Waste spinning regenerated composite fiberboard and preparation method and application thereof

A composite fiber and fiberboard technology, which is applied in the field of waste spinning and regenerated composite fiberboard and its preparation, can solve the problems of high preparation cost, low utilization rate of waste textiles, and high requirements for raw materials of recycled fiberboard, so as to reduce production costs, reduce workload, and solve the The effect of low recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

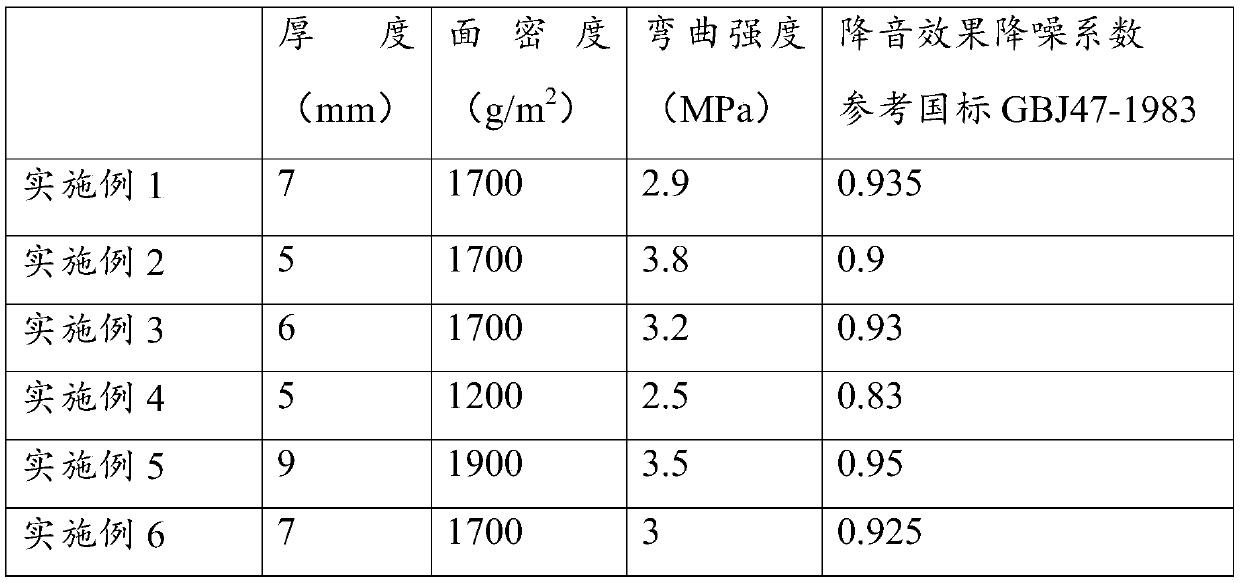

Examples

preparation example Construction

[0033] A preparation method of waste spinning regenerated composite fiberboard, comprising the steps of:

[0034] Waste textiles are opened to obtain waste spinning fibers, and waste spinning fibers include waste spinning chemical fibers;

[0035] (a) sequentially carding, laying, needling and shaping the low-melting fiber and waste spinning chemical fiber to obtain the first fiberboard;

[0036] (b) Air-laid, bonded and shaped the low-melting fiber and waste spun fiber in sequence to obtain a second fiberboard;

[0037] (c) The first fiberboard and the second fiberboard are hot-press bonded or needle-punched to obtain a waste spinning regenerated composite fiberboard;

[0038] The melting point of the low melting point fiber is 130-170°C.

[0039] The preparation method of the waste spinning regenerated composite fiberboard provided by the present invention combines the two non-woven processes of carding and air laying, and prepares the first fiberboard from waste spinning ...

Embodiment 1

[0053] A preparation method of waste spinning regenerated composite fiberboard, comprising the steps of:

[0054] (a) sequentially carding, laying, needling and shaping the low-melting fiber and waste spinning chemical fiber to obtain the first fiberboard;

[0055] The low-melting point fiber is 4080 fiber, the content is 40w / w%, and the content of waste spinning chemical fiber is 60w / w%. 1200g / ㎡, base fiberboard with a thickness of 8mm.

[0056] (b) Air-laid, bonded and shaped the low-melting fiber and waste spun fiber in sequence to obtain a second fiberboard;

[0057] The low melting point fiber is 4080 fiber, the content is 45w / w%, and the content of waste spinning fiber is 55w / w%. After air-laid, it is formed by thermal bonding, and then it is shaped by cold rolling. ㎡, surface fiberboard with a thickness of 2mm.

[0058] (c) The first fiberboard and the second fiberboard are bonded by heat and pressure to obtain a waste spinning regenerated composite fiberboard;

[0...

Embodiment 2

[0061] A preparation method of waste spinning regenerated composite fiberboard, comprising the steps of:

[0062] (a) sequentially carding, laying, needling and shaping the low-melting fiber and waste spinning chemical fiber to obtain the first fiberboard;

[0063] The low-melting point fiber is 4080 fiber with a content of 50w / w%, and the content of waste spinning chemical fiber is 50w / w%. After carding and laying the net, it undergoes pre-acupuncture and main acupuncture in sequence, and then uses hot rolling to set the shape to obtain the first fiberboard .

[0064] (b) Air-laid, bonded and shaped the low-melting fiber and waste spun fiber in sequence to obtain a second fiberboard;

[0065] The low melting point fiber is 4080 fiber, the content is 35w / w%, and the waste spinning fiber content is 65w / w%. After air-laid, it is formed by thermal bonding, and then it is shaped by cold rolling. Fiberboard.

[0066] (c) The first fiberboard and the second fiberboard are bonded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com