Multi-strain double-fermented black bean soy sauce and brewing method of soy sauce

A multi-strain, black bean technology, applied in the directions of yeast-containing food ingredients, food ingredient functions, food science, etc., can solve the problems of not much influence of soy sauce aroma, lack of nutrition and functionality, and lack of innovative technology, so as to achieve soy sauce. The effect of outstanding fragrance, strong body and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

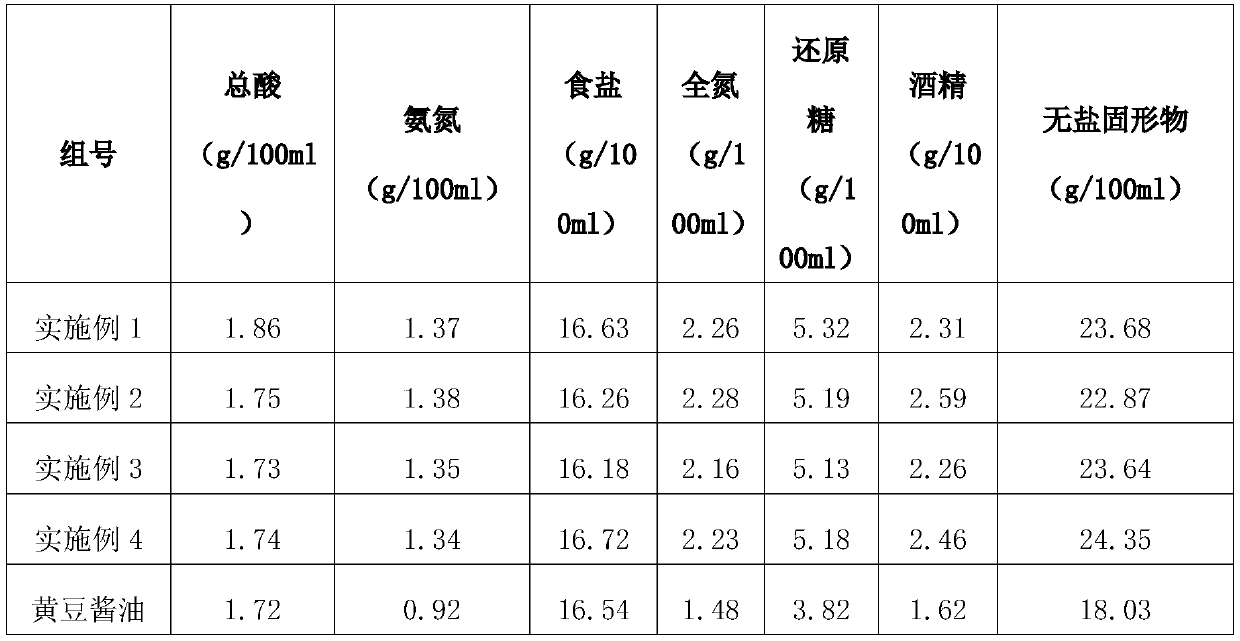

Examples

Embodiment 1

[0022] The brewing method of multi-strain double-fermented black bean soy sauce comprises the following steps:

[0023] A. Raw material processing

[0024] After the black beans are screened and impurity removed, they enter the roller press equipment for crushing. The crushing requirements are: a black bean is crushed into 0-5 pieces; after crushing, the watering operation is carried out according to the volume ratio of 1:1.1, and the watering temperature is 70-80 ℃ , the moisturizing time is 8-10min;

[0025] The fried wheat is roasted and then pulverized, and the amount of powder that passes through a 30-mesh sieve is required to reach 40%;

[0026] B. to make music

[0027] Using NK type cooking device, steam the black beans after moisturizing and crushing at a temperature of 128-130°C and a pressure of 0.16-0.18Mpa for 6-7min; after rapid decompression and cooling, according to the mass ratio of black beans: fried wheat = 8:2 Add the crushed fried wheat, then add black ...

Embodiment 2

[0032] Example 2 was carried out with reference to Example 1.

[0033] The difference lies in that, in step A, after the black beans are broken, the moisturizing operation is carried out according to the volume ratio of 1:1.2; the fried wheat is roasted and then pulverized, and the amount of powder that passes through a 30-mesh sieve is required to reach 50%;

[0034] In step B, the black beans after moistening and crushing are steamed for 5 minutes at a temperature of 128-130 ° C and a pressure of 0.18-0.20 Mpa; after rapid decompression and cooling, the crushed black beans are added in a ratio of 9:1 according to the mass ratio of black beans: fried wheat. Stir-fry wheat, then add black beans and Aspergillus oryzae with a total mass of 3‰ of the fried wheat, mix them evenly, and transport them to the koji bed for ventilation koji-making; in the early stage of koji-making, the temperature should be controlled within the range of 24-26°C, and the humidity should be above 90%; ...

Embodiment 3

[0037] Example 3 was carried out with reference to Example 1.

[0038] The difference lies in that, in step A, after the black beans are broken, the moisturizing operation is carried out according to the volume ratio of 1:1.1; the fried wheat is roasted and then pulverized, and the amount of powder that passes through a 30-mesh sieve is required to reach 30%;

[0039] In step B, the black beans after moistening and crushing are steamed for 9 minutes at a temperature of 128-130 ° C and a pressure of 0.14-0.16 Mpa; after rapid decompression and cooling, the crushed black beans are added in the ratio of black beans: fried wheat=6:4 by mass. Stir-fry wheat, then add black beans and Aspergillus oryzae with a total mass of 5‰ of the fried wheat, mix them evenly, and transport them to the koji bed for ventilation koji making; in the early stage of koji making, the temperature should be controlled within the range of 24-26°C, and the humidity should be above 90%; In the middle stage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com