High-concentration non-precipitation concentrated tea liquor production system and production technology applying same

A production system, technology without sedimentation, applied in the field of concentrated tea juice, can solve the problem of poor sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

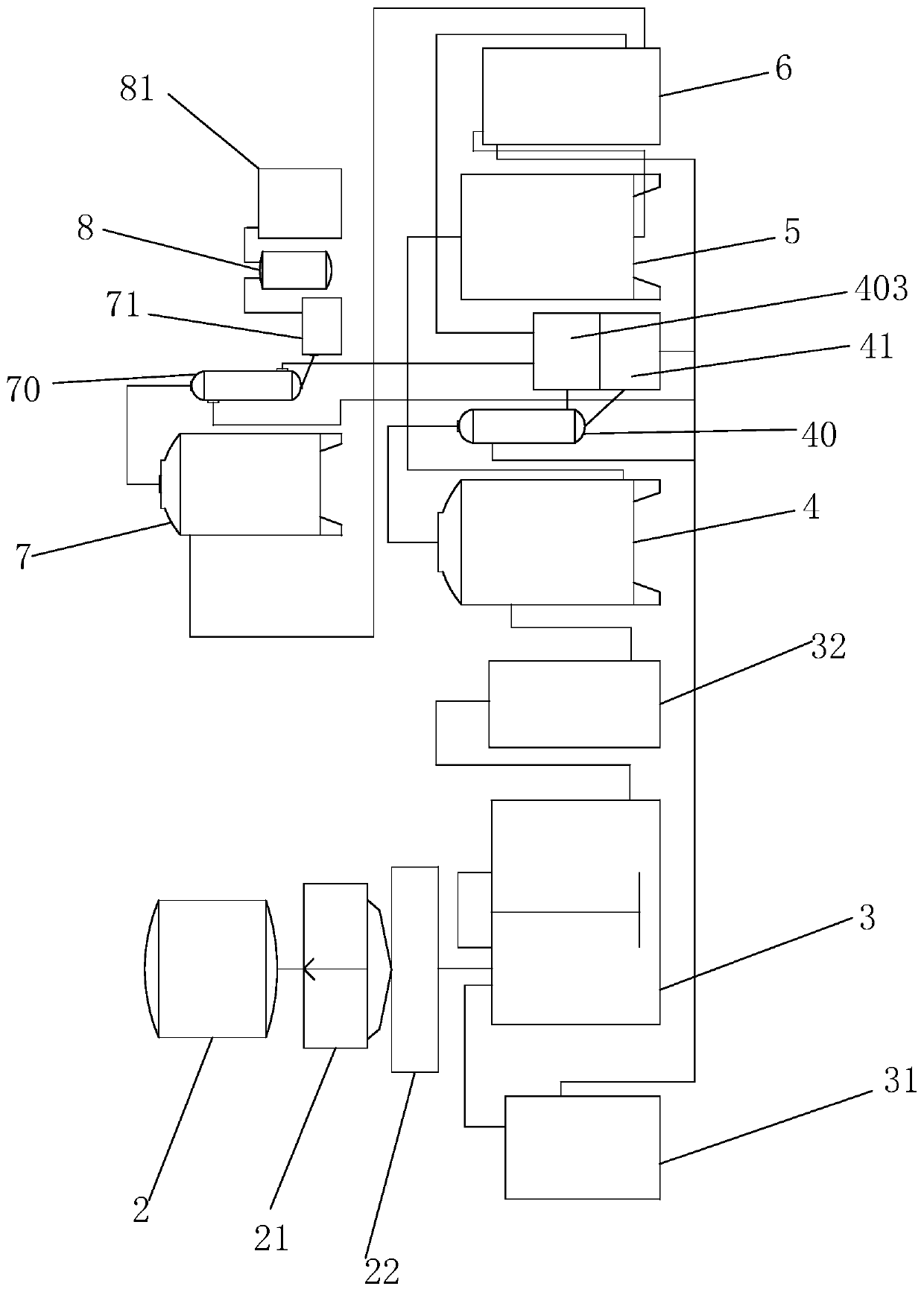

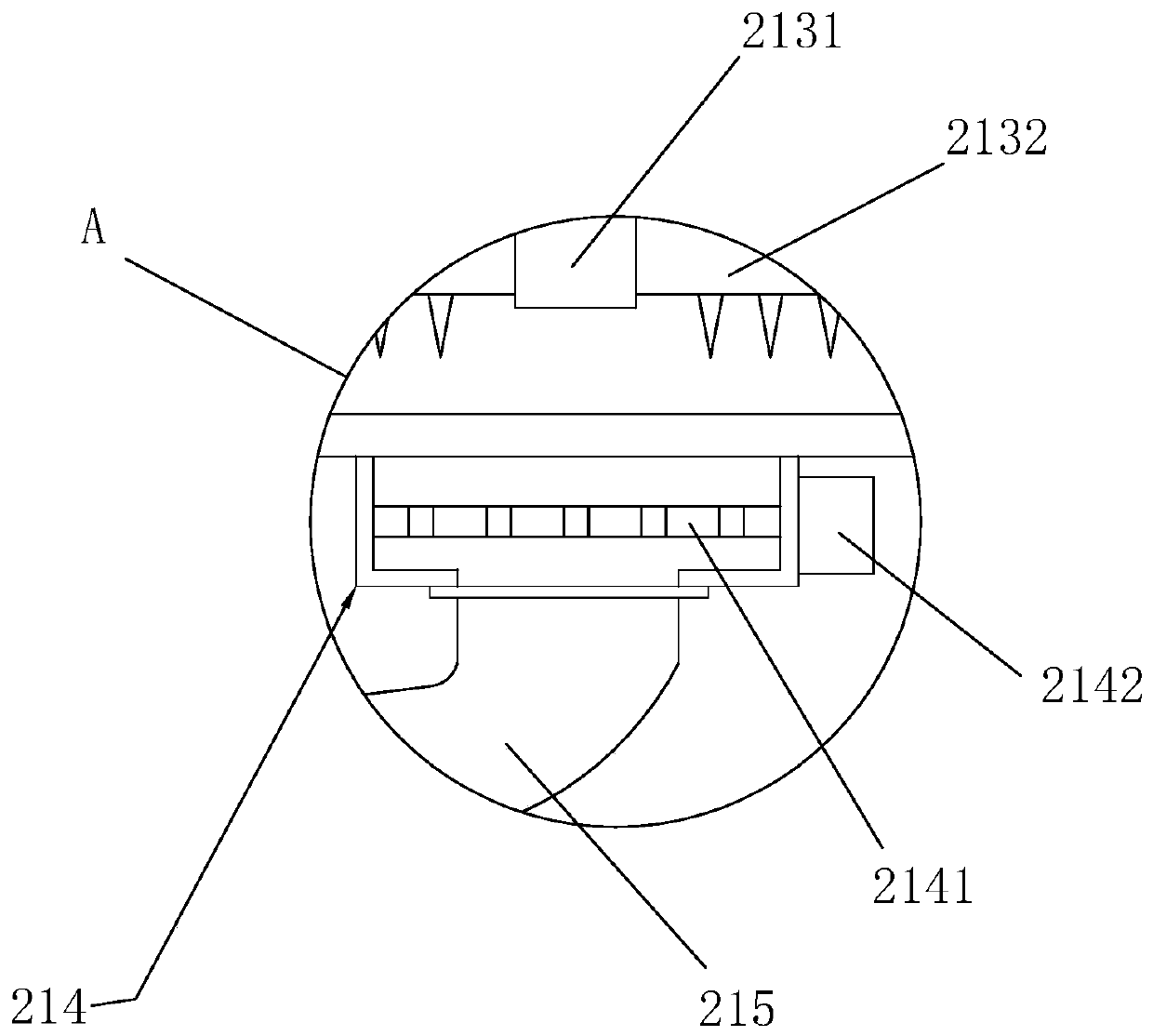

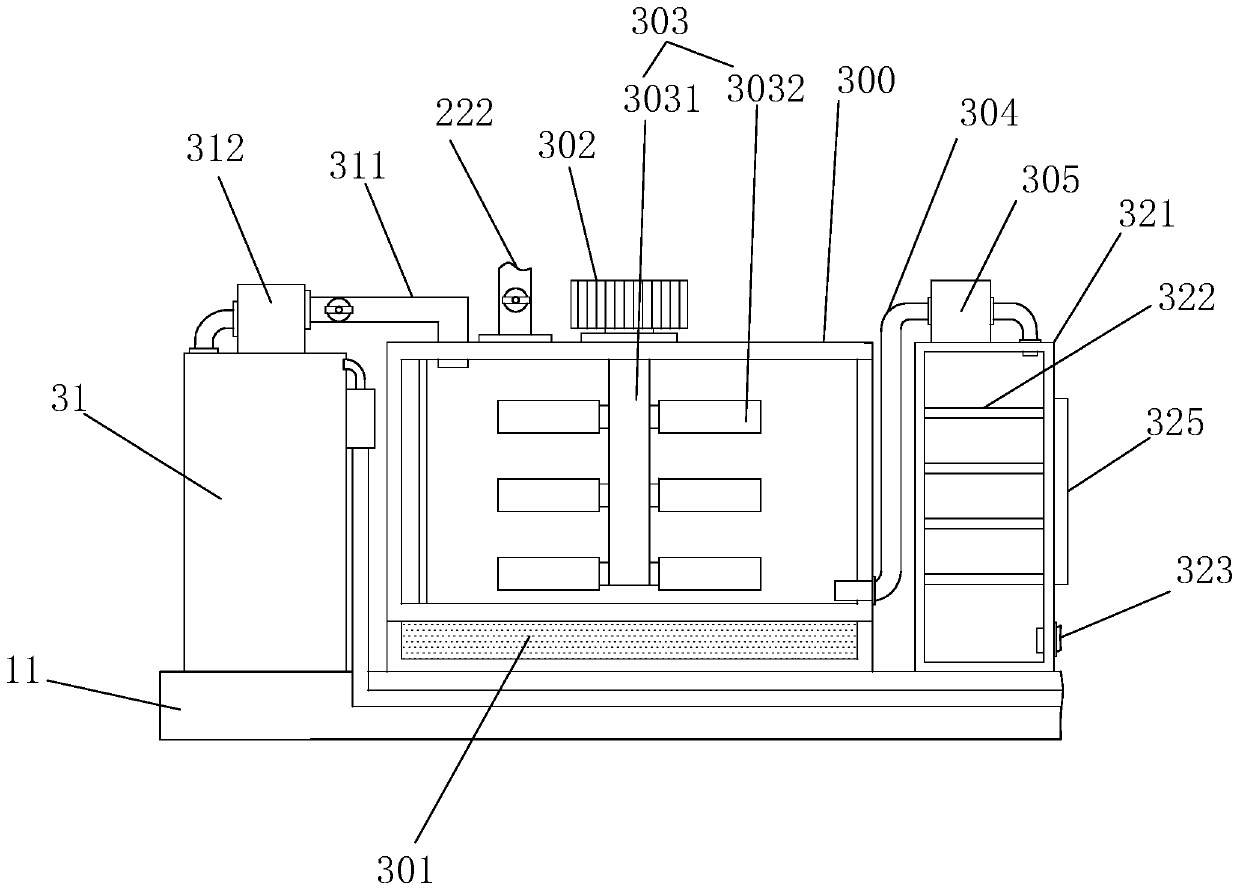

[0049] refer to figure 1 , which is a high-concentration non-precipitation concentrated tea juice production system disclosed in the present invention and its production process, including an equipment installation bracket 1, and the equipment installation bracket 1 is formed with a bottom layer 11 from bottom to top (identified image 3 ), the second support layer 12 (logo figure 2 ) and a third support layer 13 (identifying the figure 2 ); the third supporting layer 13 is fixedly connected with a drying device 2; the second supporting layer 12 is equipped with a high-speed dispersion device 21 that communicates with the drying device 2 and is located below the drying device 2, and the high-speed dispersion device 21 is used for drying The tea leaves are dispersed and crushed into tea powder; the second support layer 12 is equipped with a tea powder storage box 22 connected to the high-speed dispersion device 21 and located below the high-speed dispersion device 21, and th...

Embodiment 2

[0059] Embodiment two: the process of producing high-concentration non-precipitating concentrated tea juice using a high-concentration non-precipitating concentrated tea juice production system:

[0060] refer to Figure 8 , Step 1: Put the tea into the drying tank 200, turn on the first driving motor 201, the first heater 2081 and the cooling fan 2082, and fully dry the tea leaves in the drying tank 200;

[0061] Step 2: Transfer the dried tea leaves in step 2 to the high-speed dispersion box 211, turn on the second drive motor 213 to disperse and crush the dried tea leaves to obtain tea powder, which is stored in the tea powder storage Reserve in case 22;

[0062] Step 3: In Step 2, the tea powder in the tea powder storage tank 22 is added into the boiling tank 300, and at the same time, the water in the pure water tank 31 is added to the boiling tank 300 under the action of the first centrifugal pump 312, and the tea powder is The quality and water body mass ratio are 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com