Composite negative electrode material, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of negative electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of negative electrode material cycle performance and rate performance that need to be improved, and achieve low preparation difficulty, short process and controllable cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment prepares the composite negative electrode material according to the following method:

[0055] Take 1.5kg of SiO powder, put it into a 5L experimental batch rotary CVD furnace, and pass nitrogen gas into the furnace to replace the atmosphere. After the oxygen content in the exhaust gas is lower than 200ppm, start to heat up while continuously feeding nitrogen gas. After the temperature was raised to 900°C, 0.8 L / min of methane was introduced with nitrogen as the carrier gas, and the reaction pressure was kept at 1.2 atm. After the reaction was continued for 6 hours, the methane gas was cut off, and the temperature was naturally lowered to obtain the composite negative electrode material.

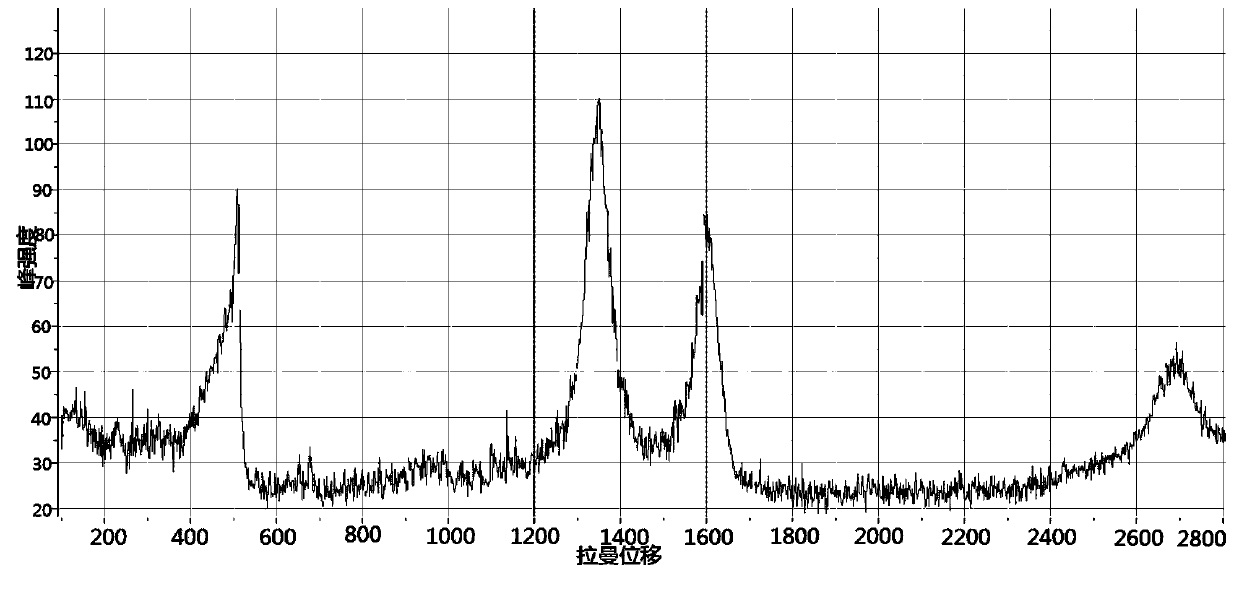

[0056] After the negative electrode material is discharged, it is broken up and sieved, and the Raman spectrum test is carried out (the XPLORA laser confocal Raman spectrometer of Japan HORIBA is adopted, the laser wavelength is 532nm, and the test range is 100cm -1 to...

Embodiment 2

[0062] This embodiment prepares the composite negative electrode material according to the following method:

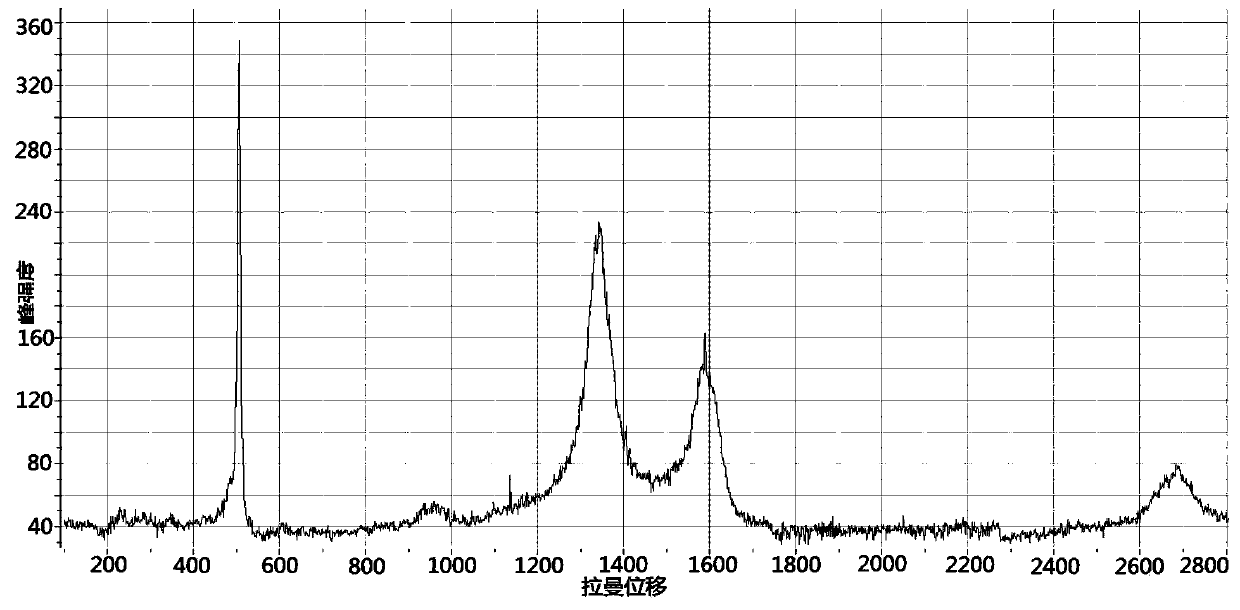

[0063] Take 150g of porous silicon powder (specifically >150cm 2 / g), join in the 5L experimental type batch-type rotary CVD furnace, feed nitrogen into the furnace to carry out atmosphere replacement, after the oxygen content in the exhaust gas is lower than 200ppm, start to heat up under the situation of continuously feeding nitrogen, be heated up to After 935° C., 1.0 L / min of methane was introduced with nitrogen as the carrier gas, and the reaction pressure was kept at 2.0 atm. After the reaction was continued for 10 hours, the methane gas was cut off, and the temperature was naturally lowered to obtain the composite negative electrode material.

[0064] After the negative electrode material was discharged, it was broken up and sieved for testing.

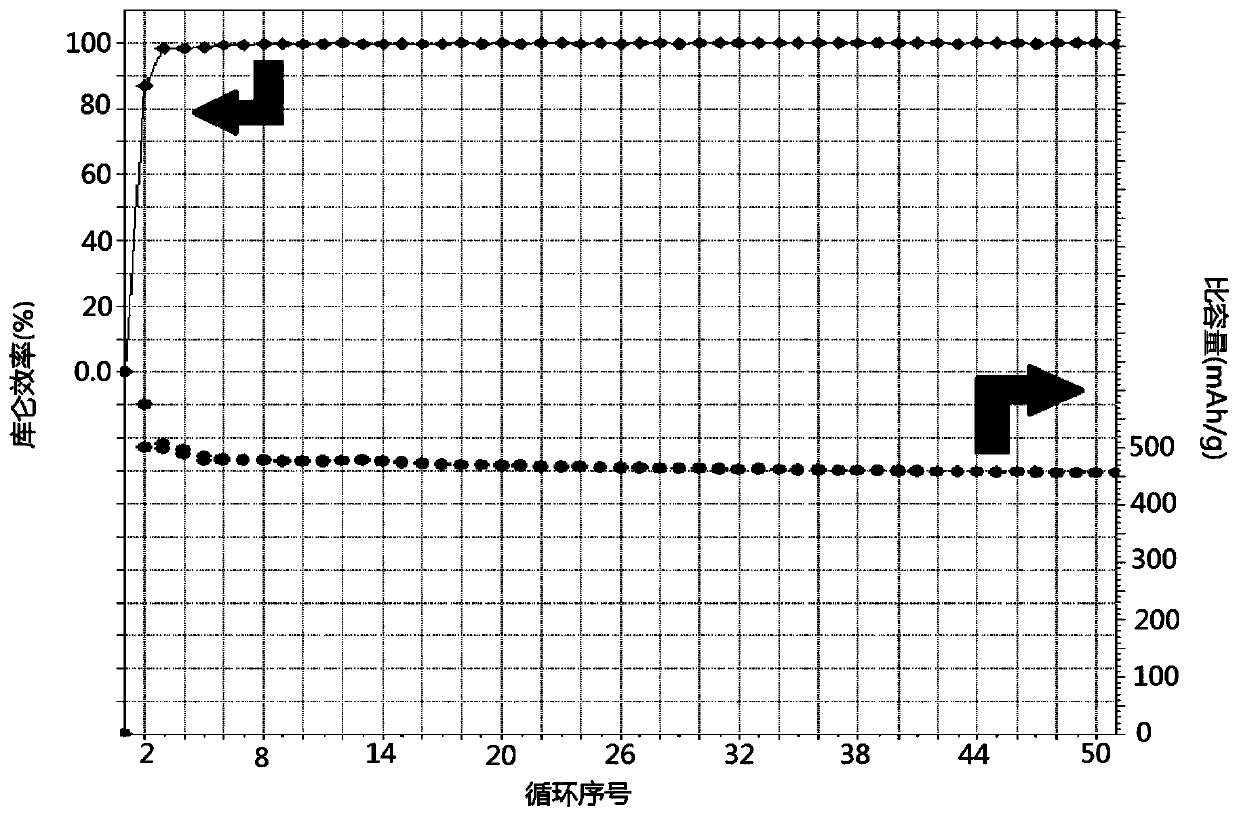

[0065] The negative electrode material prepared in this embodiment includes a porous silicon inner core and an inor...

Embodiment 3

[0070] Take 1.5kg of SiO powder, put it into a 5L experimental batch rotary CVD furnace, and pass nitrogen gas into the furnace to replace the atmosphere. After the oxygen content in the exhaust gas is lower than 200ppm, start to heat up while continuously feeding nitrogen gas. After heating up to 700°C, use nitrogen as the carrier gas to feed 1.8L / min of a mixture of acetylene and hydrogen (the molar ratio of acetylene to hydrogen is 2:1), keep the reaction pressure at 1.0atm, continue the reaction for 16h, and then cut off The mixed gas begins to cool down naturally to obtain the composite negative electrode material.

[0071] The negative electrode material prepared in this embodiment includes a SiO inner core and an inorganic carbon material coating layer coated on the SiO inner core, and the mass fraction of the coating layer is 4.3%. The Raman spectrum peak A of the negative electrode material prepared in this embodiment is at 503cm -1 , peak B is at 1351cm -1 , peak C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com