Method and device for preparing array droplet crystals

A preparation device and array technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of short production cycle, uncontrollable product quality, slow reaction speed and other problems in the production process, and achieve high yield , Ensuring effectiveness and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

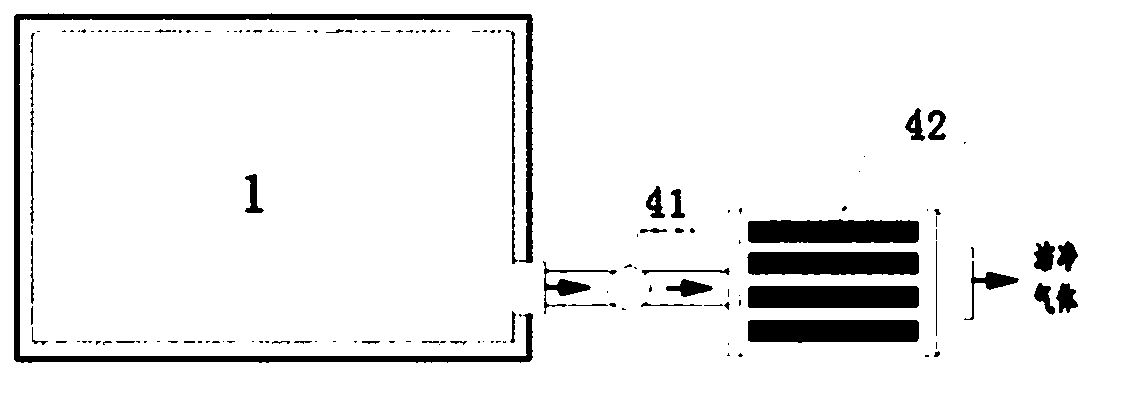

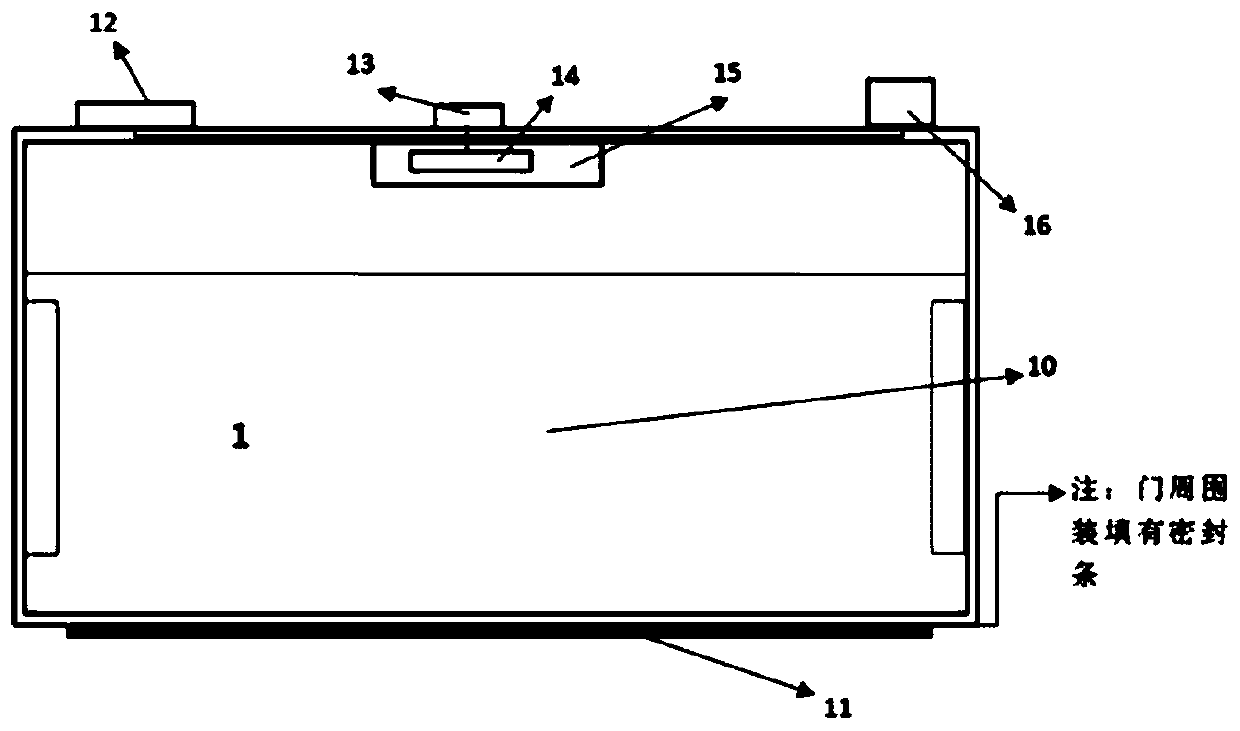

[0037] Such as figure 1 As shown, the array type droplet crystal preparation device of the present invention includes an operation box 1 and a solvent absorption device 4. The solvent absorption device includes a cylinder 42 and an air suction pump 41 connected to the cylinder. The cylinder is filled with solid absorption agent (such as: activated carbon), the cylinder body communicates with the cavity in the operation box through pipelines, and when the suction pump 41 works, the air in the operation box is sucked into the cylinder body for adsorption treatment.

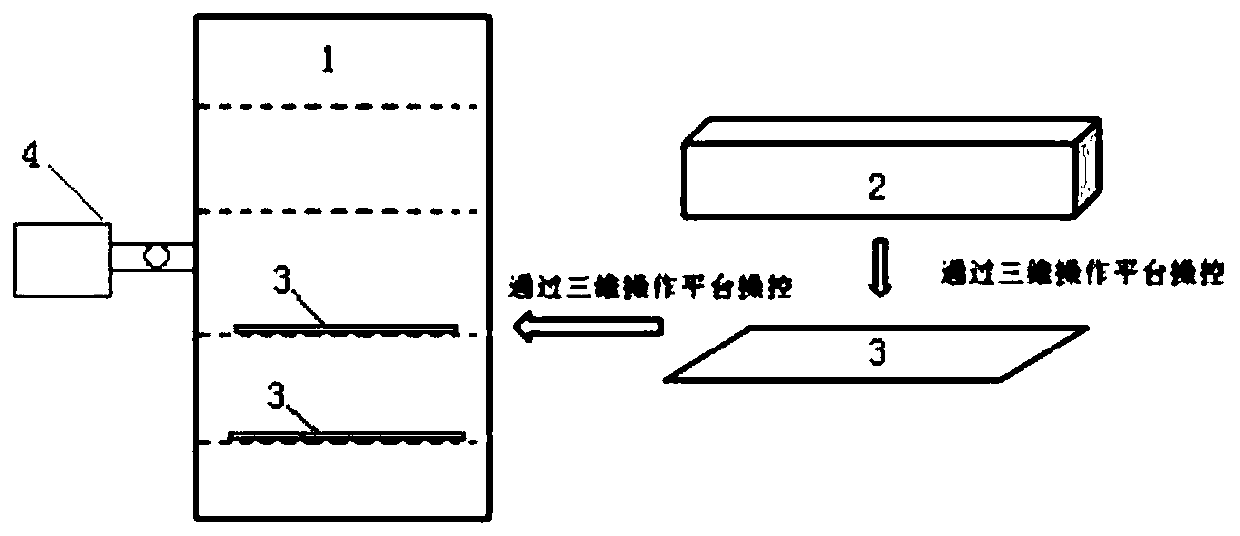

[0038] The array droplet crystal preparation device also includes an array droplet preparation module 2 and a crystal growth substrate module 3 .

[0039] Such as Figure 4 As shown, the array droplet preparation module 2 includes a number of droplet tubes with the same structure arranged in an array, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com