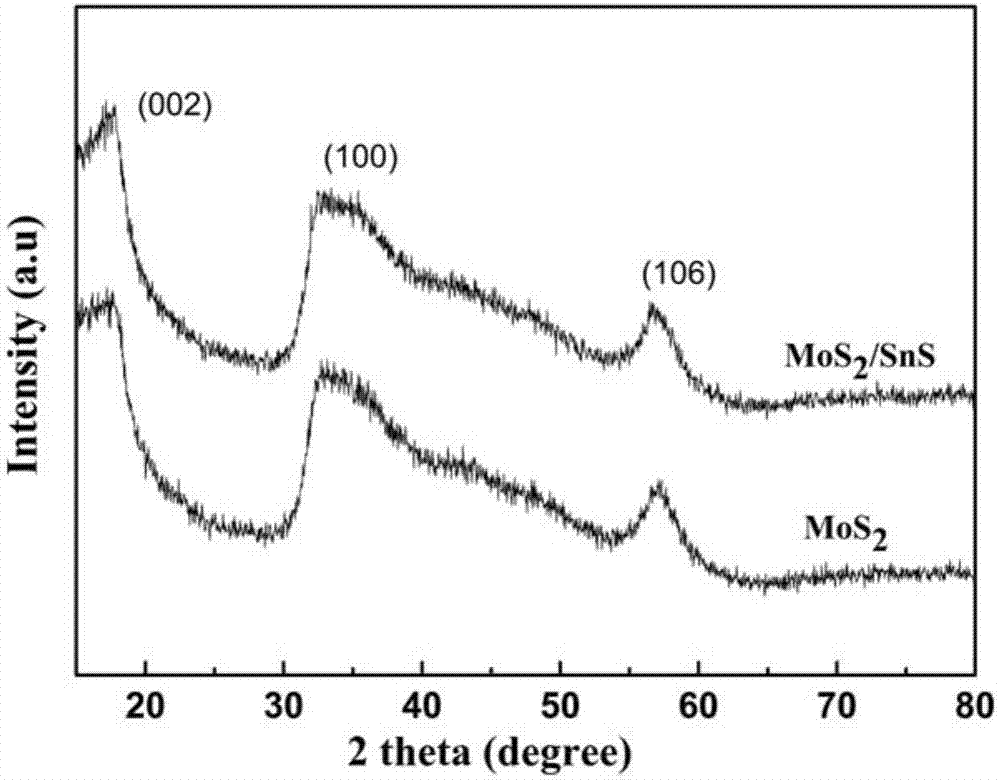

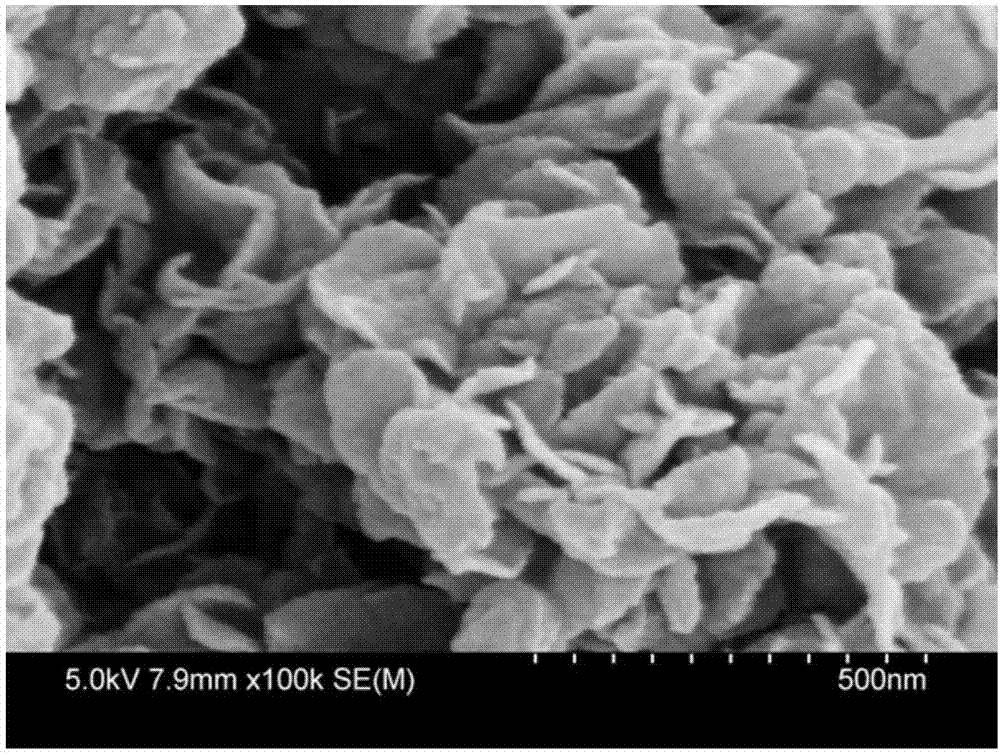

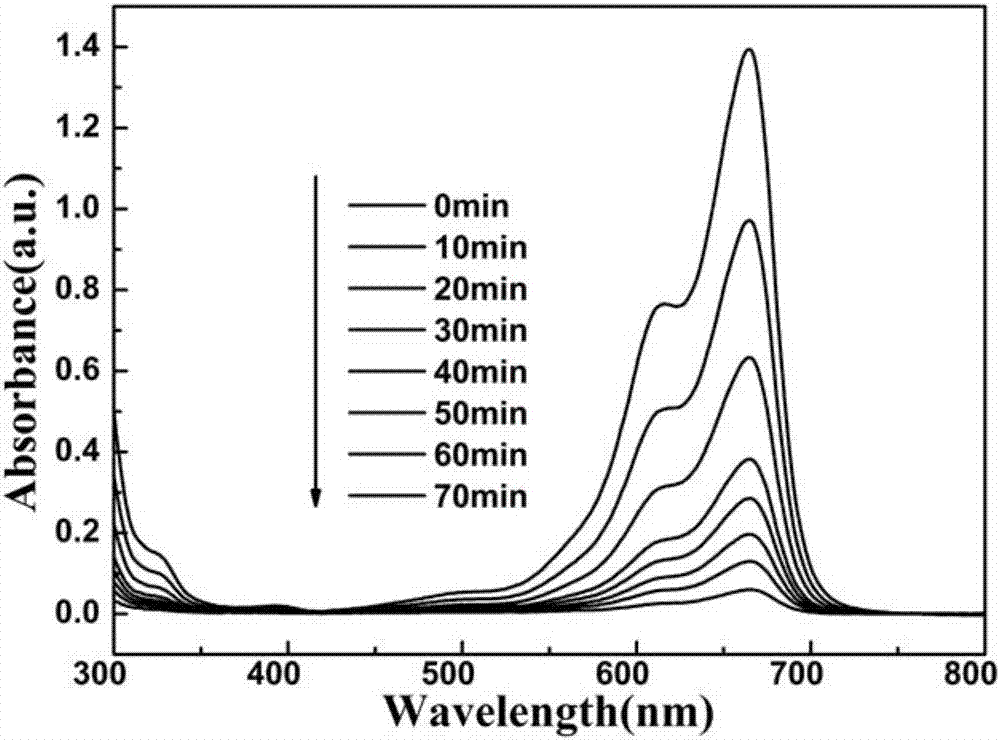

Synthetic method of MoS2/SnS nanometer heterojunction

A synthesis method and heterojunction technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effects of easy operation, simple synthesis process, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Take a certain amount of ammonium molybdate and thiourea and dissolve them in deionized water respectively, and obtain uniform ammonium molybdate solution and thiourea solution after fully stirring and dissolving, wherein Mo in ammonium molybdate solution and thiourea solution 4+ , The concentration of thiourea is 1mol / L, 2mol / L respectively;

[0033] (2) Get a part of ammonium molybdate solution and join in two parts of thiourea solutions with a drop rate of 0.5ml / min, obtain a uniform mixed solution after continuous stirring, Mo in the gained mixed solution 4+ The molar ratio with thiourea is 1:4;

[0034](3) Take a certain amount of lysine and dissolve it in deionized water, pour it into the mixed solution of ammonium molybdate and thiourea after stirring, so that lysine and Mo 4+ The molar ratio is 1:10, and the pH of the solution is adjusted to 4.3 by adding glacial acetic acid with a mass fraction of 99.5%. After fully reacting, the solution obtained is moved...

Embodiment 2

[0042] (1) Take a certain amount of ammonium molybdate and thiourea and dissolve them in deionized water respectively, and obtain uniform ammonium molybdate solution and thiourea solution after fully stirring and dissolving, wherein Mo in ammonium molybdate solution and thiourea solution 4+ , The concentration of thiourea is 1mol / L, 2mol / L respectively;

[0043] (2) Get 1 part of ammonium molybdate solution and join in 2 parts of thiourea solutions at a rate of addition of 0.5ml / min, obtain a uniform mixed solution after continuous stirring, Mo in the gained mixed solution 4+ The molar ratio with thiourea is 1:4;

[0044] (3) Take a certain amount of lysine and dissolve it in deionized water, pour it into the mixed solution of ammonium molybdate and thiourea after stirring, so that lysine and Mo 4+ The molar ratio is 1:10, and the pH of the solution is adjusted to 4.6 by adding glacial acetic acid with a mass fraction of 99.5%. After fully reacting, the solution obtained is m...

Embodiment 3

[0050] (1) Take a certain amount of ammonium molybdate and thiourea and dissolve them in deionized water respectively, and obtain uniform ammonium molybdate solution and thiourea solution after fully stirring and dissolving, wherein Mo in ammonium molybdate solution and thiourea solution 4+ , The concentration of thiourea is 1mol / L, 2mol / L respectively;

[0051] (2) Get 1 part of ammonium molybdate solution and join in 2 parts of thiourea solutions at a rate of addition of 0.5ml / min, obtain a uniform mixed solution after continuous stirring, Mo in the gained mixed solution 4+ The molar ratio with thiourea is 1:4;

[0052] (3) Take a certain amount of lysine and dissolve it in deionized water, pour it into the mixed solution of ammonium molybdate and thiourea after stirring, so that lysine and Mo 4+ The molar ratio is 1:10, and the pH of the solution is adjusted to 4.8 by adding glacial acetic acid with a mass fraction of 99.5%. After fully reacting, the solution obtained is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com