Waterproof gypsum board core, preparation method thereof and waterproof gypsum board

A gypsum board and board core technology, which is applied in the field of gypsum board materials, can solve the problems of reduced adhesive force of gypsum board, reduction of gypsum board's own advantages, changes in strength and weight of gypsum board, and achieve the effect of improving hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

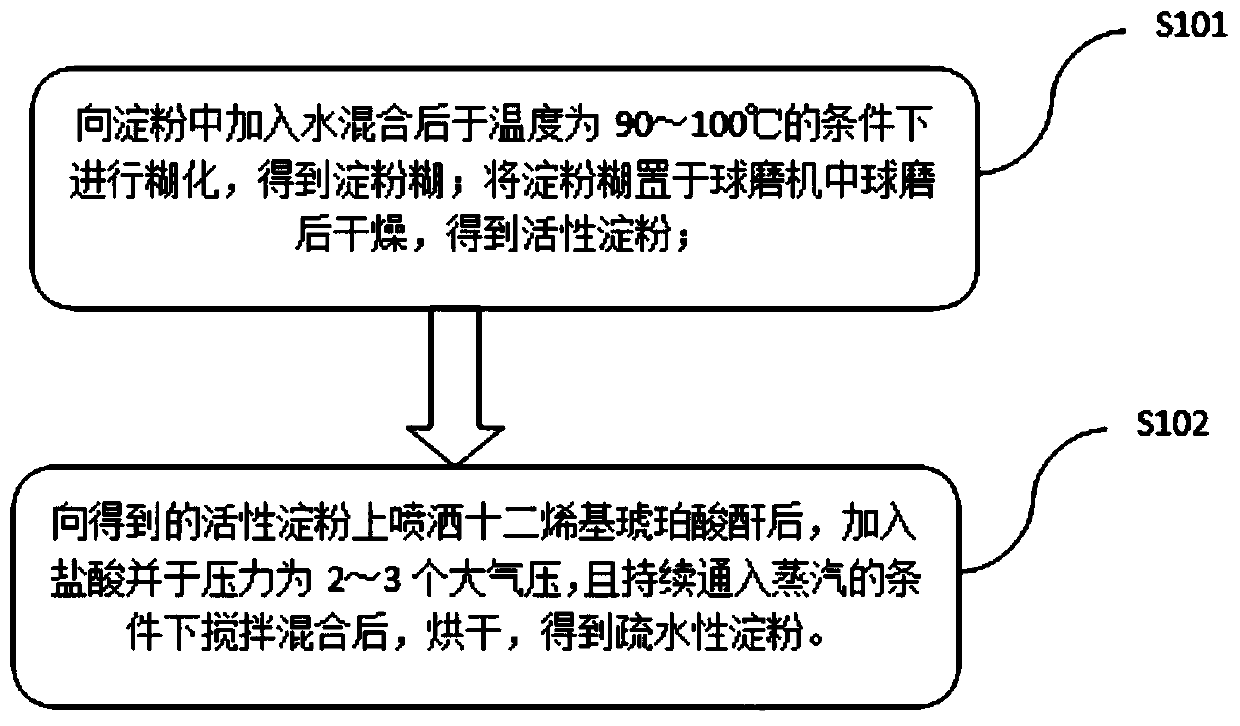

[0051] S101. Preparation of active starch: add water to the starch and mix, then gelatinize at a temperature of 90-100°C to obtain starch paste; put the starch paste in a ball mill and dry to obtain active starch;

[0052] S102. Preparation of hydrophobic starch: after spraying dodecenyl succinic anhydride on the obtained active starch, adding hydrochloric acid, stirring and mixing at a pressure of 2 to 3 atmospheres, and continuously feeding steam, drying, Obtain hydrophobic starch. The specific preparation flow chart is as figure 2 shown. The contact area between the dodecenyl succinic anhydride and the active starch is increased by spraying the dodecenyl succinic anhydride on the activated active starch, and the grafting efficiency is improved. At the same time, the use of dodecenyl succinic anhydride can increase the length of the long chain after grafting, and more effectively improve the formation of the needle-like structure in the later stage.

[0053] In a further...

Embodiment 1

[0074] Stir and mix 100 parts by weight of plaster powder, 30 parts by weight of water, hydrophilic starch and 0.05 parts by weight of glass fiber to obtain a prefabricated slurry;

[0075] Add 0.07 parts by weight of foaming agent, 0.5 parts by weight of coagulation accelerator, hydrophobic starch and 45 parts by weight of water to the obtained prefabricated slurry, stir and mix them, and then mold them to obtain waterproof gypsum board core A1. (wherein, the total amount of hydrophilic starch and hydrophobic starch is 0.1 parts by weight, and the weight ratio of hydrophobic starch and hydrophilic starch is 1:0.8)

Embodiment 2

[0077] Stir and mix 100 parts by weight of Paris plaster, 40 parts by weight of water, hydrophilic starch and 0.15 parts by weight of glass fiber to obtain a prefabricated slurry;

[0078] Add 0.15 parts by weight of foaming agent, 2 parts by weight of coagulation accelerator, hydrophobic starch and 45 parts by weight of water to the obtained prefabricated slurry, stir and mix them, and then mold them to obtain waterproof gypsum board core A2. (wherein the total amount of hydrophilic starch and hydrophobic starch is 4 parts by weight, and the weight ratio of hydrophobic starch and hydrophilic starch is 1:1.2)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com