Polycarboxylate water reducer

A technology of water reducer and polycarboxylate, which is applied in the field of polycarboxylate water reducer, can solve the problems of low conversion rate of raw materials, influence of water reducer performance, cumbersome production process, etc., and achieve good batch stability, concrete and Good workability and uniform molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

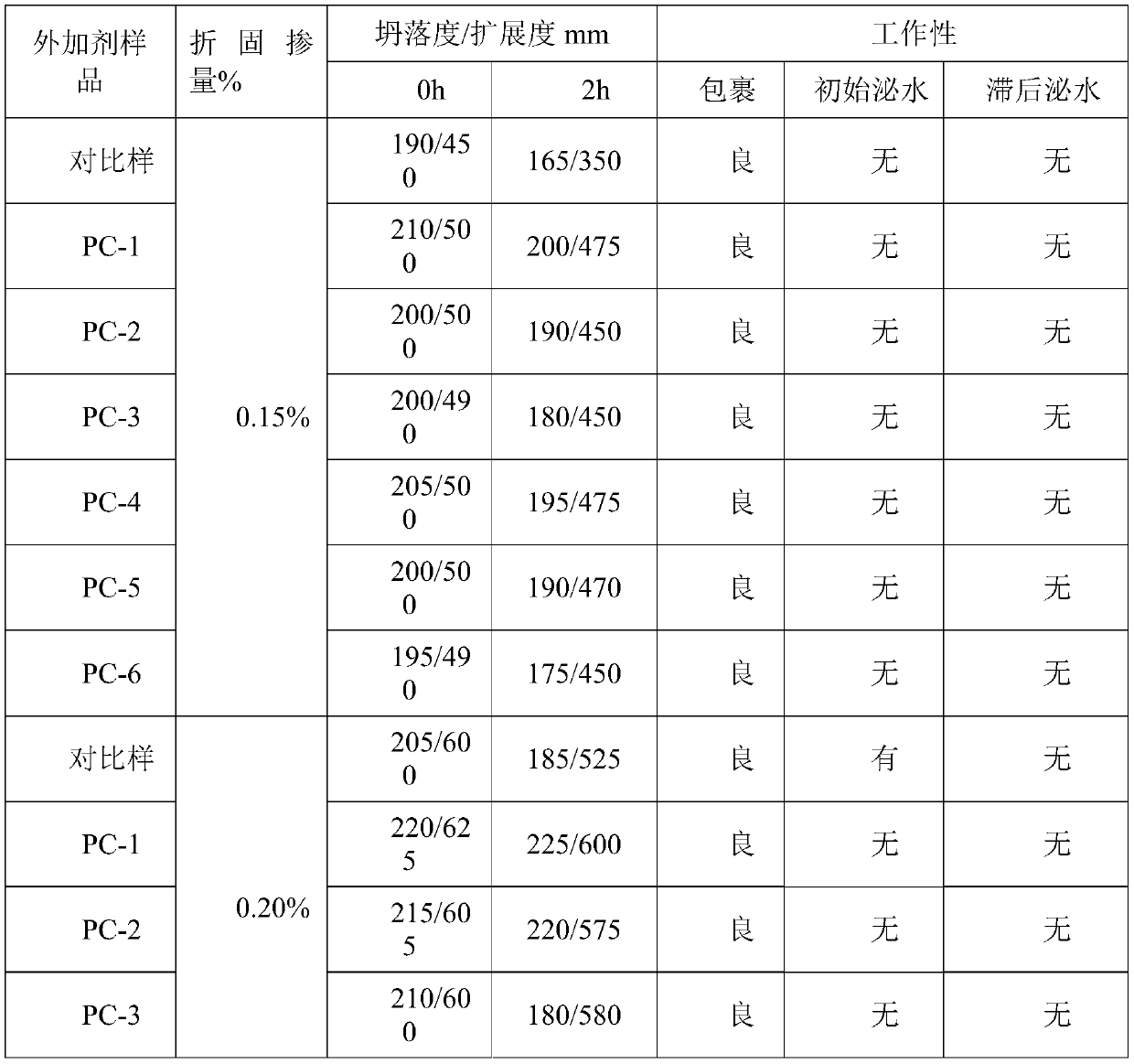

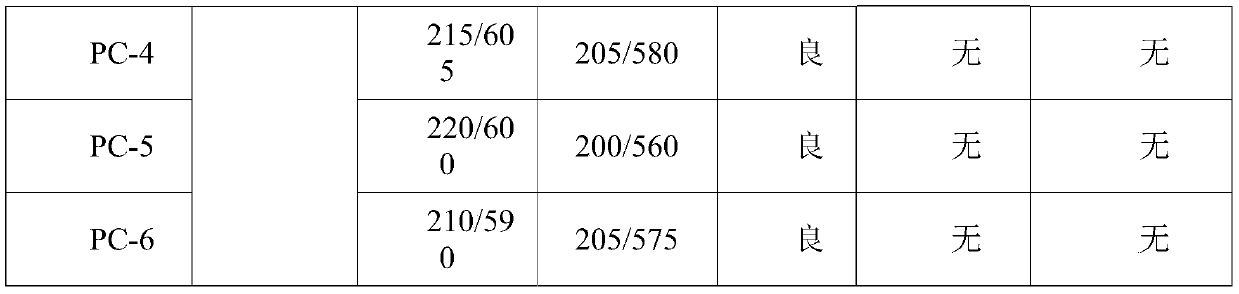

Embodiment 1

[0046] Put 100.00 parts of HPEG monomer with a molecular weight of 2400, 3 parts of a special ester macromonomer with a molecular weight of 1000 and 80 parts of water into a reaction vessel, heat up, stir to completely dissolve the reactants, heat up to 30°C, and add hydrogen peroxide 1.9 parts, drop 14 parts of acrylic acid and 5 parts of water mixed solution A, 1.2 parts of vitamin C, 0.4 parts of mercaptoethanol and 17 parts of water mixed solution B, where A solution is dripped at 210±20min, B mixed solution at 180 ±20min to finish dripping. After the dropwise addition, stir and keep warm for 1 hour, add 40 parts of water, cool down to below 30°C, adjust the pH value to 6.5 with sodium hydroxide, and obtain super early strength polycarboxylate high-performance concrete superplasticizer PC-1.

Embodiment 2

[0048] Put 100.00 parts of HPEG monomer with a molecular weight of 2400, 5 parts of a special ester macromonomer with a molecular weight of 1000 and 80 parts of water into a reaction vessel, heat up, stir to completely dissolve the reactants, heat up to 30°C, and add hydrogen peroxide 1.9 parts, drop 14 parts of acrylic acid and 5 parts of water mixed solution A, 1.2 parts of vitamin C, 0.4 parts of mercaptoethanol and 17 parts of water mixed solution B, where A solution is dripped at 210±20min, B mixed solution at 180 ±20min to finish dripping. After the dropwise addition, stir and keep warm for 1 hour, add 40 parts of water, cool down to below 30°C, adjust the pH value to 6.5 with sodium hydroxide, and obtain super early strength polycarboxylate high-performance concrete water reducer PC-2.

Embodiment 3

[0050] Put 100.00 parts of HPEG monomer with a molecular weight of 2400, 7 parts of special ester macromonomer with a molecular weight of 1000 and 80 parts of water into a reaction vessel, heat up, stir to completely dissolve the reactants, heat up to 30°C, and add hydrogen peroxide 1.9 parts, drop 12 parts of acrylic acid and 5 parts of water mixed solution A, 1.2 parts of vitamin C, 0.4 parts of mercaptoethanol and 17 parts of water mixed solution B, where A solution is dripped at 210±20min, B mixed solution at 180 ±20min to finish dripping. After the dropwise addition, stir and keep warm for 1 hour, add 40 parts of water, cool down to below 30°C, adjust the pH value to 6.5 with sodium hydroxide, and obtain super early strength polycarboxylate high-performance concrete water reducer PC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com