RTM forming mold and method of composite blade

A technology for forming molds and composite materials, which is applied in household appliances, other household appliances, household components, etc., can solve the problems of increasing the difficulty of RTM molding, short effective injection period, uneven distribution of resin flow, etc., and achieve a good RTM process. adaptability, reduce the risk of resin implosion, and reduce the effect of edge effect phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

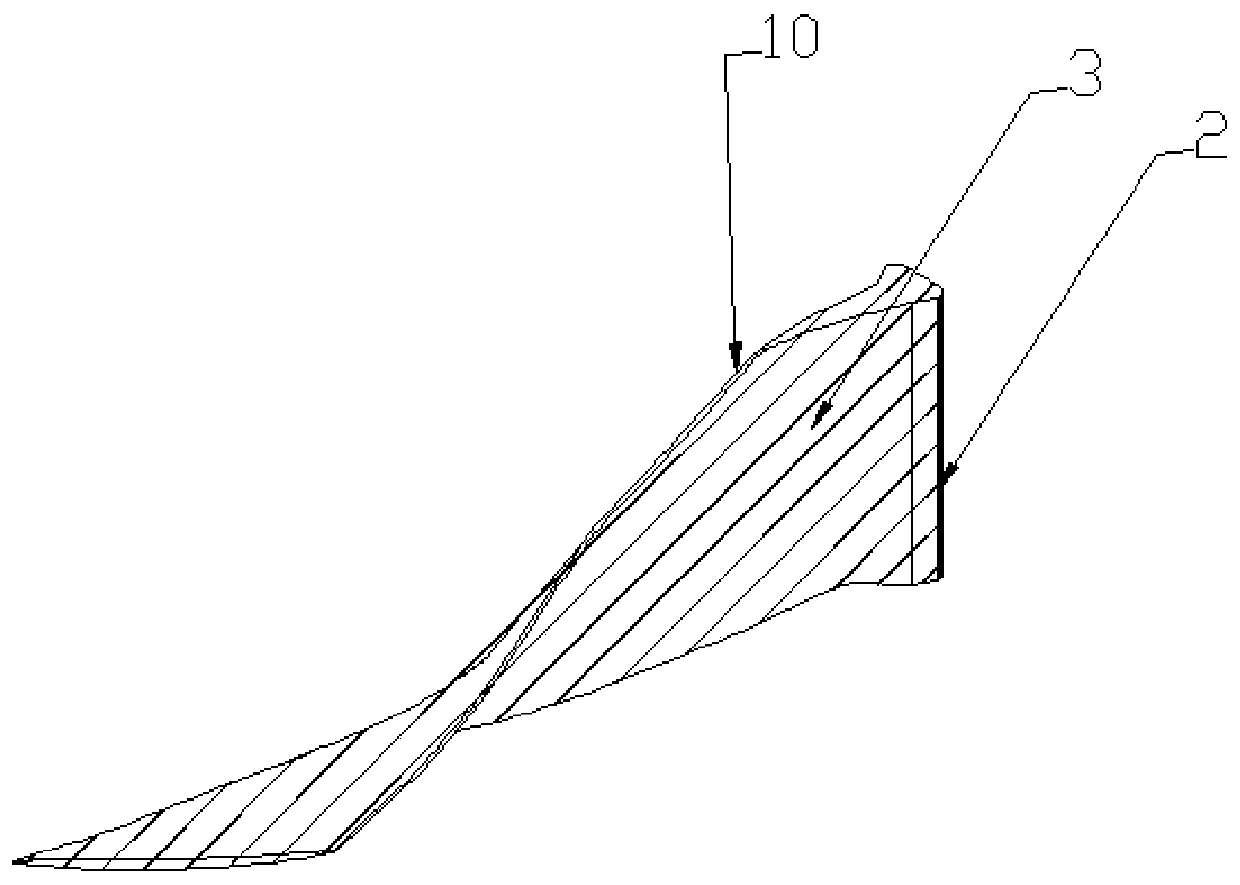

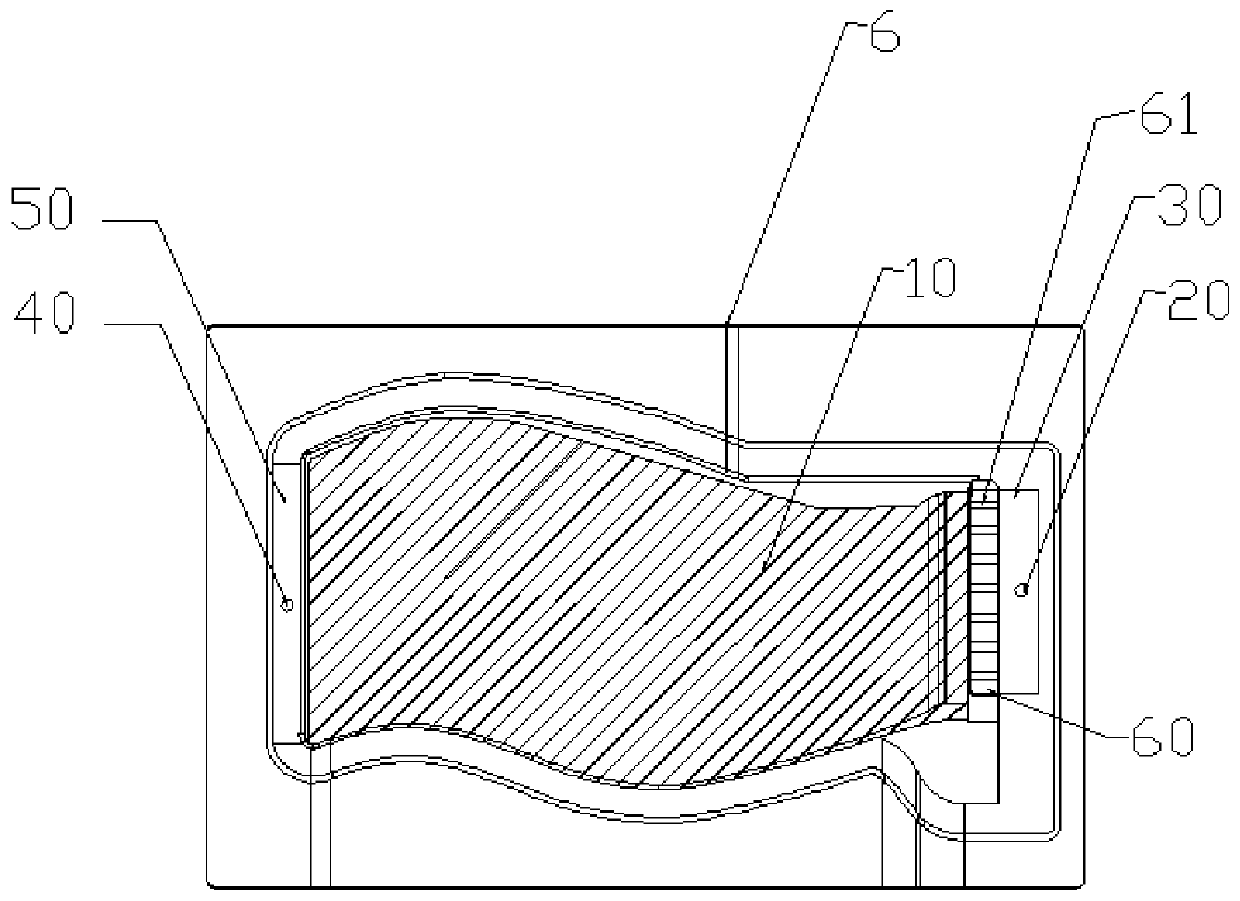

[0028] The blade prefabricated body 10 is a fan blade prefabricated body with a variable thickness 2.5D woven structure. It is an intermediate body before RTM molding during processing. The blade 1 is composed of a tenon 2 and a blade body 3. The material is CCF800, and the fiber volume content of the material is 58 %±3%; among them, CCF800 is T800 carbon fiber fabric with a specification of 12K produced by Shandong Weihai Development Co., Ltd., and the resin for injection is ACTECH1304 high-toughness liquid molding resin of AVIC Composites Co., Ltd., and the external dimension of blade preform 10 is 780mm× 320mm (length × width), the specific molding steps are as follows:

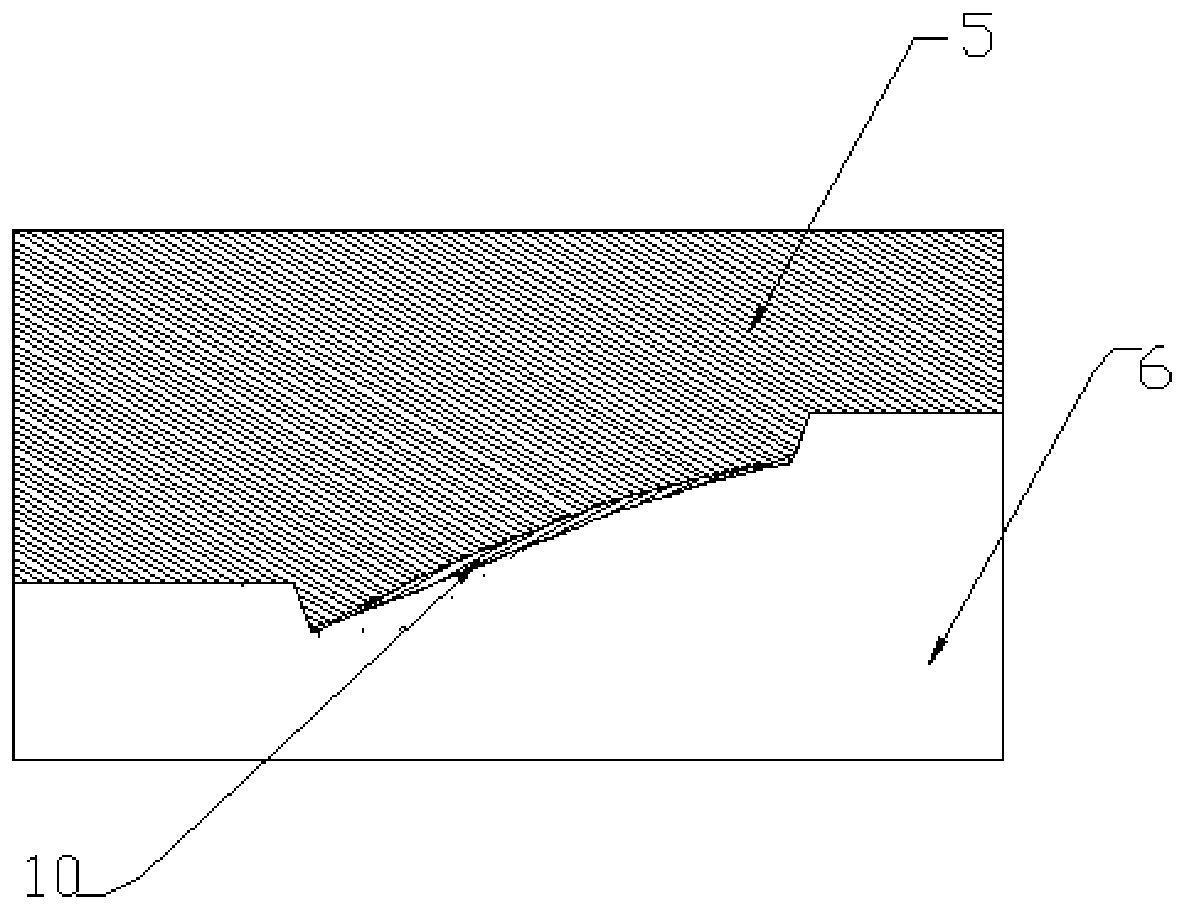

[0029] 1) The forming die 4 is processed from a metal blank, and the forming die 4 is composed of an upper half-mold 5 and a lower half-mold 6, wherein the upper half-mold 5 is a convex die, and the lower half-mold 6 is a concave die;

[0030] 2) At the front end of the lower half-mold 6, there are glue in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com