A kind of temperature-sensitive phosphor and its preparation method and application

A fluorescent powder and temperature-sensitive technology, applied in the field of fluorescent powder, can solve the problems of narrow temperature measurement range, low temperature measurement accuracy, and large temperature measurement range, achieving wide temperature measurement range, high temperature measurement accuracy, The effect of wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A Sr(Pr x Lu 1-x ) 2 O 4 (x=0.001) The preparation method of the phosphor is as follows:

[0060] 1. Take SrCO 3 , Lu 2 O 3 and Pr 6 O 11 As the initial raw material, the molar ratio of Sr:Pr:Lu is 1:0.002:1.998 for batching, and each raw material is ball-milled for 5 h to obtain a mixed powder with an average particle size of 0.5-5 μm;

[0061] 2. Press the mixed powder into a block at 40 MPa, put it into a platinum crucible, sinter it in the air at 1100°C for 10 hours, drop it to room temperature, and grind it to obtain a primary sintered powder with an average particle size of 0.5-15 μm. ;

[0062] 3. Press the initially fired powder into a block at 40 MPa, put it in a platinum crucible, sinter at 1600 °C for 6 h in a CO / Ar (volume ratio of 5:95) reducing atmosphere, and then drop to room temperature for grinding. get the final SrLu 2 O 4 : Pr (x=0.1 at.%) phosphor with an average particle size of 0.5-15μm.

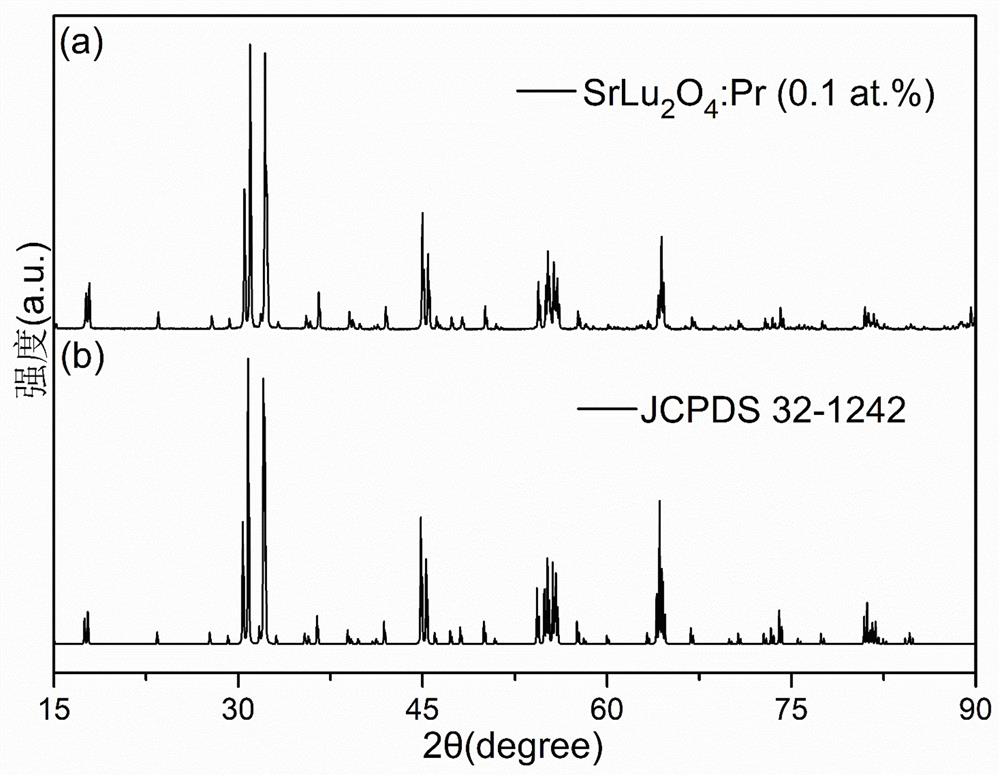

[0063] The XRD pattern of the obtained phosph...

Embodiment 2

[0065] A Sr(Pr x Gd 1-x ) 2 O 4 (x=0.001) The preparation method of the phosphor is as follows:

[0066] 1. Take SrCO 3 , Gd 2 O 3 and Pr 6 O 11 As the initial raw material, the molar ratio of Sr:Pr:Gd is 1:0.002:1.998, and the ingredients are mixed with alcohol solution for 1 h. After drying in a fume hood at room temperature, grinding to obtain an average particle size of 0.5- 5 μm mixed powder;

[0067] 2. Press the mixed powder into a block at 40 MPa, put it in a corundum crucible, sinter it in the air at 1100 °C for 10 hours, then lower it to room temperature, and grind it to obtain a primary sintered powder with an average particle size of 0.5-15 μm. ;

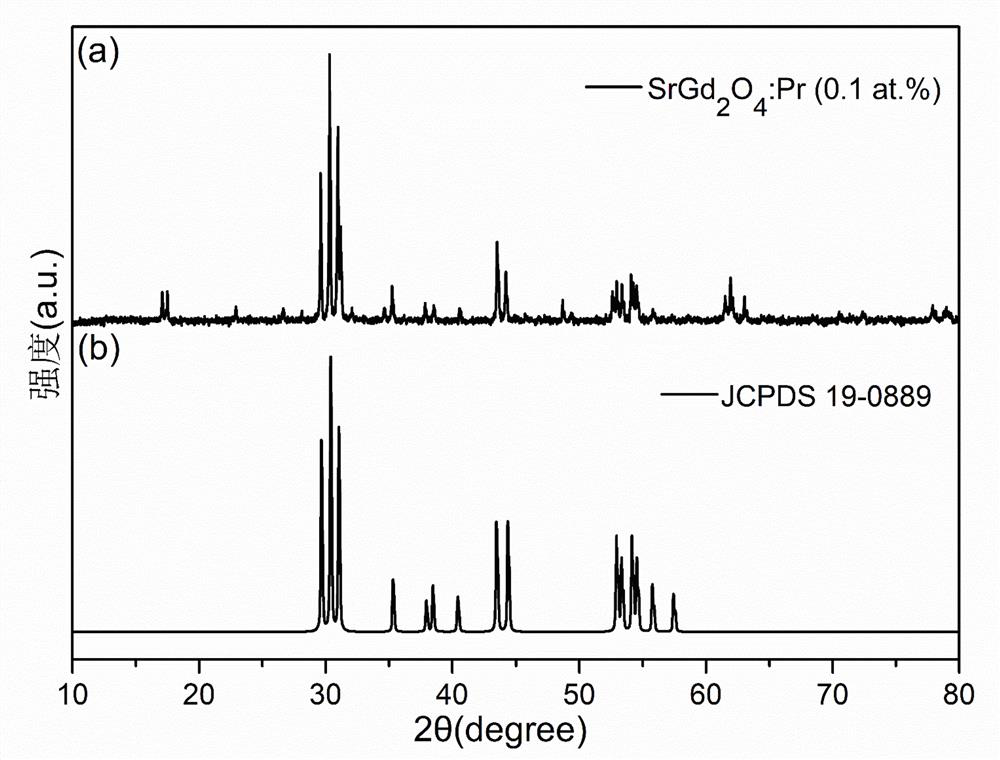

[0068] 3. Press the initially fired powder into a block at 40 MPa, put it into a corundum crucible, and put it in a corundum crucible. 2 / Ar (volume ratio of 5:95) was sintered at 1550 °C for 5 h in a reducing atmosphere, cooled to room temperature, and ground to obtain the final SrGd 2 O 4: Pr (x=0.1 at.%) ...

Embodiment 3

[0072] A Sr(Pr x Y 1-x ) 2 O 4 (x=0.001) The preparation method of the phosphor is as follows:

[0073] 1. Take SrCO 3 , Y 2 O 3 and Pr 6 O 11 As the initial raw material, according to the molar ratio of Sr:Pr:Y is 1:0.002:1.998, the ingredients are mixed, and each raw material is wet-mixed with an alcohol solution for 1 h, dried at room temperature in a fume hood, and ground to obtain an average particle size of 0.5- 5 μm mixed powder;

[0074] 2. Press the mixed powder into a block at 40 MPa, put it into a corundum crucible, sinter it in the air at 1100 °C for 10 hours, lower it to room temperature, and grind it to obtain a primary sintered powder with an average particle size of 0.5-15 μm;

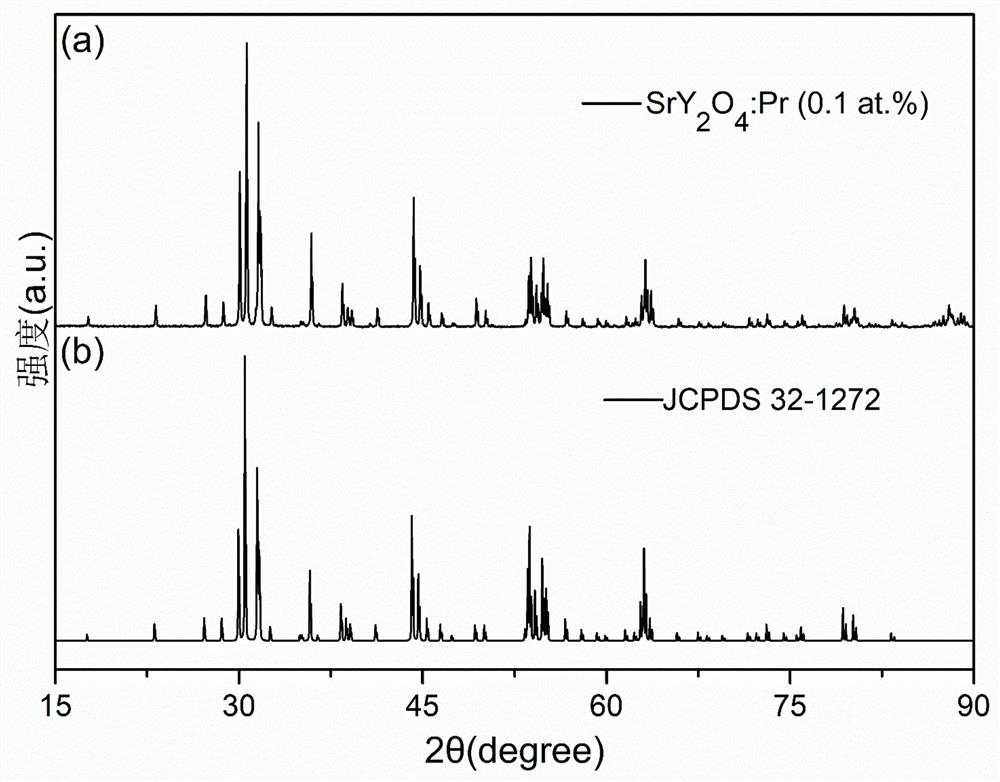

[0075] 3. Press the initially fired powder into a block at 40 MPa, put it into a corundum crucible, and put it in a corundum crucible under H 2 / Ar (volume ratio of 5:95) was sintered at 1550 °C for 5 h in a reducing atmosphere, cooled to room temperature, and ground to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com