Petroleum hydrocarbon cracking catalyst and preparation method thereof

A cracking catalyst and petroleum hydrocarbon technology are applied in the field of petroleum hydrocarbon cracking catalysts and their preparation, which can solve the problems of difficulty in reusing materials, increase waste treatment procedures, and high use costs, and achieve convenient access, high-efficiency preparation, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

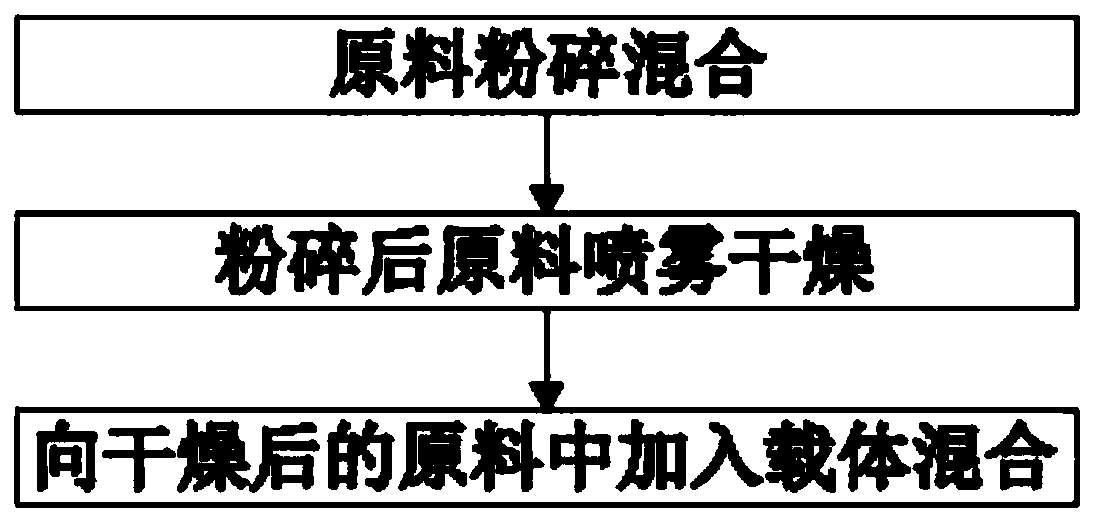

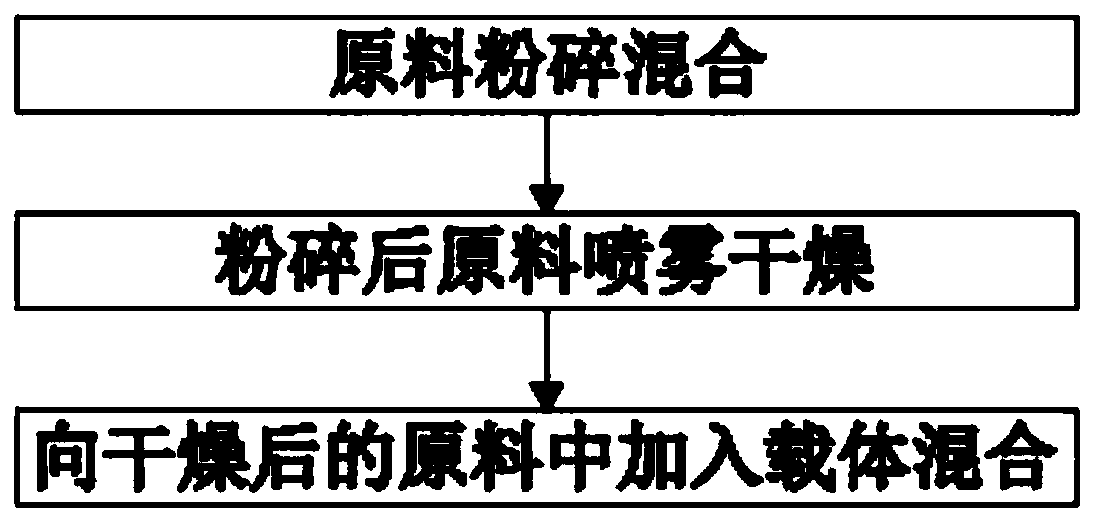

[0032] A kind of preparation method of petroleum hydrocarbon cracking catalyst, the preparation method concrete steps of this petroleum hydrocarbon cracking catalyst are as follows:

[0033] S1: Crushing and mixing of raw materials: put the raw materials Y-type molecular sieve, zeolite, clay, and catalyst waste residue in the pulverizing equipment, pulverize and mix the raw materials, and the stirring and pulverizing speed of the pulverizing equipment is 400-500r / min to disperse the raw materials evenly;

[0034] S2: Spray drying of raw materials after pulverization: drying the uniformly dispersed raw materials in step S1 by spray drying equipment, so that the dried raw materials are in granular form;

[0035] S3: adding the carrier to the dried raw material and mixing: adding the carrier to the dried raw material in step S2 and continuing to mix evenly.

Embodiment 1

[0037] The preparation method concrete steps of this petroleum hydrocarbon cracking catalyst are as follows:

[0038] The raw materials of the petroleum hydrocarbon cracking catalyst are as follows according to mass proportion: 30g of Y-type molecular sieve, 22g of zeolite, 14g of clay, 34g of carrier and 20g of catalyst waste residue;

[0039] S1: Crushing and mixing of raw materials: put the raw materials Y-type molecular sieve, zeolite, clay, and catalyst waste residue in the crushing equipment, and grind and mix the raw materials. The molecular sieve is ultra-stable Y, rare earth ultra-stable Y, rare earth Y or rare earth HY molecular sieve, the zeolite is rare earth Y-type zeolite, and the clay is kaolin or metakaolin;

[0040] S2: Spray drying of raw materials after pulverization: drying the uniformly dispersed raw materials in step S1 by spray drying equipment, so that the dried raw materials are in granular form;

[0041] S3: adding the carrier to the dried raw materi...

Embodiment 2

[0043] The preparation method concrete steps of this petroleum hydrocarbon cracking catalyst are as follows:

[0044] The raw materials of the petroleum hydrocarbon cracking catalyst are as follows according to mass proportion: 35g of Y-type molecular sieve, 23g of zeolite, 15g of clay, 35g of carrier and 23g of catalyst waste residue;

[0045] S1: Crushing and mixing of raw materials: put the raw materials Y-type molecular sieve, zeolite, clay, and catalyst waste residue in the crushing equipment, and grind and mix the raw materials. The molecular sieve is ultra-stable Y, rare earth ultra-stable Y, rare earth Y or rare earth HY molecular sieve, the zeolite is rare earth Y-type zeolite, and the clay is kaolin or metakaolin;

[0046] S2: Spray drying of raw materials after pulverization: drying the uniformly dispersed raw materials in step S1 by spray drying equipment, so that the dried raw materials are in granular form;

[0047] S3: adding the carrier to the dried raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com